Automatic control system for distillation process in baijiu making

A technology of automatic control and distillation process, applied in the preparation of alcoholic beverages, etc., can solve the problems of in-depth fermentation, distillation, etc., and achieve the effect of improving control quality, improving production level, and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

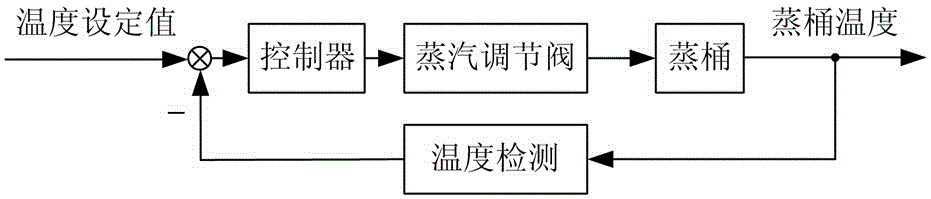

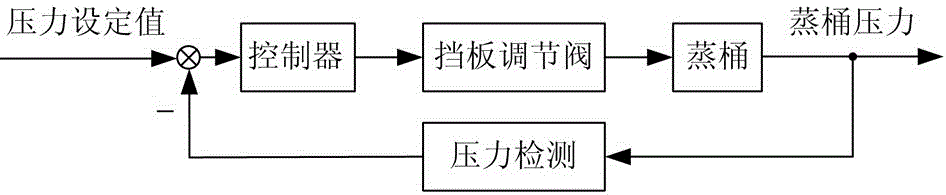

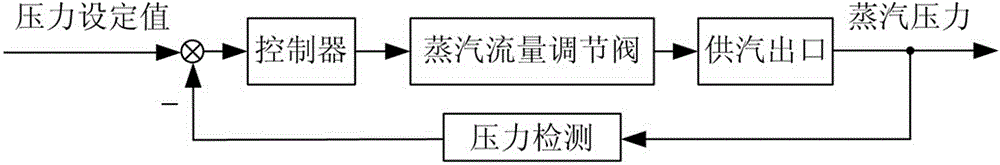

[0030]The automatic control system of the liquor distillation process proposed by the present invention involves control loop instruments including: water inlet regulating valve and air inlet regulating valve (the original manual adjustment of water inlet valve and steam inlet valve is changed to automatic regulating valve), in the steam The baffle plate installed at the outlet of the barrel is used to adjust the pressure inside the steam barrel; the detection device (newly added) for the temperature, pressure, water inlet temperature and outlet temperature of the steam barrel can realize the Continuous adjustment of process parameters such as pressure. A baffle is installed at the outlet of the steaming barrel to separate the temperature and pressure in the steaming barrel and realize individual adjustment. When there is only one control value of the steam valve, the steam flow and the pressure in the barrel cannot be adjusted independently.

[0031] steamer side

[0032]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com