Low-compression-ratio and thick-specification X70-grade gas transmission pipeline steel and production method

A technology with low compression ratio and thick specification, applied in the field of X70 grade gas pipeline steel and production field with low compression ratio and thick specification, it can solve the problems of less production line, high cost and insufficient thickness of 150mm continuous casting billet, so as to improve market competitiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

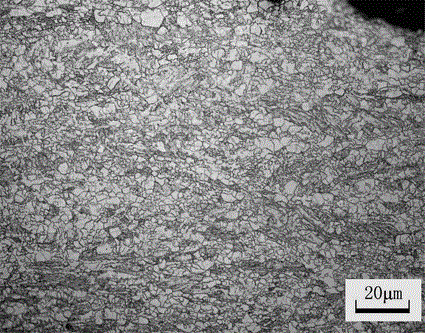

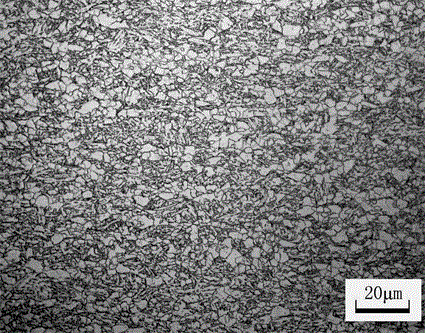

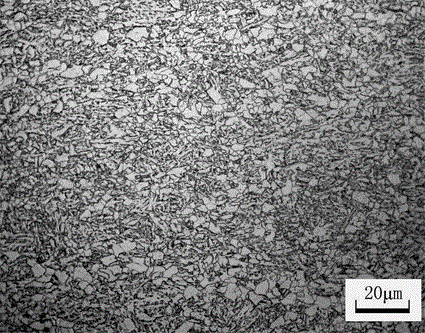

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below:

[0035] Table 1 is a list of values of various embodiments of the present invention;

[0036] Table 2 is the list of main process parameters of each embodiment of the present invention;

[0037] Table 3 is the horizontal main performance detection statistical table of each embodiment of the present invention.

[0038] Each embodiment of the present invention is produced according to the following steps:

[0039] 1) Heating the slab with a thickness of 225-235mm, the heating temperature is controlled at 1120-1180°C, and the soaking time is not less than 40 minutes, and the total heating time is not less than 250 minutes;

[0040] 2) Rough rolling is carried out, and the rolling temperature in the recrystallization zone is controlled at 1050-1115°C. During the deformation process, the maximum rolling force is used for rolling, and the maximum rolling force is not less than 7500t; the deformation rate is controlled a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com