Heavy-load type durable asphalt composite structure

A composite structure and durability technology, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve the problems of poor anti-heavy load capacity, inconsistent force and deformation, inconsistency, etc., and achieve flatness Good, excellent water sealing effect, high friction coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

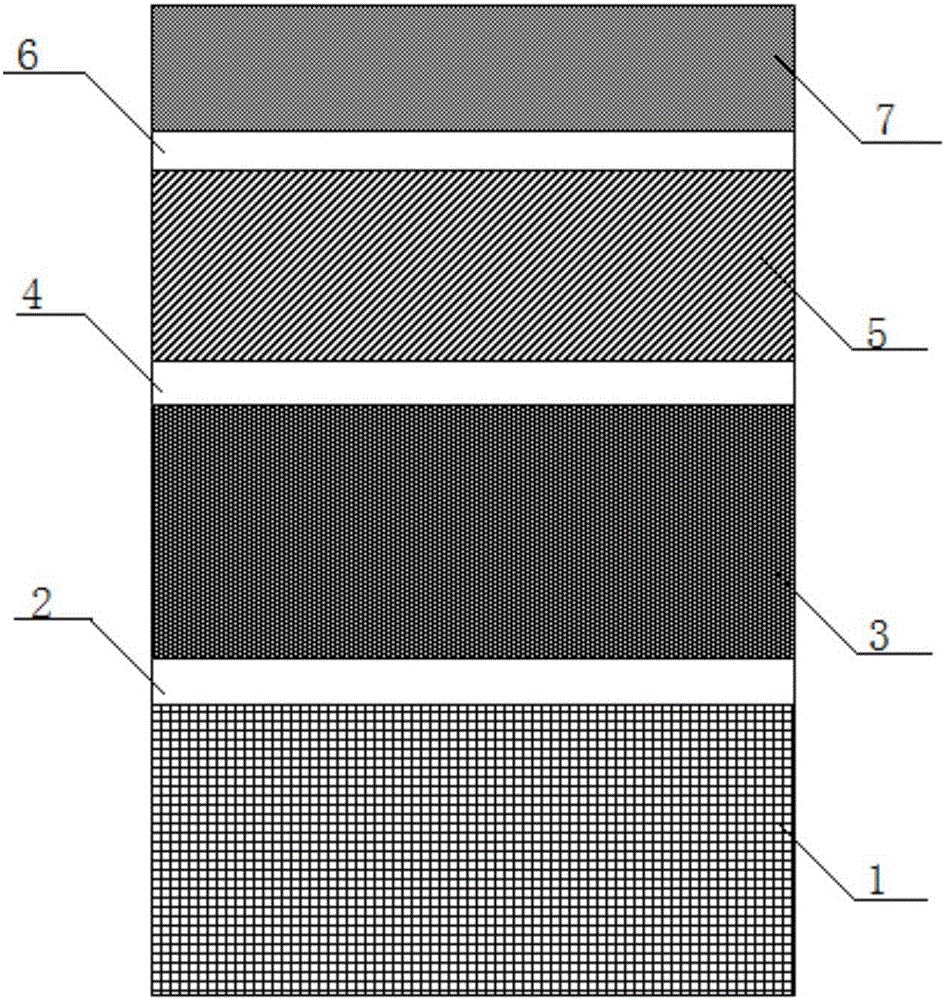

[0025] Such as figure 1 The schematic diagram of the heavy-duty durable asphalt composite structure of the present invention is shown, and a stress-absorbing layer 2, a lower layer 3, a first adhesive layer 4, a middle surface layer 5, and a second adhesive layer 6 are also arranged on the top of the original pavement layer 1. and layer 7 above.

[0026] Wherein the stress absorbing layer 2 is directly arranged on the upper surface of the original pavement layer 1, the stress absorbing layer 2 is a densely graded AC05 structure with a thickness of 1.5cm, and the porosity is 1.5%, wherein the amount of ordinary asphalt is 8-10%, and the amount of aggregate is 90-92%, 88-92% of aggregates with a particle diameter of 2.36-4.75mm, and 8-12% of particles with a particle diameter below 2.36mm. The stress absorbing layer 2 is arranged between the lower layer 3 and the original cement concrete pavement layer, which can effectively prevent and delay reflection cracks caused by cracks ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com