Variable-rigidity foundation pit support structure

A technology of foundation pit support and variable stiffness, which is applied in the direction of infrastructure engineering, excavation, construction, etc., can solve the problems of low material bending capacity, complicated process, high construction requirements, etc., and achieve good anti-dumping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

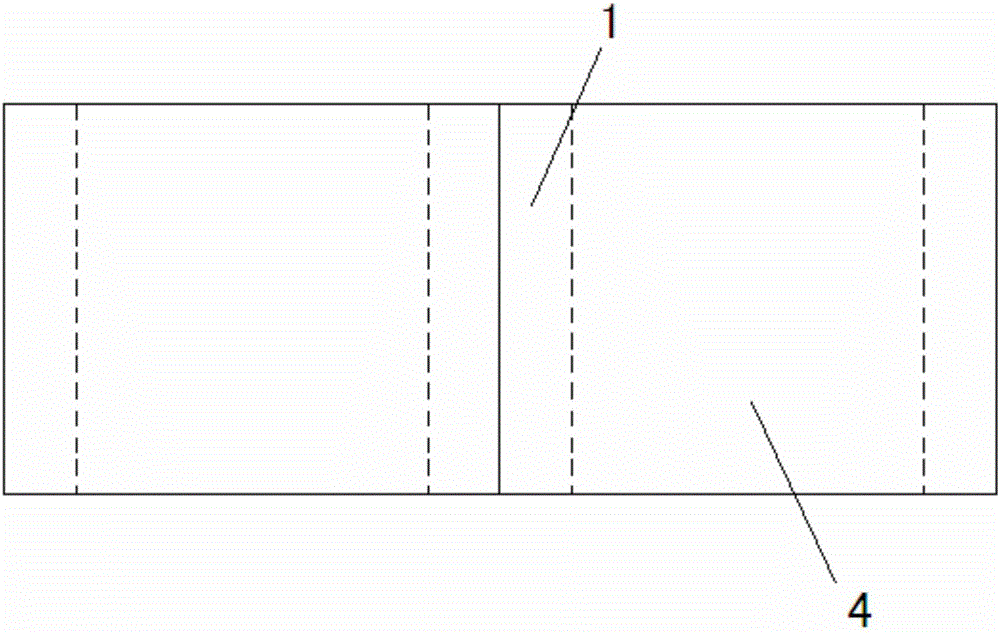

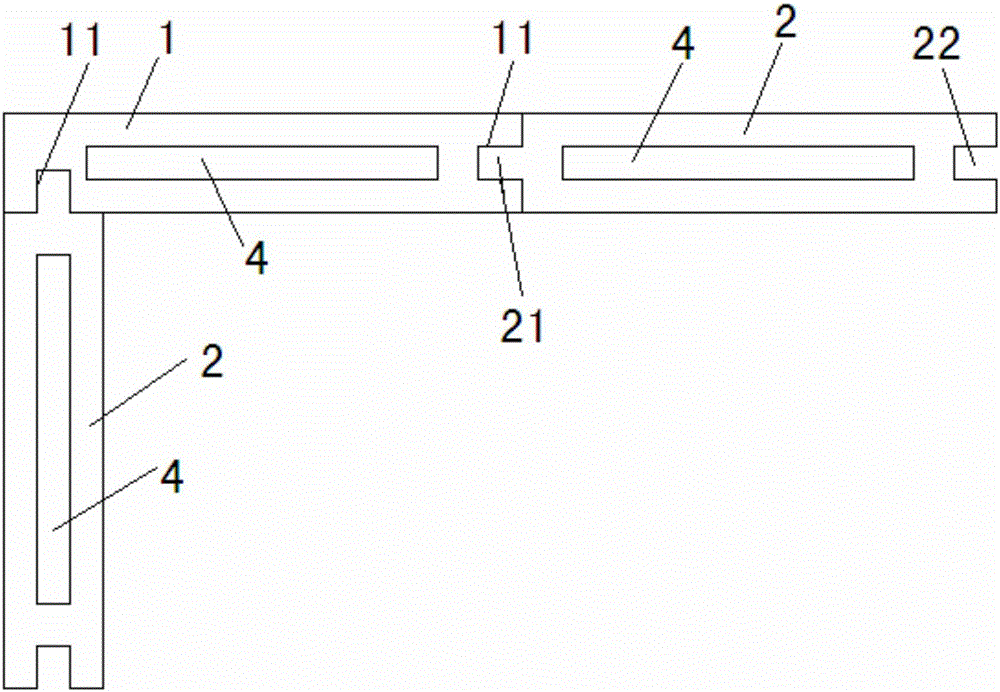

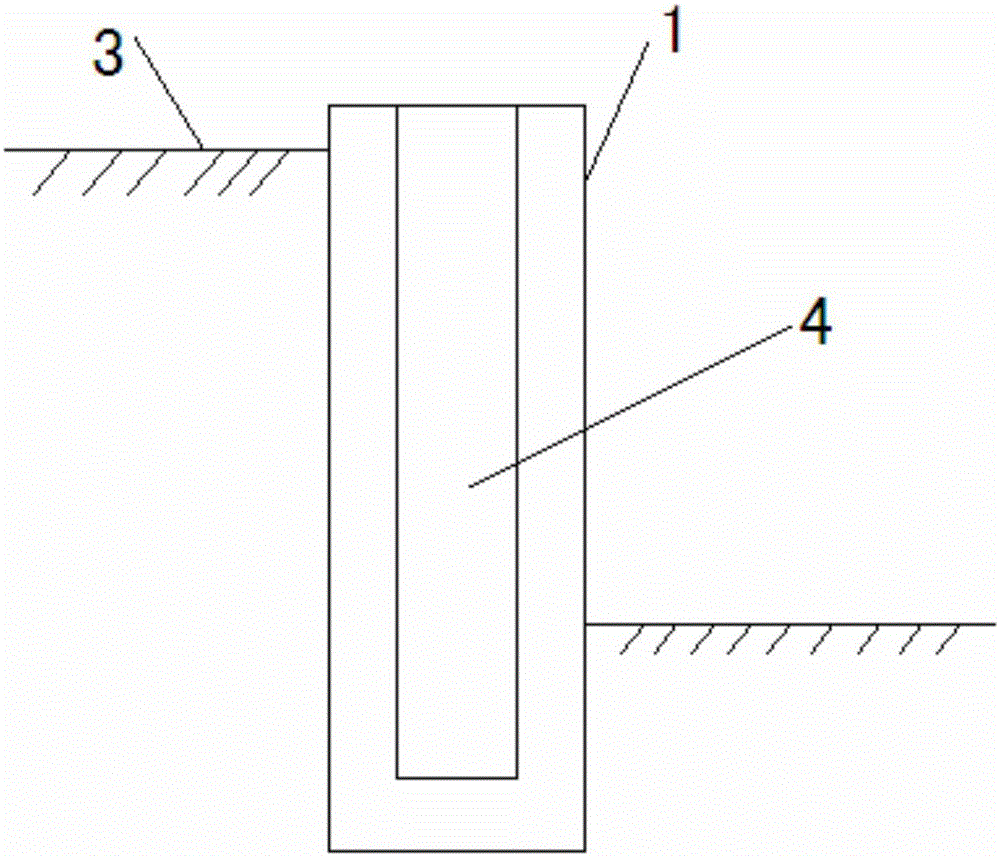

[0017] Embodiment 1 A foundation pit support structure with variable stiffness according to the present invention includes a first plastic plate 1 and at least two second plastic plates 2, and the two ends of the first plastic plate 1 are respectively connected to the corresponding One end of the second plastic plate 2 is connected to form a downward knuckle, and the other end of the second plastic plate 2 is connected to the remaining second plastic plate 2. The first plastic plate 1 and the second plastic plate 2 are connected to form a An inverted L-shaped structure placed in the foundation pit; the first plastic plate 1 and the second plastic plate 2 are provided with a hollow structure 4 for buffering; the entire inverted L-shaped structure is inserted into the foundation pit 3 along the wall of the foundation pit ground.

[0018] The first plastic plate 1 and the second plastic plate 2, or two connected second plastic plates 2 are connected in a plug-in manner, and one e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com