Construction method of drilling bolt fastener type formwork supporting system

A formwork support and construction method technology, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, which can solve the problem of occupying construction space, shortening service life, The installation process is complex and other problems, to achieve the effect of maintaining cleanliness, stable structure, and simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

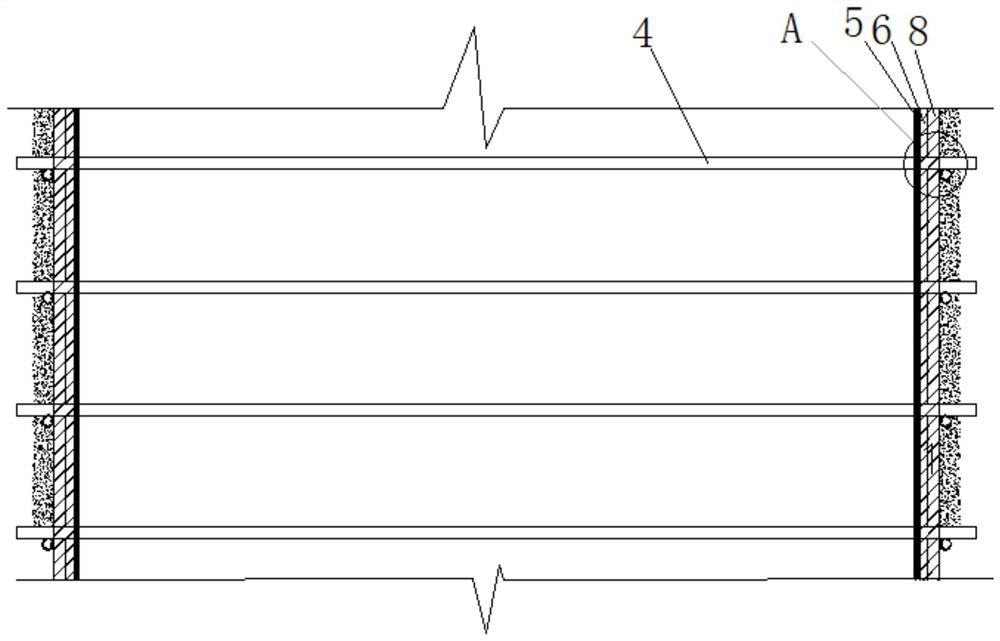

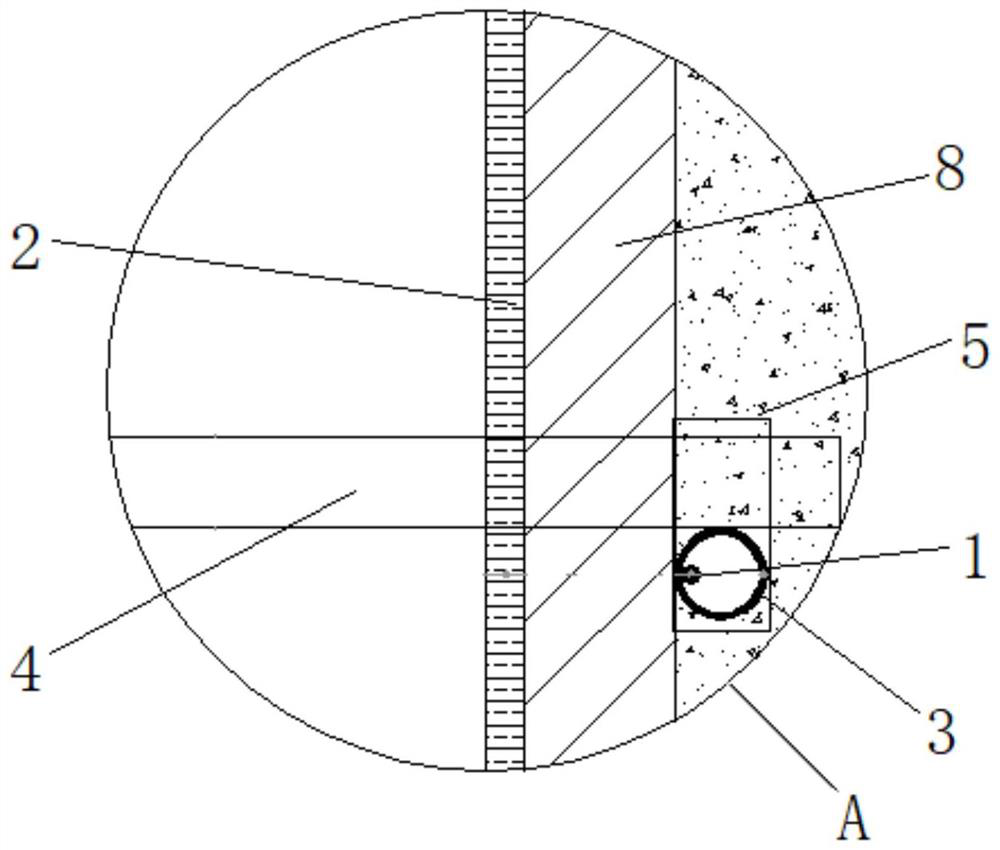

[0058] In a construction project, it is necessary to pour the top beam of the foundation pit, and the size of the top beam of the foundation pit is 3400 (width) * 600 (height) mm.

[0059] Step 1: Construction preparation, prepare materials for the formwork support system of drilled bolt fasteners, including inserting ribs 1, side formwork 2, positioning pipe 3, connecting pipe 4, bolt fastener 5, square corrugation 6 and reinforcement pipe 8.

[0060] Step 2: Use an ink fountain to pop out the 3400mm centerline of the foundation pit topping beam on the cushion layer 7, take the 3400mm centerline as the reference, measure 1700mm to one side and use the spring line as the component side line of one side of the foundation pit topping beam, and move to the other side Measure 1700mm from the side and snap the line as the component edge on the other side of the foundation pit top beam.

[0061] In the present embodiment, the side formwork 2 adopts plywood with a thickness of 18mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com