Anti-haze carbon fiber window screen and method for manufacturing same

An anti-fog and carbon fiber technology, applied in the field of screen windows, can solve the problems of reduced visibility, disorganized structure, unsatisfactory comprehensive effect of anti-fog screen windows, etc., and achieves excellent filtering effect, good air permeability, good anti-fog effect and mechanics. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

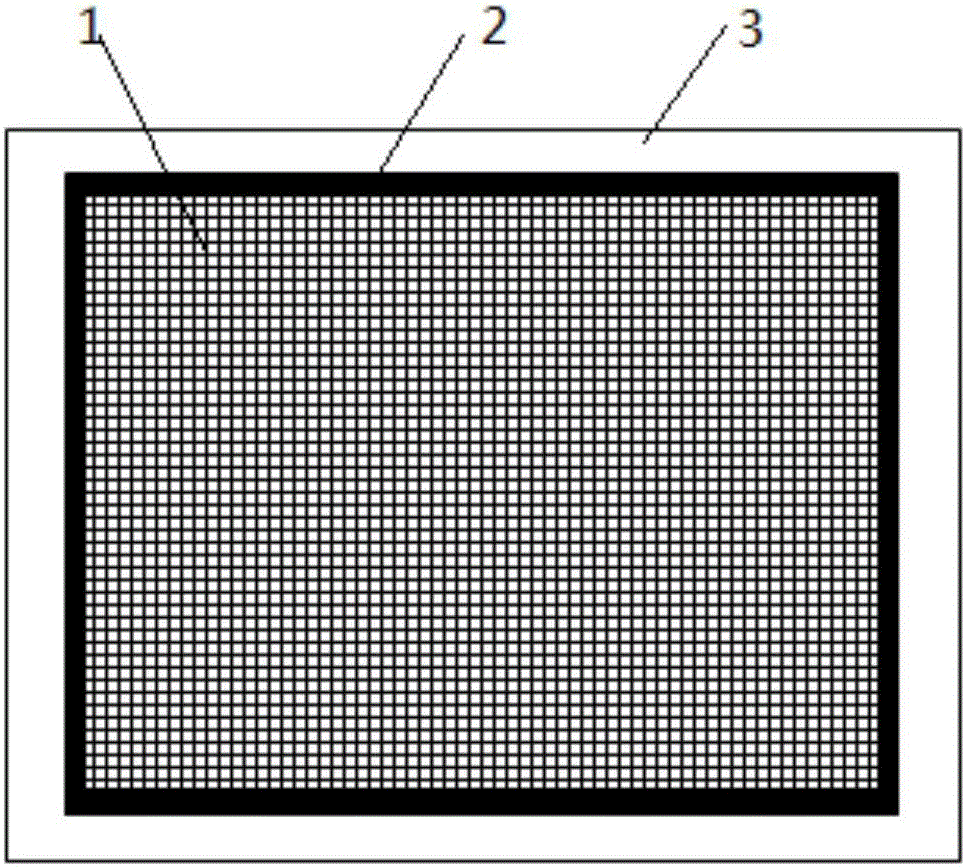

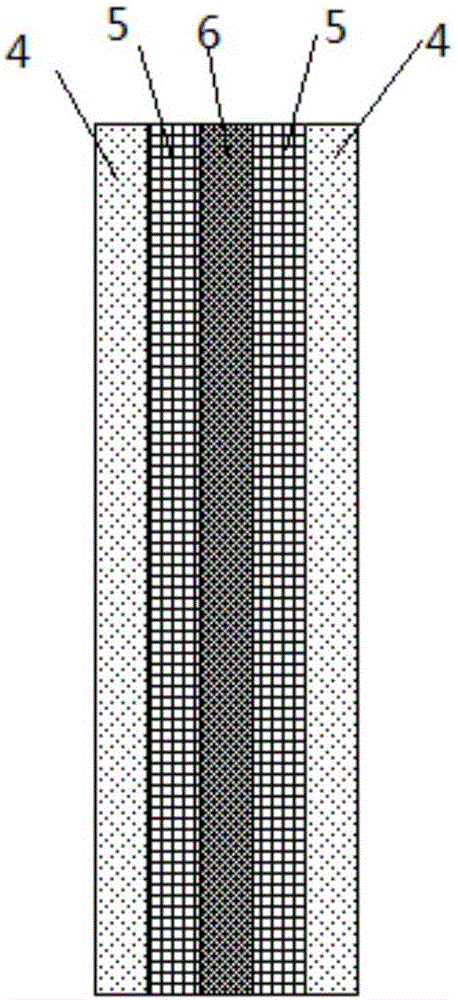

[0034] Such as figure 1 with 2As shown, a haze adsorption screen window with a superimposed structure of an organic fiber melt-blown non-woven fabric layer and an activated carbon fiber adsorption layer, the screen window includes a screen window main body 1, a magnetic suction strip 2 is provided along the edge of the screen window main body, and the magnetic suction strip is provided outside The screen window frame 3; wherein, the screen window main body includes an activated carbon fiber felt filter adsorption layer 6, and a metal fiber mesh cloth layer 5 and an organic fiber non-woven fabric layer 4 are sequentially and symmetrically arranged on both sides of the activated carbon fiber felt filter adsorption layer.

[0035] The preparation of a smog adsorption screen window with a laminated structure of an organic fiber melt-blown non-woven fabric layer and an activated carbon fiber adsorption layer comprises the following steps:

[0036] First, the preparation of the org...

Embodiment 2

[0042] The preparation of a smog adsorption screen window with a laminated structure of an organic fiber melt-blown non-woven fabric layer and an activated carbon fiber adsorption layer comprises the following steps:

[0043] First, the preparation of the organic fiber meltblown nonwoven layer. Polypropylene fiber is selected as the fiber raw material of the non-woven fabric layer, and the surface density of the non-woven fabric is 50g / m 2 .

[0044] Second, the preparation of the metal fiber mesh cloth layer. Copper fiber is selected as the fiber material of the metal fiber mesh cloth layer, and the mesh number of the metal mesh cloth is 900 mesh.

[0045] Third, the preparation of the intermediate activated carbon fiber adsorption layer. The thickness of the activated carbon fiber felt adsorption layer is 2mm (area density: 150g / m 2 ), the adsorption capacity is determined by the specific surface area, and its specific surface area is 1200m 2 / g.

[0046] Fourth, symme...

Embodiment 3

[0049] The preparation of a smog adsorption screen window with a laminated structure of an organic fiber melt-blown non-woven fabric layer and an activated carbon fiber adsorption layer comprises the following steps:

[0050] First, the preparation of the organic fiber meltblown nonwoven layer. Polyethylene fiber is selected as the fiber material of the non-woven fabric layer, and the surface density of the non-woven fabric is 50g / m 2 .

[0051] Second, the preparation of the metal fiber mesh cloth layer. Aluminum fiber is selected as the fiber material of the metal fiber mesh cloth layer, and the mesh number of the metal mesh cloth is 200 mesh.

[0052] Third, the preparation of the intermediate activated carbon fiber adsorption layer. The thickness of the activated carbon fiber felt adsorption layer is 3mm (area density: 200g / m 2 ), the adsorption capacity is determined by the specific surface area, and its specific surface area is 1400m 2 / g.

[0053] Fourth, symmetri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap