Fast drilling bridge plug made of composite material

A composite material and bridge plug technology, which is used in earth-moving drilling, wellbore/well components, sealing/packaging, etc. The effect of improving construction efficiency, shortening fracturing operation time, and saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

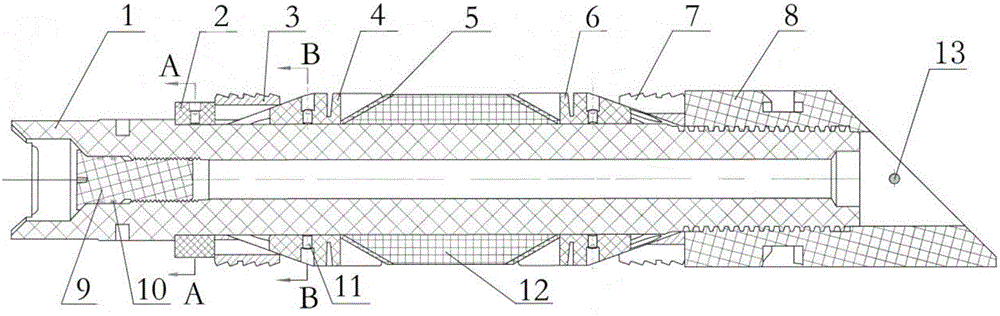

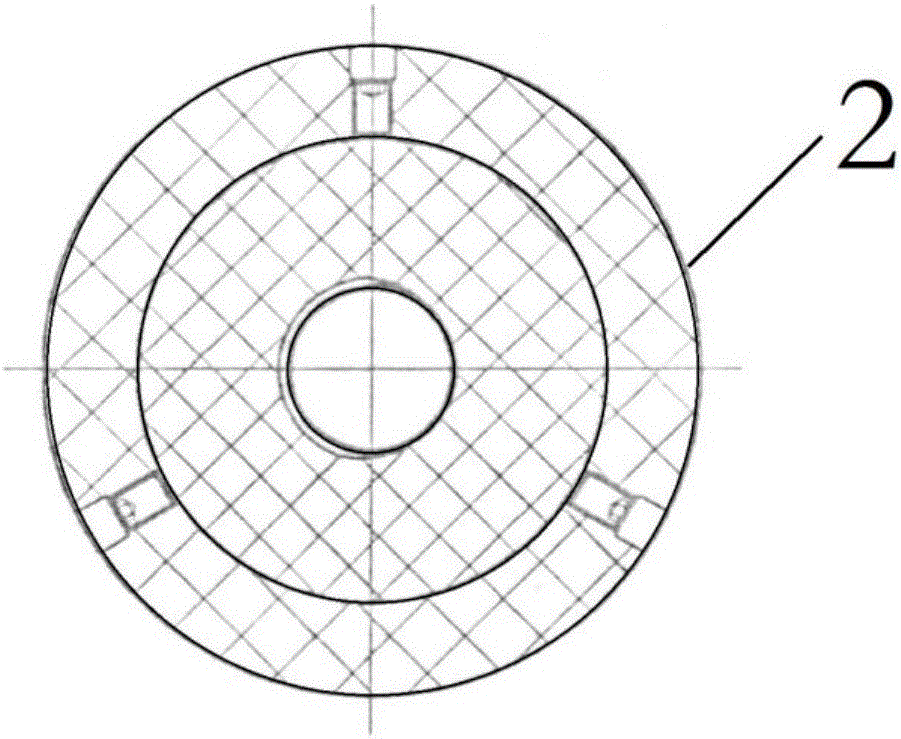

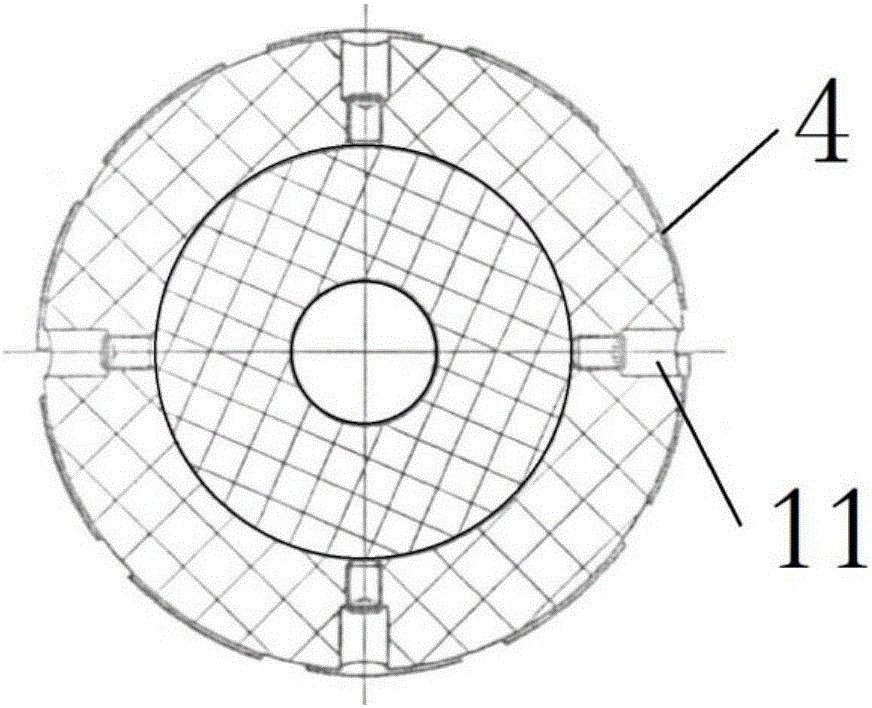

[0024] The present invention will be described in detail below with reference to the drawings and specific embodiments.

[0025] The structure of composite material speed drilling bridge plug, such as Figure 1-3 As shown, the shaft 1 has a length of 622.5mm, an outer diameter of 75mm, and an inner diameter of 25mm. An end shaft 8 is provided on the outer surface of the bottom end of the shaft 1, and the outer diameter of the end shaft 8 is 112mm. A plug 9 is installed in the pin 13 at the top of the shaft 1. The plug 9 and the shaft 1 are sealed by a sealing ring 10, the size of the sealing ring 10 is 25×2.65mm; the first slip seat 4 and the second The slip seat 6 is fixed on the shaft 1 by four set screws 11, the sealing ring 12 is installed between the first slip seat 4 and the second slip seat 6, and the sealing ring 12 is connected to the first slip seat 4 , The second slip seat 6 is provided with a transition shoe 5, the first slip seat 4 is connected to one end of the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistant | aaaaa | aaaaa |

| Withstand voltage | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com