Drying kiln for non-dismantling heat insulating template

A thermal insulation formwork and drying kiln technology, applied in the field of drying kiln, can solve the problems of complex structure of drying device, low work efficiency, large environmental pollution, etc., and achieve good drying effect, fast flow rate and small contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

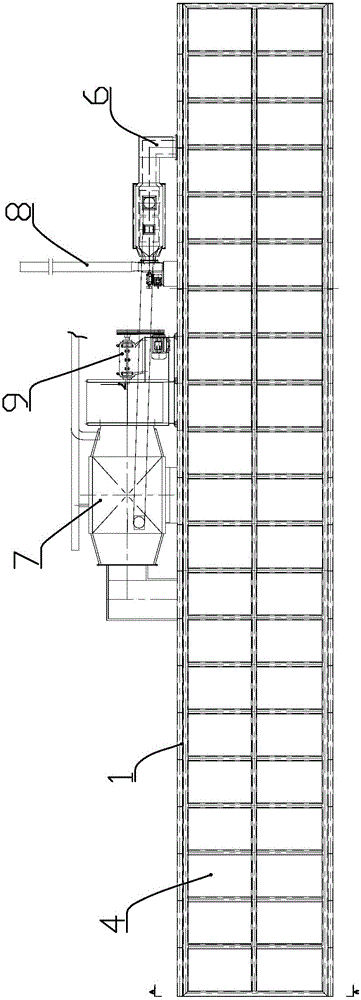

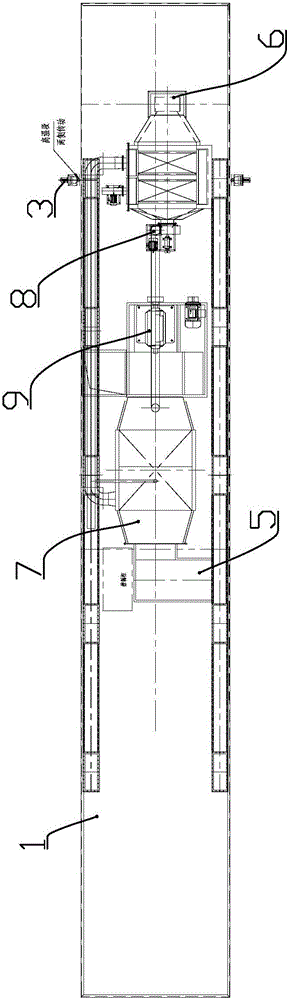

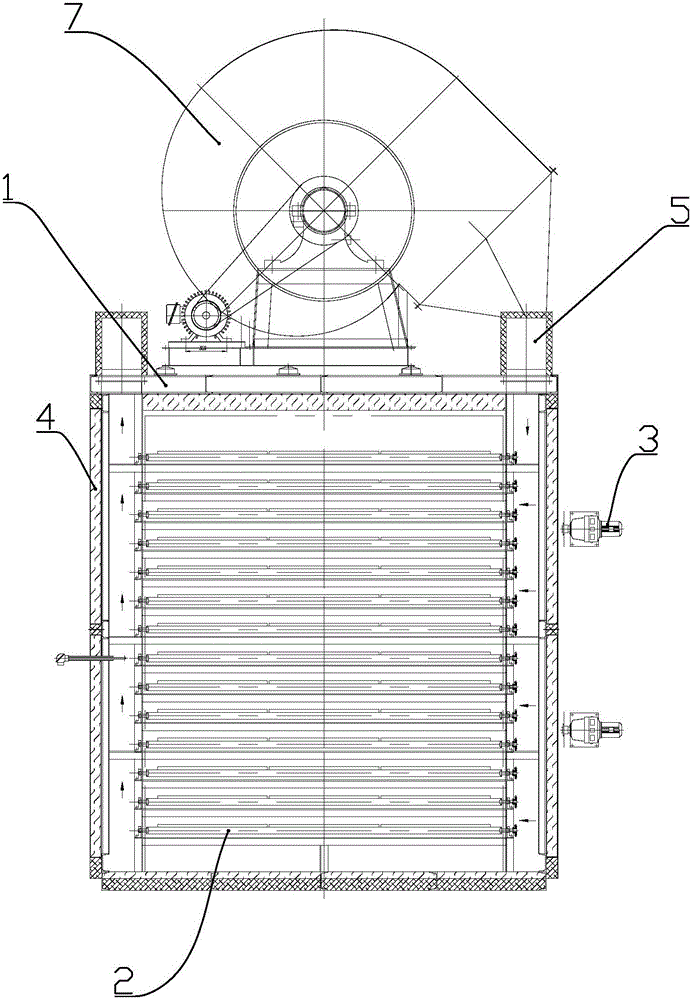

[0020] Such as figure 1 , 2 . As shown in 3, a drying kiln without dismantling the heat preservation formwork includes a kiln body 1 with openings at both ends, and at least two layers of supporting rollers 2 are installed in the kiln body 1, and the supporting rollers 2 are installed horizontally, And perpendicular to the kiln body 1, equidistantly installed from one end of the kiln body 1 to the other end of the kiln body 1, the distance between the adjacent upper and lower rollers 2 is greater than the thickness of the non-removable thermal insulation formwork, and the rollers 2 Driven by a motor 3, a hot gas inlet 5 and a waste gas outlet 6 are provided on the top of the kiln body 1, and a heater 7 is connected to the hot gas inlet 5, and a circulating fan 9 is installed on the heater 7. The exhaust gas outlet 6 is connected with a chimney 8 .

[0021] The dismantling-free thermal insulation formwork is conveyed from one end of the kiln body 1 to the other end through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com