Detection method for solid content of MUF resin

A solid content and detection method technology, which is applied in the direction of measuring devices, phase influence characteristic measurement, and material analysis through optical means, can solve the problems of long time consumption and inability to quickly reflect the resin solid content index, so as to save production resources and solve Effects of detection lag and improvement of detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

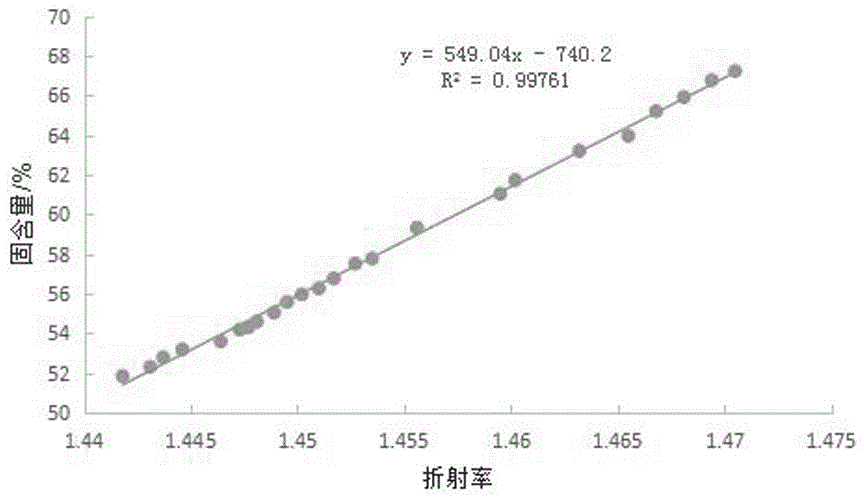

[0028] The detection method of MUF resin solid content comprises the steps:

[0029] A. Put the MUF resin sample DY-E2-250M to be tested in a test tube numbered 1, and keep the temperature at 25°C to balance;

[0030] B. The refractive index of the sample was measured with an Abbe refractometer, three groups were measured in parallel, and the average value was 1.4410, and the light source was white light;

[0031] C. Find the X value on the standard working curve, and read the corresponding Y value, which is the solid content of MUF resin is 50.96%.

[0032] Correspondingly, using the drying method specified in GB / T 14074-2006 Wood Adhesives and Resin Test Methods,

[0033] The solid content of this sample was measured to be 50.67%.

Embodiment 2

[0035] The detection method of MUF resin solid content comprises the steps:

[0036] A. Put the MUF resin sample DY-E1-400M to be tested in the test tube numbered 2, and keep the temperature at 25°C to balance;

[0037] B. The refractive index of the sample was measured with an Abbe refractometer, three groups were measured in parallel, and the average value was 1.4414, and the light source was white light;

[0038] C. Find the X value on the standard working curve, and read the corresponding Y value, which is the solid content of MUF resin is 51.17%. Correspondingly, using the drying method specified in GB / T 14074-2006 Wood Adhesives and Resin Test Methods,

[0039] The solid content of this sample was measured to be 51.61%.

Embodiment 3

[0041] The detection method of MUF resin solid content comprises the steps:

[0042] A. Put the MUF resin sample DY-E1-200M to be tested in the test tube numbered 3, and keep the temperature at 25°C to balance;

[0043] B. The refractive index of the sample was measured with an Abbe refractometer, three groups were measured in parallel, and the average value was 1.4448, and the light source was white light;

[0044] C. Find the X value on the standard working curve, and read the corresponding Y value, which is the solid content of MUF resin is 53.03%.

[0045] Correspondingly, using the drying method specified in GB / T 14074-2006 Wood Adhesives and Resin Test Methods, the solid content of this sample was measured to be 52.62%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com