Reversible belt tightener

A technology of seat belt tensioner and seat belt, which is applied to belt tensioners, seat belts in vehicles, belts/chains/gears, etc., can solve the problems that the layout form cannot be freely selected, and noise can no longer be accepted, so as to achieve simplification. The effect of structure, loss reduction, and manufacturing cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

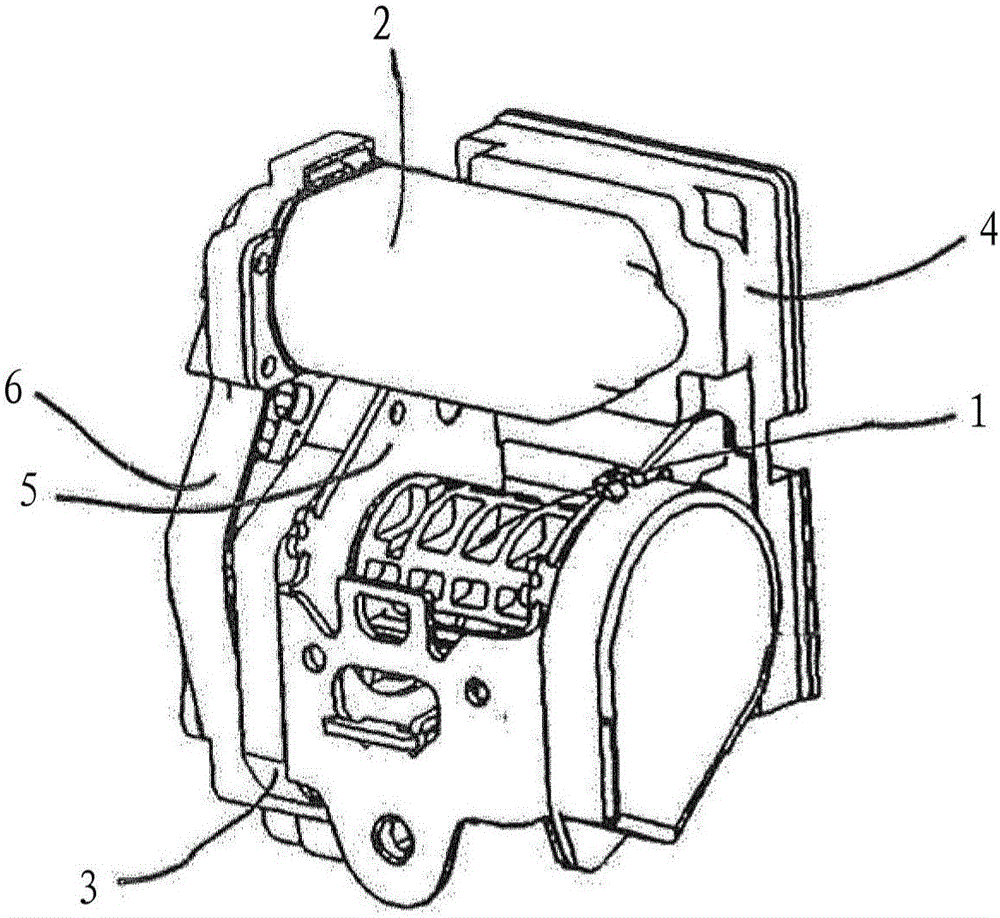

[0019] in figure 1 with figure 2 Shown therein is a reversible safety tensioner known from WO 2003 / 099619 A2, which has a belt shaft 1 and a motor 2 that drives the belt shaft 1 in the winding direction during reversible tightening. An electronic control unit 4 (ECU) is provided on one side of the reversible seat belt tensioner, and the control unit controls the motor 2. Furthermore, a transmission housing 3 with a corresponding cover plate 6 is provided on the end side of the belt retractor housing.

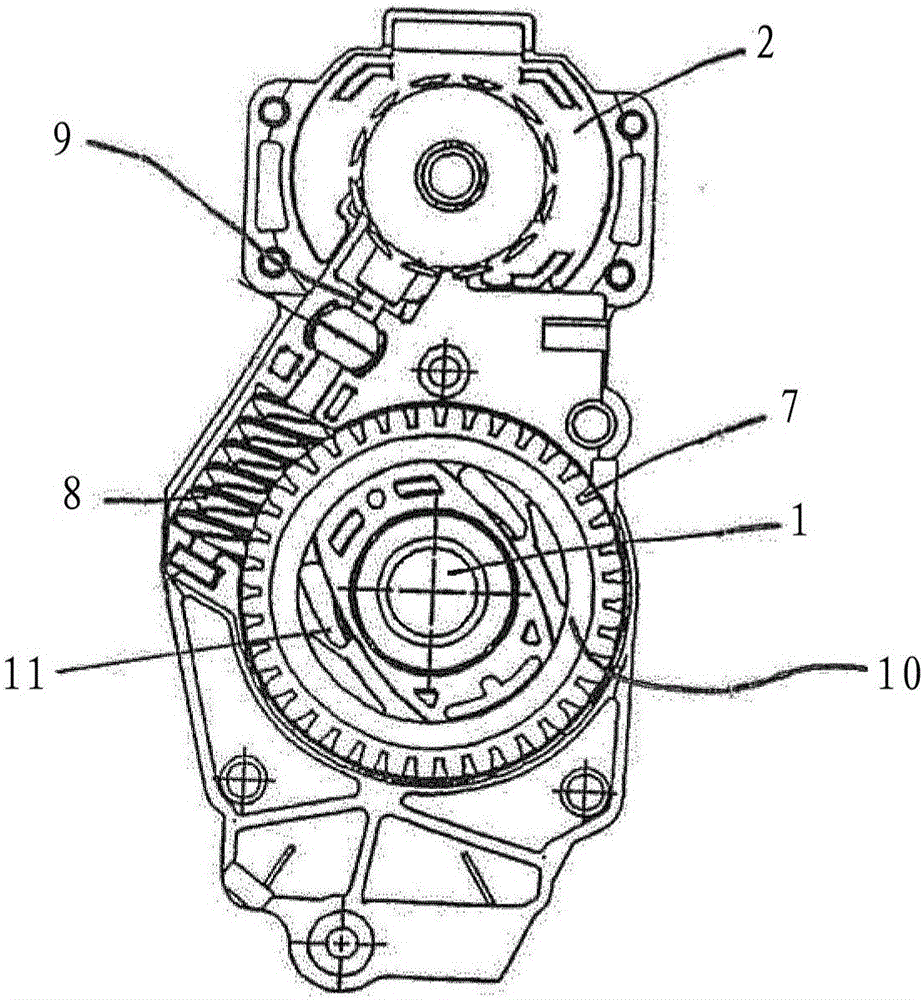

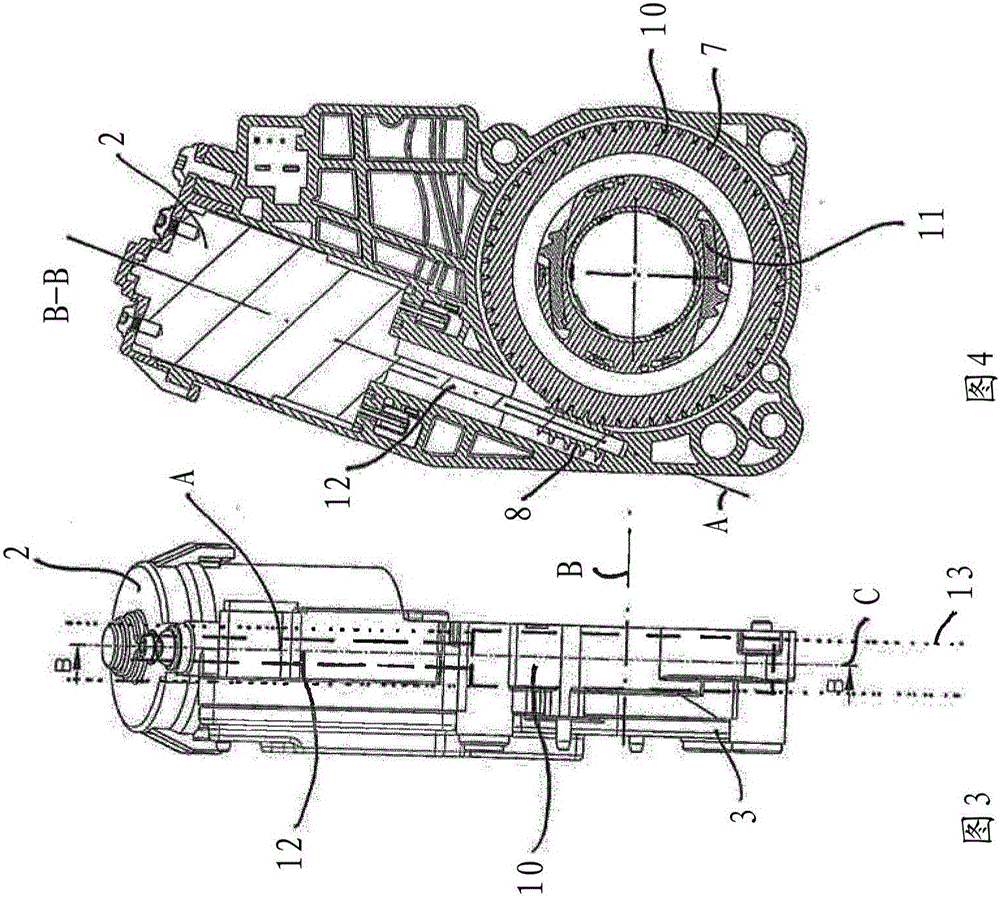

[0020] in figure 2 The reversible seat belt tensioner is shown from the side of the drive device, but there is no cover plate 6. A transmission shaft 9 can be seen between the belt shaft 1 and the motor 2, and the transmission shaft is meshed into the teeth 7 of the drive gear 10 via a worm 8. The connection between the motor 2 and the transmission shaft 9 is here realized by a crown gear transmission, not shown. The driving gear 10 is also connected to the belt shaft 1 via a c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap