Kitchen waste residue and liquid separator

A kitchen waste and separator technology, which is applied in the directions of liquid separation, filtration separation, separation methods, etc., can solve the problems of slow filtration, pollute the environment, and do not meet environmental protection regulations, and achieve the effect of separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

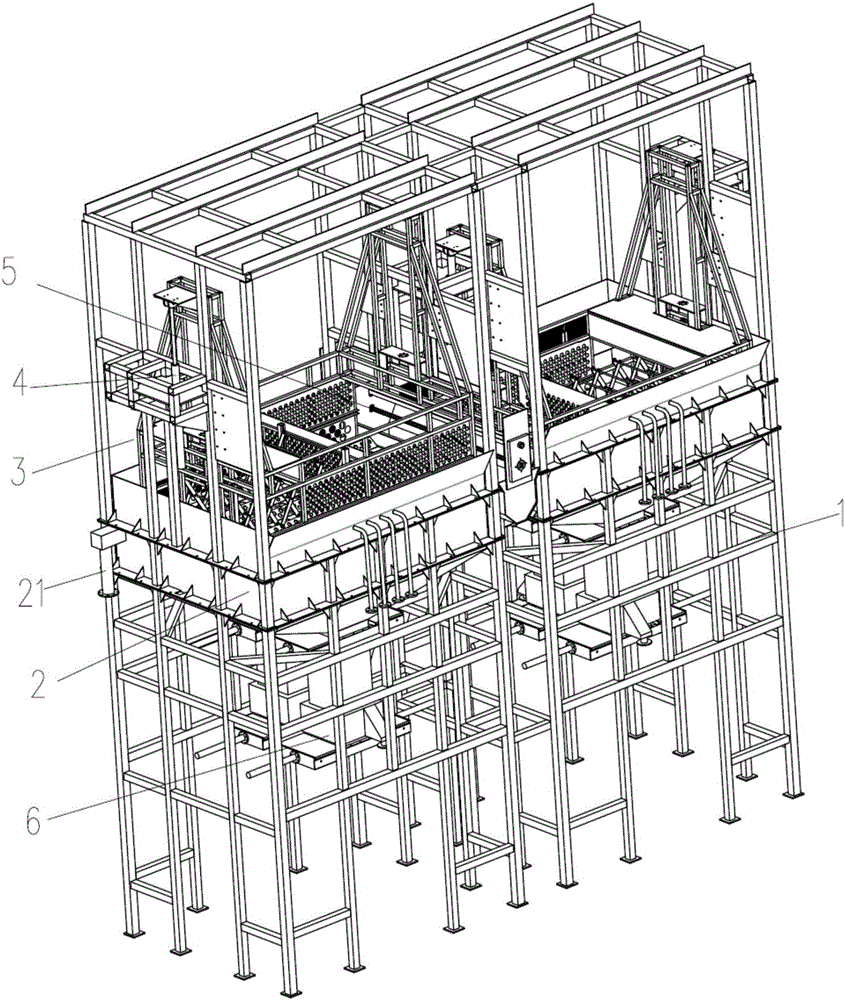

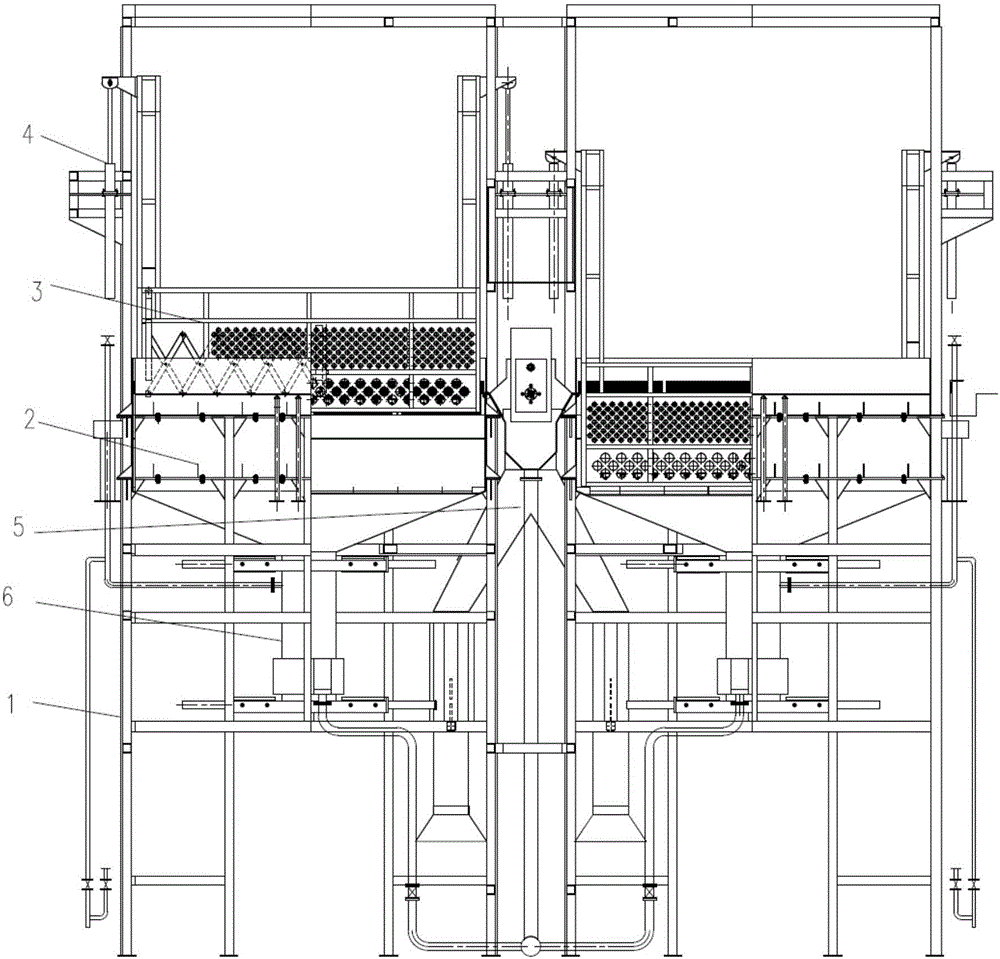

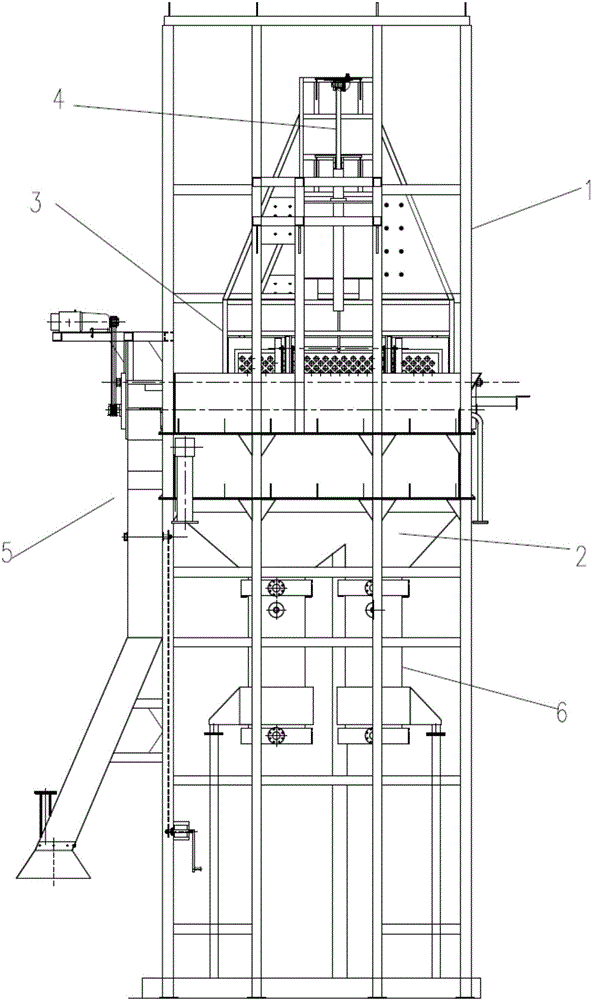

[0031] like Figure 1 to Figure 3 As shown, the present invention proposes a kitchen waste slag-liquid separator, comprising: a frame 1; a steel pool body 2 installed on the frame 1 to store warm water; a grate device is arranged above the steel pool body 2 3, to store food waste solids; on the frame 1, a lifting mechanism 4 is arranged, and the lifting mechanism 4 is connected with the trough device 3, so that the trough device 3 can be immersed in or out of warm water back and forth; on the frame 1 There is a draining and scraping tank 5 next to the draining device 3. When the lifting mechanism 4 lifts the draining device 3 to a position flush with the draining and scraping tank 5, the draining device 3 outputs food to the draining and scraping tank 5. Kitchen waste solids, draining and scraping slag tank 5 is used to discharge the food waste solids into the transport barrel; a slag-liquid separator 6 is arranged at the bottom of the steel pool body 2 to separate and dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com