Forging method of hanger

A technology of hanger and initial forging temperature, applied in metal processing equipment and other directions, can solve the problems of complex hanger forging method, etc., and achieve the effect of high strength and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] A forging method of a hanger, comprising the steps of:

[0027] 1) Material selection and blanking, removing the head and tail of the blank, and then blanking;

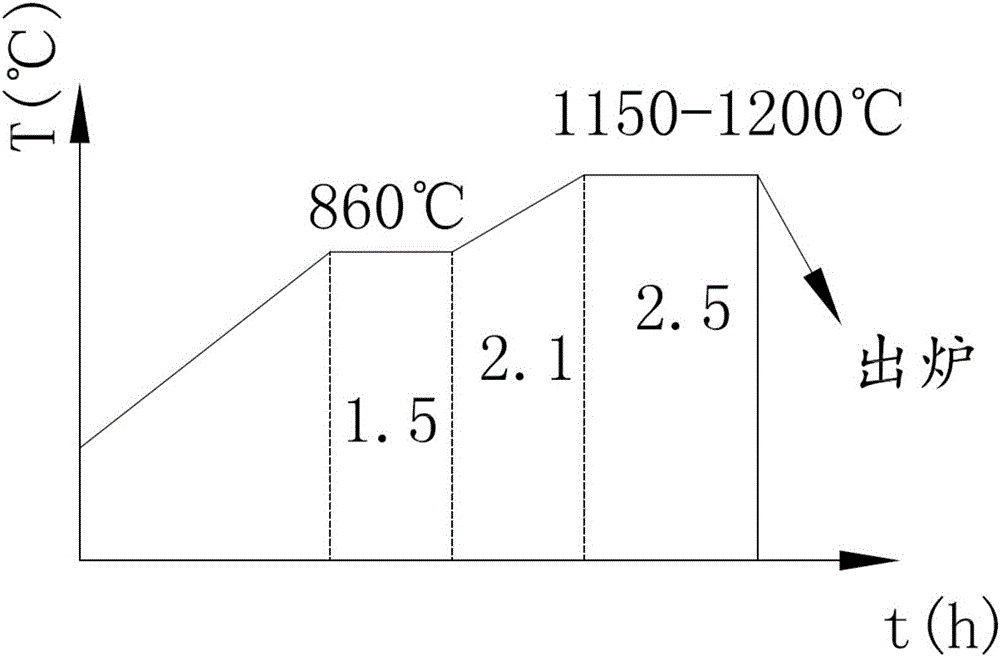

[0028] 2) Heating, provide a furnace, the temperature of the furnace is not higher than 1000 ° C, when the furnace temperature reaches the initial forging temperature, it needs to be kept for two and a half hours, and the material sections enter the furnace in order, first in first out;

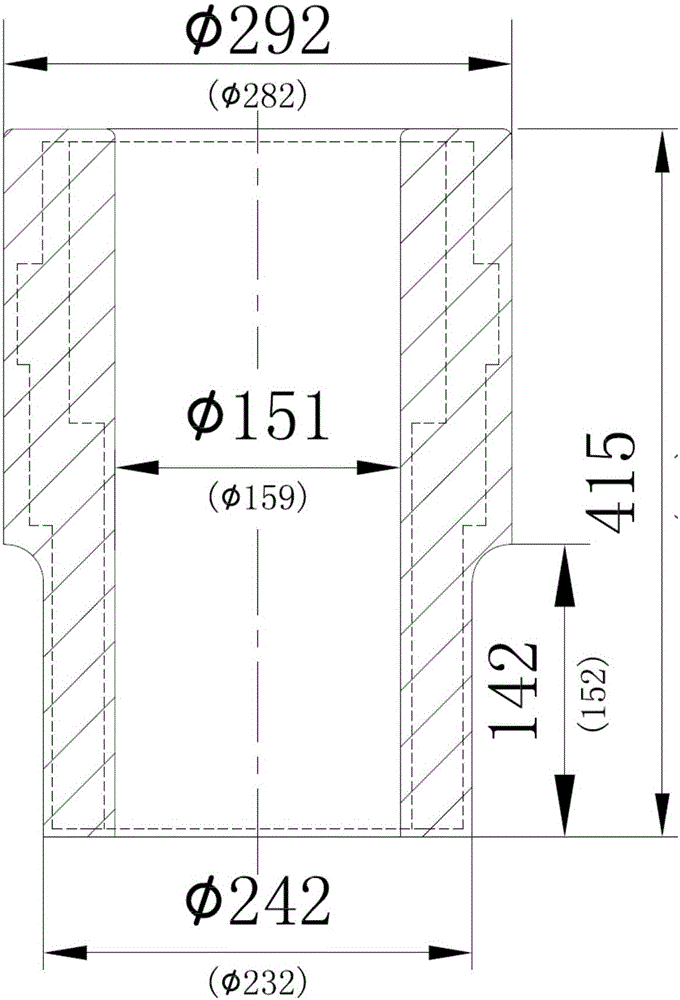

[0029] 3) Forging and extrusion, the stroke of the main pressure head of the slider is set, the distance between the main pressure heads is adjusted after the blank is loaded into the mold, and the distance between the main pressure heads is adjusted, and the stroke of the main pressure head reaches the set value.

[0030] 4) Punch out, move the upper slide to the punching station, adjust the distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com