Industrial rolling shaft workpiece cutting device

A technology of cutting equipment and rollers, which is applied in the field of industrial automation cutting equipment, can solve the problems of easy rollover cutting operation risk, large vibration amplitude, and high labor intensity of manual operation, etc., so as to avoid cutting operation risks and reduce vibration amplitude , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be described below in conjunction with specific embodiments.

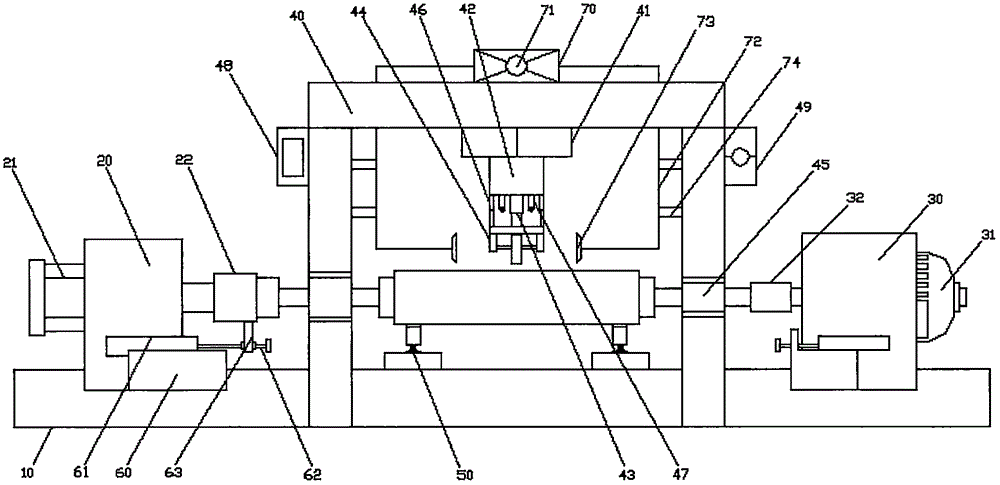

[0021] Such as figure 1 and figure 2 As shown, it is a structural schematic diagram of an industrial roller workpiece cutting equipment according to the present invention.

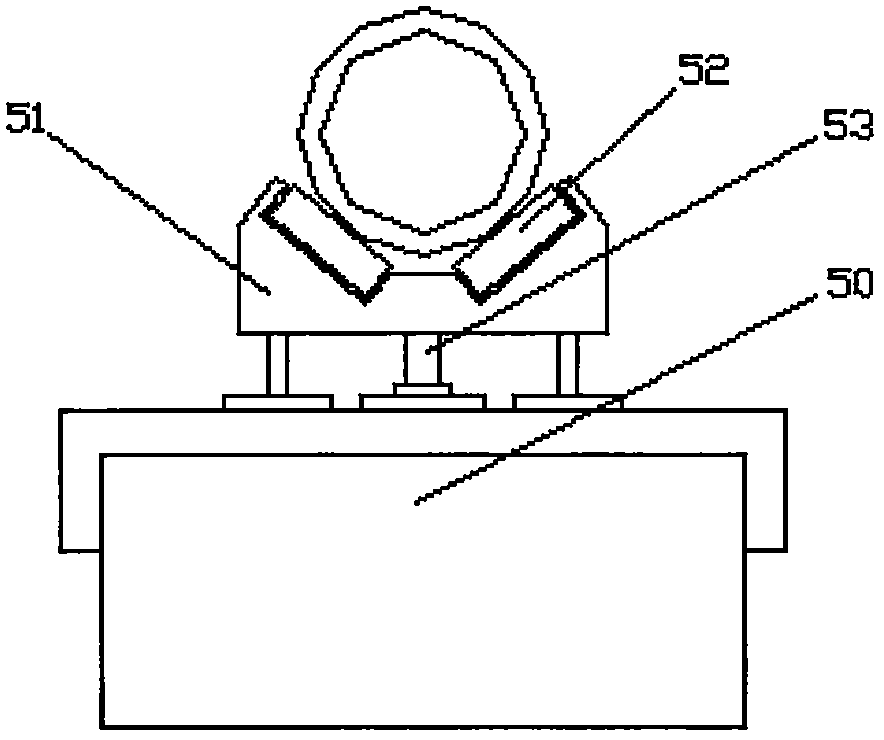

[0022] An industrial roller workpiece cutting device according to the present invention includes: a base 10, and a clamping and rotating mechanism for clamping and rotating the roller workpiece is provided at both ends of the base 10; the clamping and rotating mechanism includes first clamps arranged opposite to each other The holding seat 20 and the second holding seat 30, the first holding seat 20 is provided with a clamping oil cylinder 21 coaxial with the roller workpiece, and the cylinder barrel of the holding oil cylinder 21 is fixed on the first holding seat 20 On the top, the free end of the piston rod of the clamping oil cylinder 21 faces the second clamping seat 30 and is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com