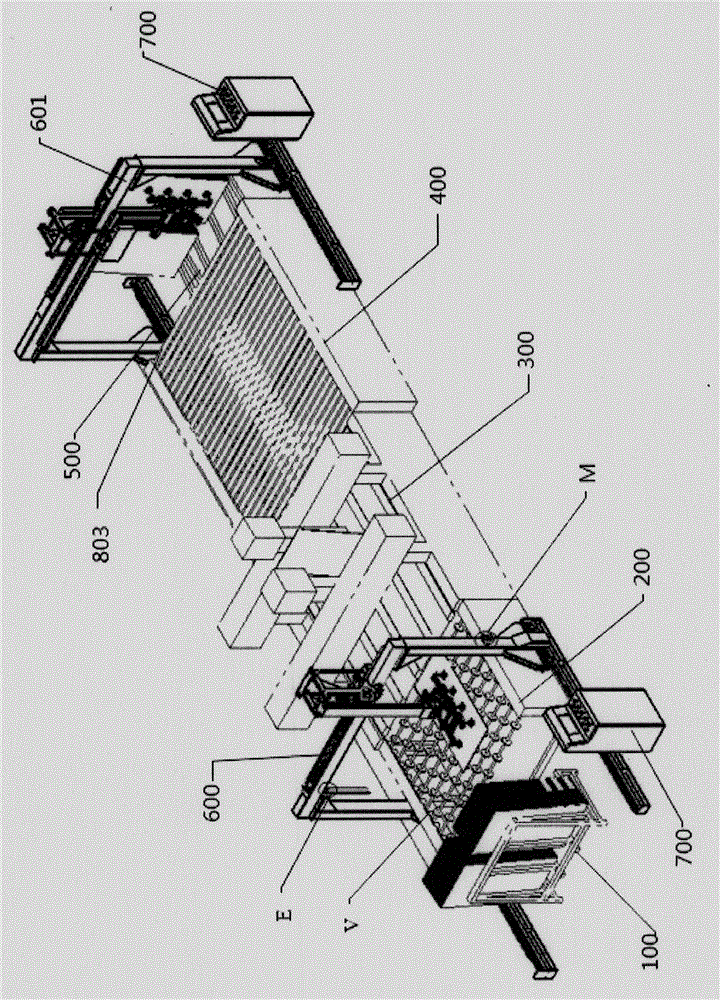

Automatic feeding and blanking system for glass milling machine

A technology of automatic loading and unloading, edge grinding machine, applied in machine tools, grinding frames, grinding machines and other directions suitable for grinding workpiece edges, can solve the problems of inability to perform angle compensation, large floor space, single action, etc. Flexible and convenient operation, small footprint and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

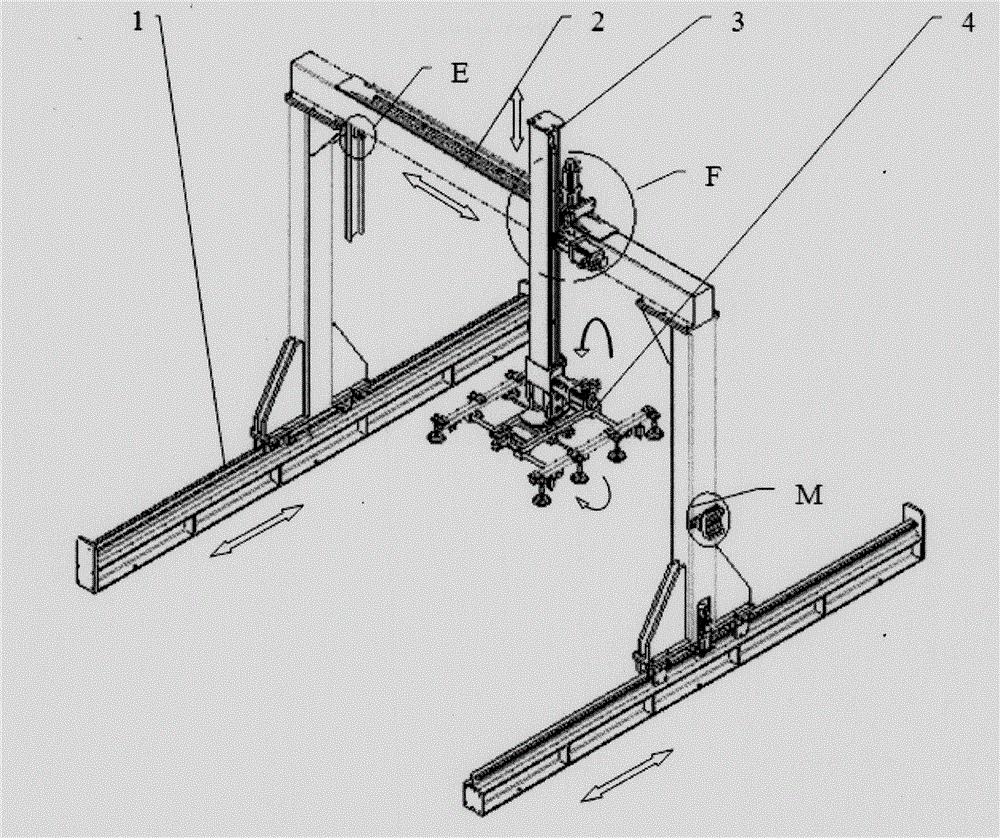

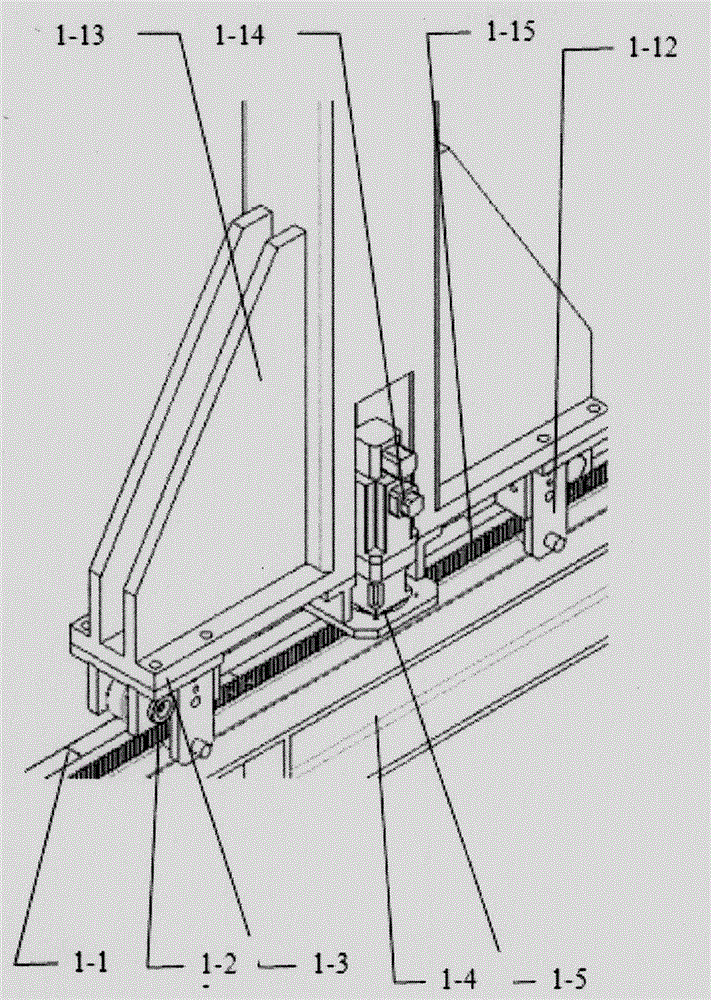

[0062] Specific embodiment 1: as Figure 11-12 As shown, when the upper and lower sheets of glass are in a single row: a processing technology suitable for the automatic loading and unloading system of the glass edging machine, the technical solution is: 1. Input the glass thickness to the control box 700; Linkage automatically adjusts before approaching the glass shelf I 500. At this time, the angle of the glass grabbing frame 4 is consistent with the glass surface. According to the size and placement of the glass, the center position of the first glass is manually corrected. At this time, the coordinate information is sent to the control box. 700; then the X-axis assembly 1 in the grabbing mechanism 600 continues to move closer to the glass, the travel switch 4-2 on the lower side of the glass grabbing frame 600, the electromagnetic valve set is opened, the vacuum generator set is connected, and the vacuum chuck 4-4 sucks Hold the glass, and adjust the working area of the ...

specific Embodiment 2

[0067] Specific embodiment 2: when dealing with the situation of double-row stacking, such as Figure 13shown. The technological process adopted is: input the glass thickness and double-row glass spacing into the control box 700; the grasping mechanism 600 automatically adjusts the four-axis linkage before approaching the glass shelf I500, manually aligns the center position of the first glass in the first row, and other actions Carry out the steps of single-row loading and unloading in Example 1; after the first row is transported by the grabbing mechanism 600, it automatically returns to the initial position, reads the distance between the double-row glass in the control box 700 and automatically moves to the center position of the second row of glass , to carry out the automatic moving action; after the stacking and grabbing mechanism 601 stacks the first row of glasses, it reads the distance between the double rows of glasses and continues to stack the second row of glasse...

specific Embodiment 3

[0068] Specific embodiment 3: as Figure 10 As shown, when the upper and lower sheets are placed in different sizes of glass, the edger 300 has technological requirements, so the length direction of the glass is in contact with the side pulley 301 if the glass width is less than 850mm; in order to meet the technological requirements of the edger, Four partition control keys are set in the control box 700, and different vacuum suction cups 4-4 start and stop modes are selected according to the specifications of the glass; the glass grabbing frame needs to be rotated and driven 490 degrees to facilitate use; therefore, this process requires five-axis linkage and stacking The grabbing mechanism 601 is also rotated 90 degrees before stacking; the rest of the actions are the same as the process of single-row loading and unloading in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com