Material charging box for bonding of neodymium iron boron magnet

A neodymium-iron-boron and charging box technology is applied to the material box for NdFeB magnet bonding and the field of neodymium-iron-boron magnets, which can solve the problem that the sealing effect of the material box is not very good, affecting the performance of the neodymium-iron-boron magnet, etc. problems, to achieve the effect of preventing gaps, improving performance, and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

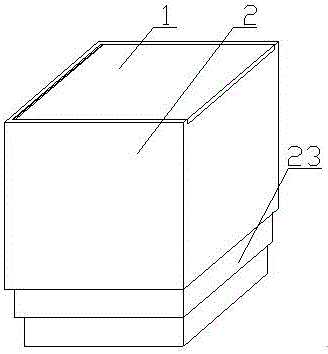

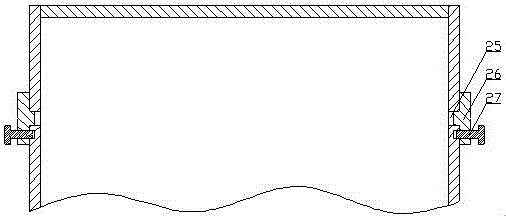

[0032] A charging box for bonding NdFeB magnets, comprising a material box body 2, a connecting shaft 3, and a material box cover 1, the side wall of the material box body 2 is provided with a communication channel with the inside of the material box body 2 Stoma 25, described air hole 25 is equipped with plug 26, is connected with guide rod 27 on the described plug 26, and described guide rod 27 passes through the guide hole on the plug 26 and meets the side of material box body 2 Wall connection; the top of the connecting side wall of the material box body 2 is provided with a mounting groove 21, and the connecting end of the material box cover 1 is located in the mounting groove 21 of the material box body 2, and the cylindrical surface of the material box cover 1 17 fits with the arc surface 22 of the material box body 2; a partition plate 15 is arranged in the described material box cover 1, and the inner cavity of the material box cover 1 is divided into a left chamber 16...

Embodiment 2

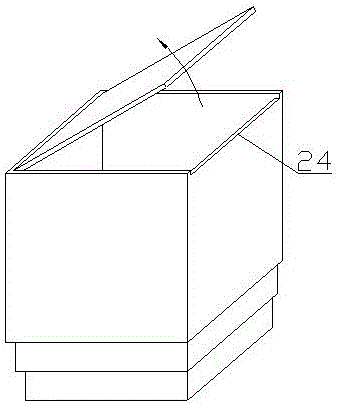

[0034] On the basis of Embodiment 1, the top surface of the connecting opposite surface 24 of the magazine body 2 is lower than the remaining sides of the magazine body 2, and the top surfaces of the remaining sides of the magazine body 2 are even, and the magazine The height difference between the top surface of the connecting opposite surface 24 of the body 2 and the top surface of the remaining sides of the cartridge body 2 is equal to the thickness of the cartridge cover 1 .

Embodiment 3

[0036] On the basis of the first or second embodiment, at least two steps 23 are arranged at the bottom of the cartridge body 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com