Accurate weighing device for raw material of brake tile

A technology for weighing devices and raw materials, applied in conveyor control devices, loading/unloading, transportation and packaging, etc., can solve the problems of low investment costs, high labor costs, and low precision, and achieve simple equipment structure and improved The effects of labor efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

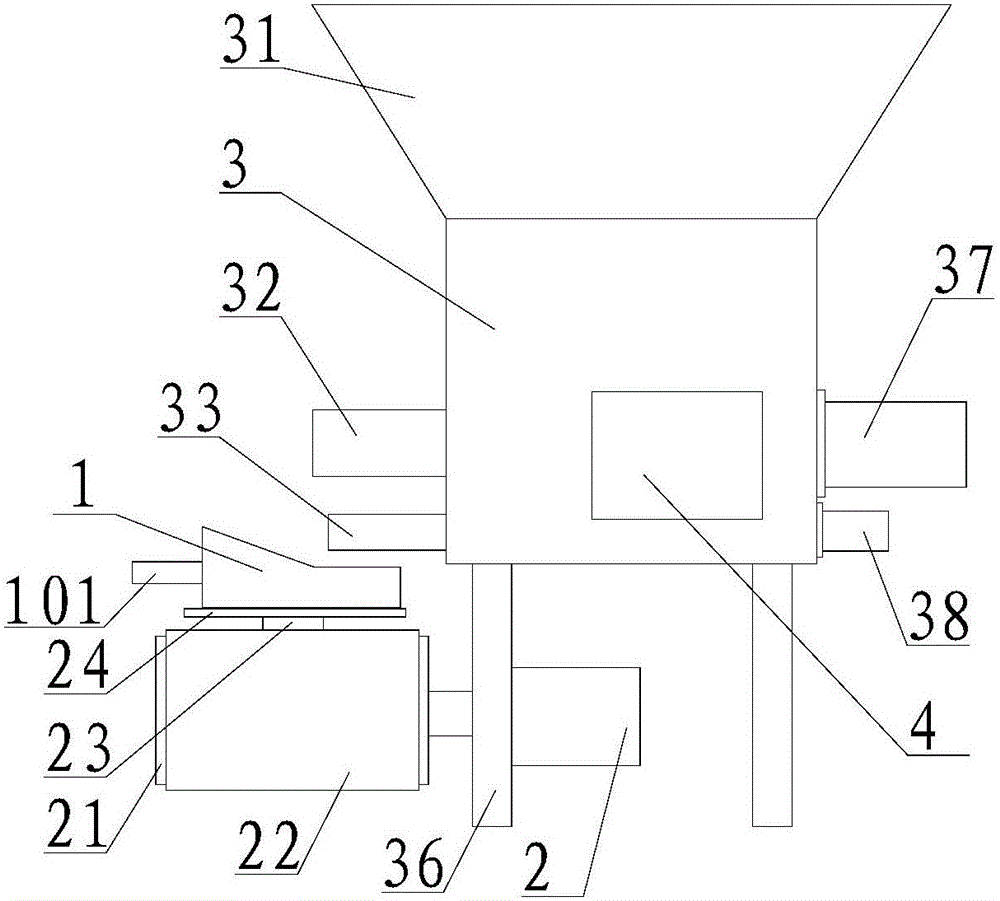

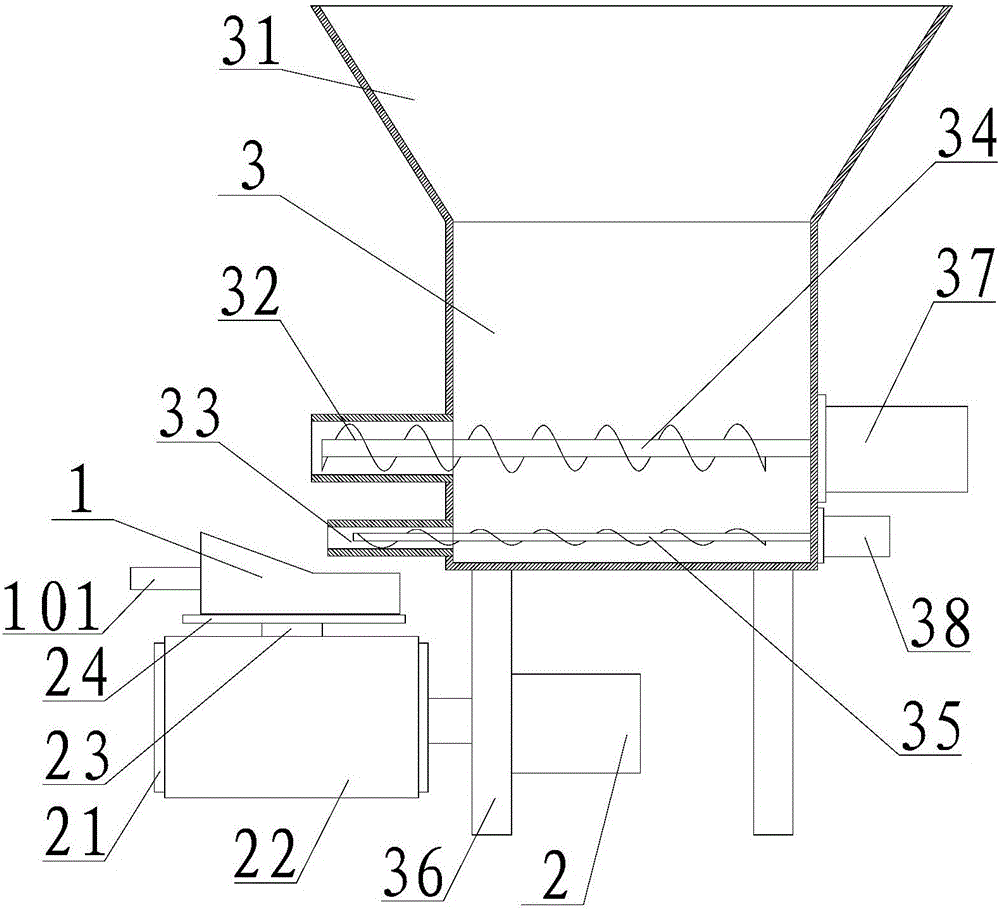

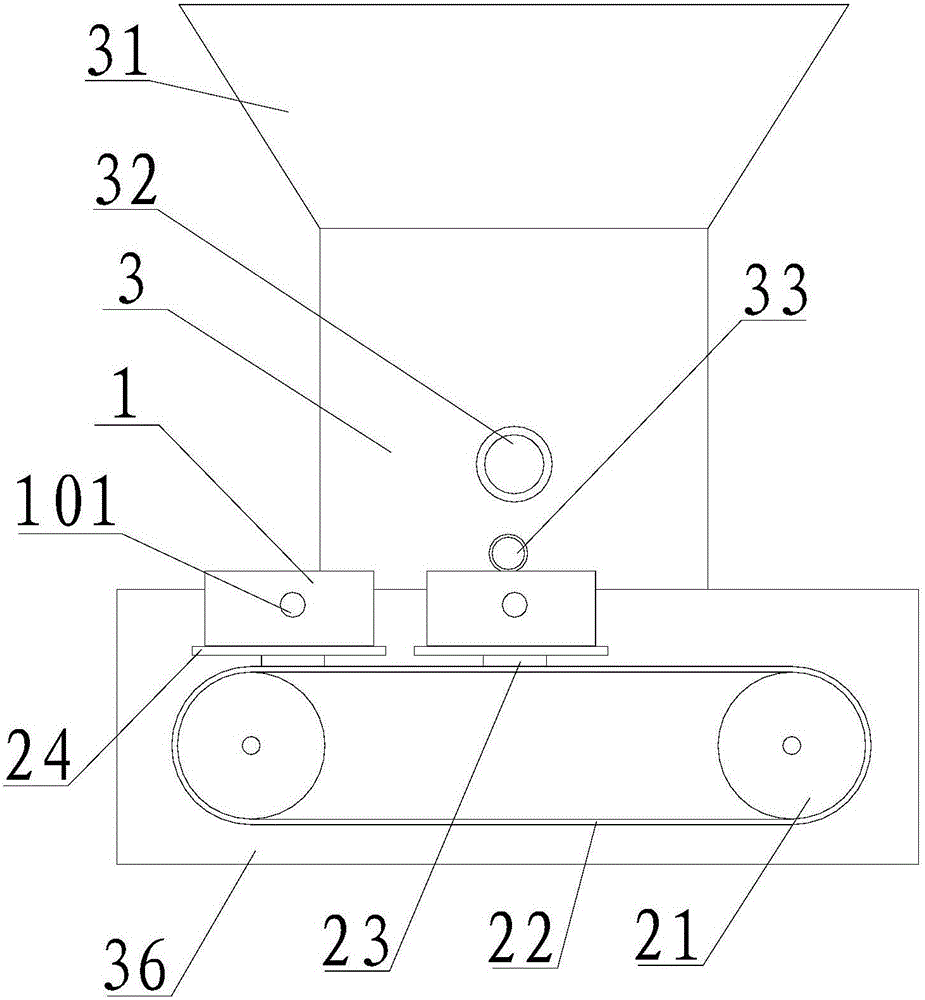

[0018] refer to figure 1 , figure 2 and image 3 , an accurate weighing device for brake tile raw materials according to the present invention, comprising a hopper 1, a conveying roller motor 2, a conveying roller 21, a storage tank 3 and a control unit 4, the upper part of the storage tank 3 is provided with a feeding port 31, The left side of the storage barrel 3 is provided with a main discharge barrel 32 and a secondary discharge barrel 33, and the right side of the storage barrel 3 is provided with a main feeding motor 37 and an auxiliary feeding motor 38, and the main feeding motor 37 is connected with a main feeding motor. The screw rod 34, the auxiliary screw rod 35 is connected to the auxiliary feeding motor 38, the control part 4 is installed on the material storage tank 3, and the lower part of the material storage tank 3 is provided with a fixed plate 36, and a transmission roller is installed on the fixed plate 36 Motor 2, the transmission roller motor 2 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com