Method for controlling corn oil color reversion

A corn oil and corn germ technology, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of oil color darkening, color reversion, etc., achieve low color and effect of inhibiting enzymatic oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

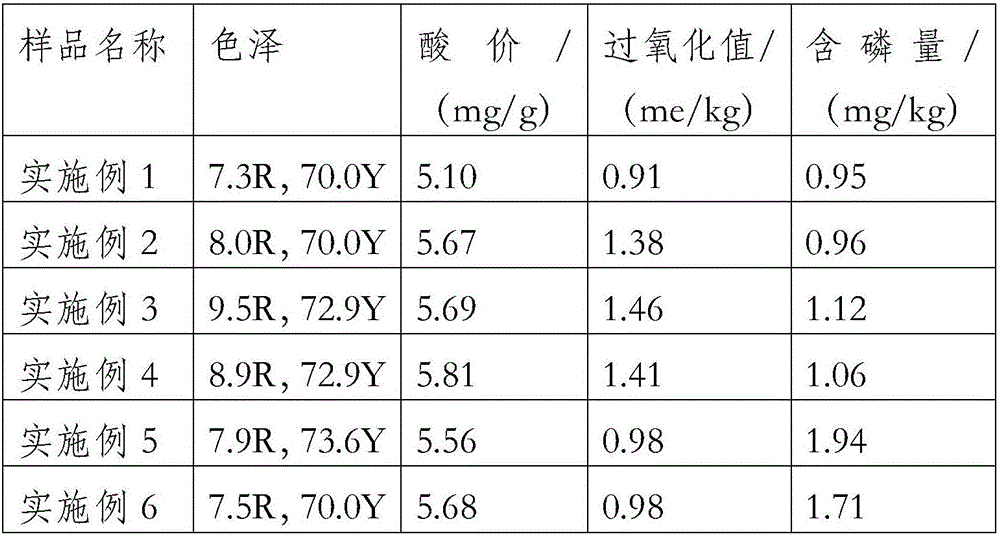

Embodiment 1

[0021] Take 0.5kg of corn germ and grind it in a pulverizer, pass through a 50-mesh sieve after crushing, immediately put the germ particles in a container, spread a layer evenly to make the powder evenly distributed, and then put it into a 0.1kpa high-pressure sterilization pot , set the temperature at 110°C, and set the time for 5 minutes. After the enzyme is inactivated, take out the germ granules, cool to 60°C at room temperature, and put them in a 60°C oven to reduce the moisture to 9% by mass.

[0022] Extract the crude oil from the germ granules obtained in Example 1, and find that the crude oil has the lightest color, which is 7.3R, 70.0Y, and then refine the crude oil, store the resulting refined oil, and carry out storage experiments. The color change of the oil after the sample is stored at 20±5°C and normal indoor light for 6 months, the change of Lovibond red value |ΔR|<0.3, it can be considered that the above enzyme inactivation method is effective and inhibits th...

Embodiment 2

[0024] Take 0.5kg of corn germ and grind it in a grinder, pass through a 50-mesh sieve after crushing, immediately put the germ particles in a container, spread a layer evenly to make the powder evenly distributed, and then put it into a 0.2kpa high-pressure sterilization pot , set the temperature at 120°C for 5 minutes, after the enzyme inactivation is completed, take out the germ granules, cool them to about 60°C at room temperature, and put them in a 60°C oven to reduce the moisture to 10%. Crude oil was extracted from the germ granules obtained in Example 2, and the color of the crude oil was found to be 8.0R, 70.0Y.

Embodiment 3

[0026] Take 0.5kg of corn germ and grind it in a pulverizer, pass through a 50-mesh sieve after crushing, immediately put the germ particles in a container, spread a layer evenly to make the powder evenly distributed, and then put it into a 0.1kpa high-pressure sterilization pot , set the temperature at 110°C, and set the time for 1min. After the enzyme is inactivated, take out the germ granules, cool them to about 60°C at room temperature, and put them in a 60°C oven to reduce the moisture to 12%. The crude oil was extracted from the germ granules obtained in Example 3, and it was found that the crude oil had the darkest color, 9.5R, 72.9Y.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Color | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com