Production method of roasted green tea

A production method and green tea technology, which are applied in the production field of fried green tea, can solve the problems of poor color and inability to fully stimulate the aroma of green tea, and achieve the effects of facilitating rolling, promoting the formation of aroma, and inhibiting enzymatic oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

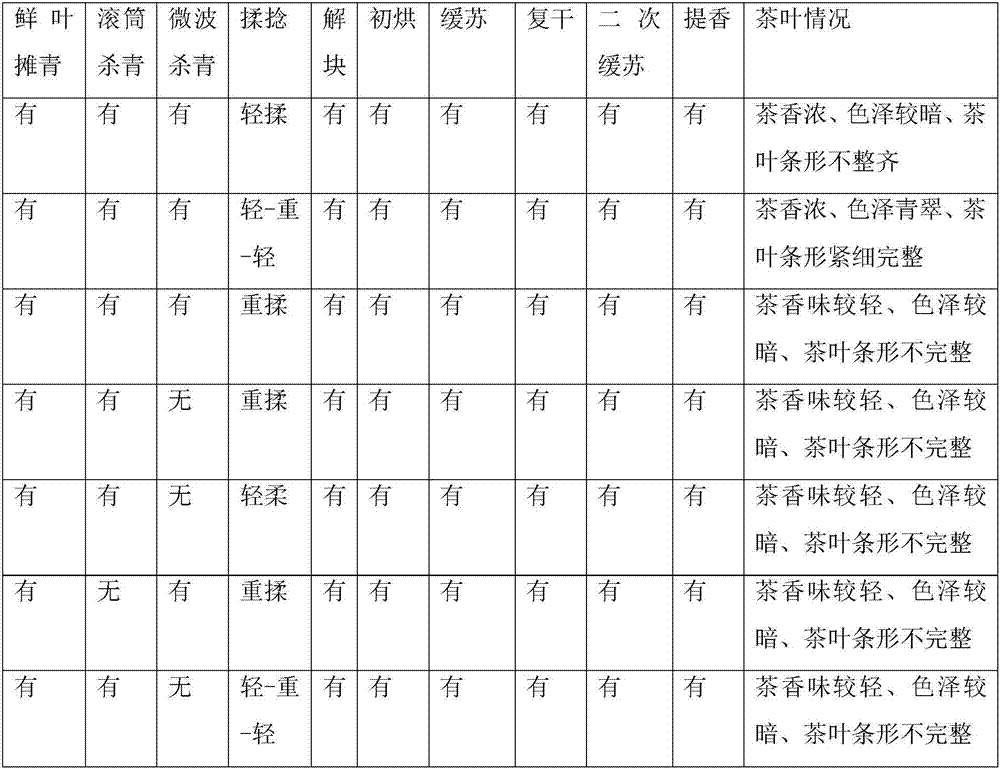

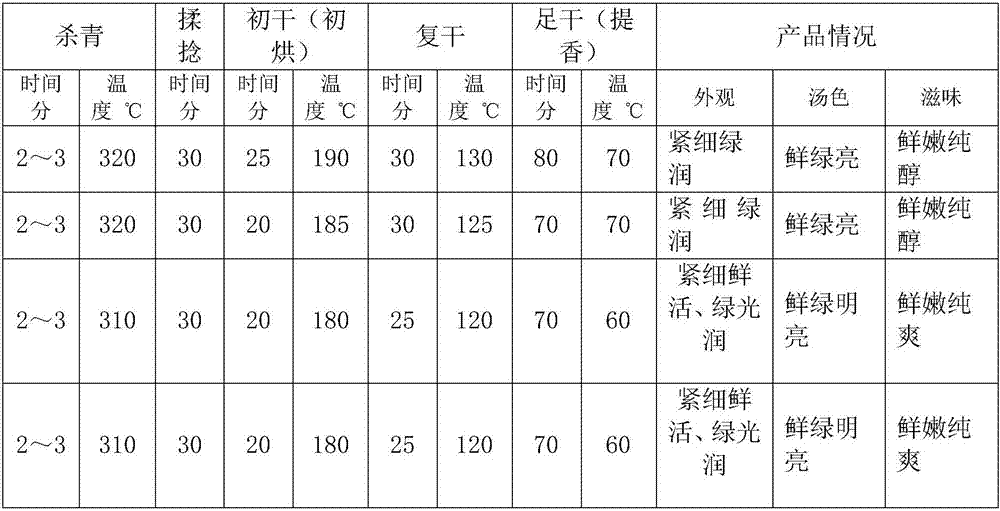

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0034] A production method of fried green tea, comprising the following steps:

[0035] Greening of fresh leaves: spread fresh tea leaves in a cool and ventilated environment; in the step of spreading green leaves, the thickness of fresh leaves should not exceed 5-10 cm, and the time for spreading green leaves should be 4-6 hours. The fresh leaves should be placed in a cool, ventilated, clean room free from direct sunlight. To use the greening equipment, the air supply system should be turned on during the cooling process to keep the fresh leaves fluffy. 4-6 hours can make the leaf color darken, the leaf quality is wilted,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com