Steel sheet for hot pressing

A technology for hot-pressed steel plates and steel plates, which is applied in the field of hot-pressed steel plates, can solve problems such as poor appearance, damage to molds, and decreased coating adhesion, and achieve excellent coating adhesion, excellent pitting resistance, and Excellent oxidation resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

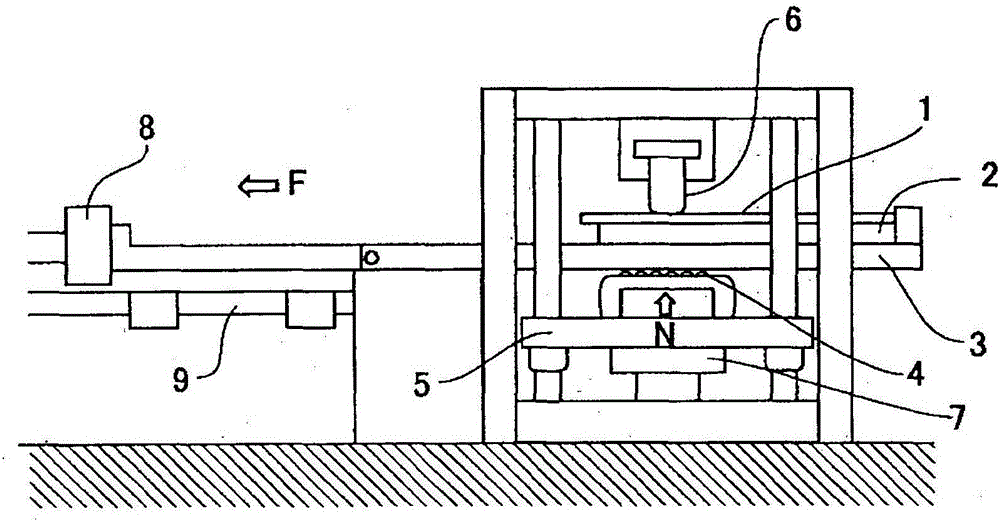

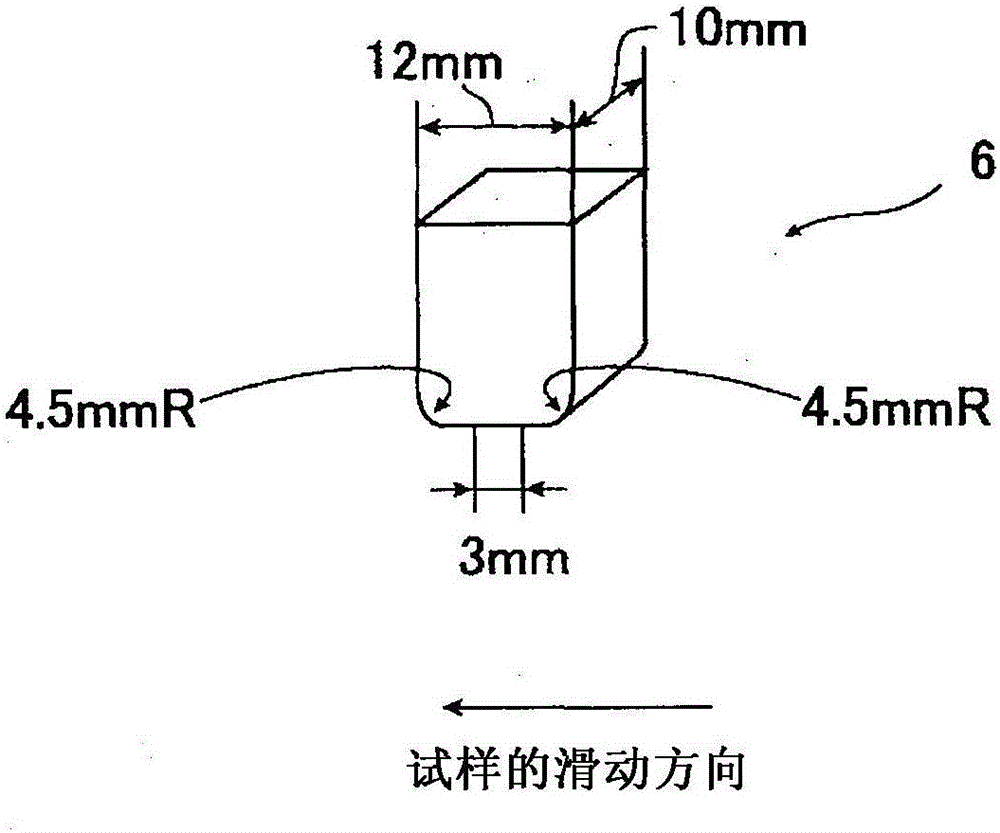

Method used

Image

Examples

Embodiment approach A

[0041] A-1 steel plate for hot pressing

[0042] A-1-1) Coating

[0043] In Embodiment A, in order to suppress the formation of scale and ZnO during hot pressing, a plating layer containing 10 to 25% by mass of Ni and the balance of Zn and unavoidable impurities is provided on the surface of the steel sheet. By making the Ni content of the plating layer 10 to 25% by mass, it is possible to form a 2 Zn 11 、NiZn 3 、Ni 5 Zn 21 Any one of the crystal structures has a melting point as high as the γ phase of 881°C, so the generation reaction of scale and ZnO during heating can be suppressed to a minimum. In addition, since Zn-Fe metal oxides are not formed when heated, the generation of scale accompanying cracks is also suppressed. In addition, since the plating layer remains in the form of the γ phase after hot pressing, excellent corrosion resistance is exhibited due to the sacrificial anticorrosion effect of Zn. It should be noted that the formation of the γ phase with a N...

Embodiment A

[0097] As the base steel sheet, a steel sheet containing C: 0.23%, Si: 0.25%, Mn: 1.2%, P: 0.01%, S: 0.01%, Al: 0.03%, N: 0.005%, and Cr: 0.2% was used in mass %. , Ti: 0.02%, B: 0.0022%, Sb: 0.008%, and the balance is composed of Fe and unavoidable impurities, and Ac 3 A cold-rolled steel sheet with a transformation point of 820°C and a thickness of 1.6 mm. On the surface of the cold-rolled steel sheet, in a plating solution containing 200g / L nickel sulfate hexahydrate and 10-100g / L zinc sulfate heptahydrate with a pH of 1.5 and a temperature of 50°C, the current density is 5-100A / dm 2 Change between, implement electroplating treatment, form the coating layer of Ni content (remainder is Zn and unavoidable impurity) and adhesion amount and η phase content shown in table 1, 2. In addition, except for some cases, the coating is coated with a composition (solid content ratio of 15%) containing a solid lubricant and a compound or an organic binder shown in Tables 1 and 2, and t...

Embodiment approach B

[0134] B-1 steel plate for hot pressing

[0135] B-1-1) Coating

[0136] In this embodiment B, in order to suppress the diffusion of Zn in the plating layer to the base steel sheet and obtain excellent pitting corrosion resistance, a plating layer containing 60% by mass or more of Ni and the balance consisting of Zn and unavoidable impurities is provided on the surface of the steel sheet. I. When the amount of Ni in the plating layer I is less than 60% by mass, diffusion of Zn in the plating layer to the base steel sheet cannot be sufficiently suppressed, and excellent pitting corrosion resistance cannot be obtained. The amount of Ni in the plating layer I is preferably 100% by mass, but when it is less than 100% by mass, the balance is Zn having a sacrificial anticorrosion effect and unavoidable impurities. In addition, when the adhesion on each side of the coating I is less than 0.01g / m 2 When , the effect of inhibiting the diffusion of Zn to the base steel plate cannot b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com