Self-insulation composite fireproof curtain wall board and preparation method thereof

A fire-proof curtain and self-insulation technology, applied in the direction of heat preservation, fire protection, walls, etc., can solve the problems of poor performance and complex structure, and achieve the effects of convenient installation, high efficiency and simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

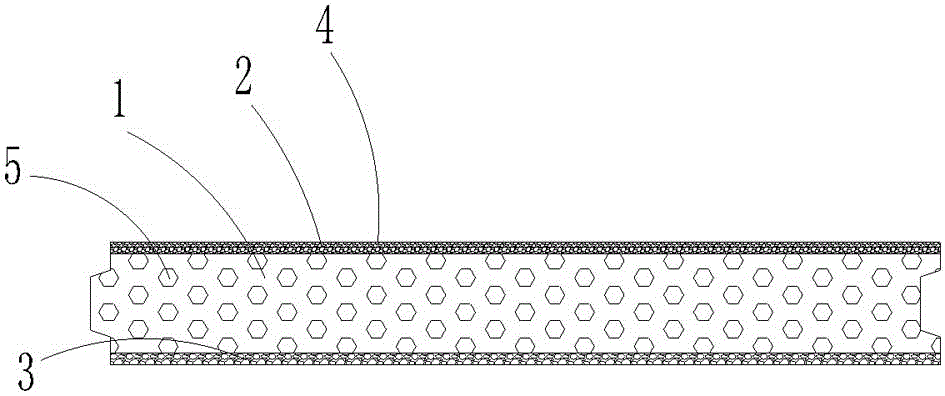

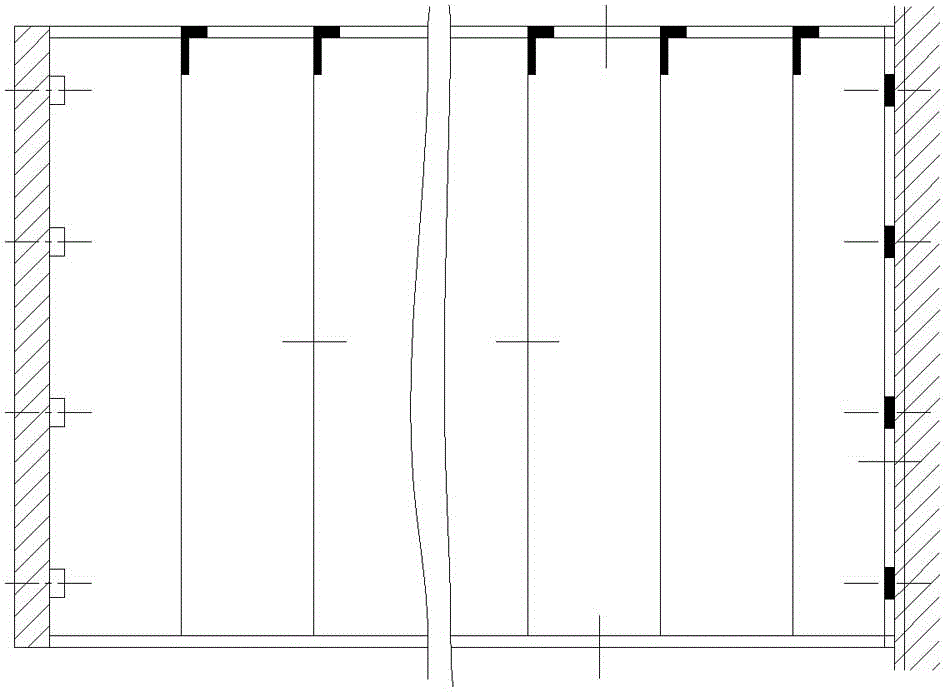

[0070] Embodiment 1: as figure 1 and figure 2 As shown, a self-insulation composite fireproof curtain wall panel includes a wallboard core layer 1, the outer wall of the wallboard core layer 1 is provided with a high-density CCA fiber cement board 2, and the inner wall of the wallboard core layer 1 is provided with There is a low-density CCA fiber cement board 3, and the outer wall of the high-density CCA fiber cement board 2 is provided with a marble-like paint layer 4.

[0071] The thicknesses of the high-density CCA fiber cement board 2 and the low-density CCA fiber cement board 3 are 5-10 mm respectively.

[0072] The wallboard core layer 1 is provided with evenly distributed EPS foam particles 5 .

[0073] The preparation method of self-insulation composite fireproof curtain wall panel is carried out according to the following steps:

[0074] (1), prepare wallboard core layer:

[0075] Ingredients: EPS foam particles, cement, fly ash, sand, adhesive;

[0076] When u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com