Perforation positioning grouting sleeve

A technology of grouting sleeves and positioning discs, which is applied to buildings, building reinforcements, building components, etc., can solve problems such as environmental pollution, inaccurate positioning, and easy tripping at joints, and achieve simple and efficient manufacturing processes. , the effect of a wide range of material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The perforated positioning grouting sleeve of the present invention will be further described below.

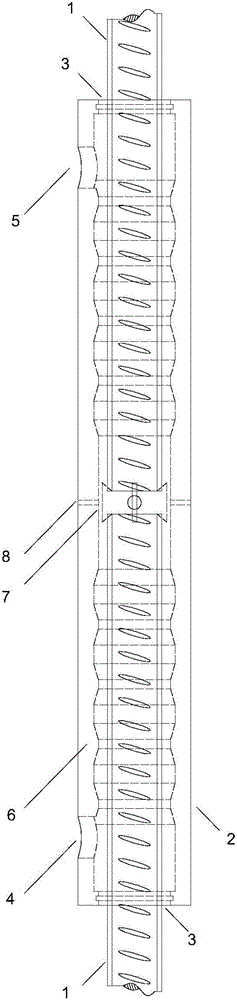

[0022] Perforated positioning grout sleeve, see figure 1 , including a seamless steel pipe 2 and a positioning plate 7; the inner wall of the seamless steel pipe 2 is lathe-processed to form a shear groove boss 6; Grouting holes 4 and grouting holes 5 are symmetrically arranged on the pipe wall at the end; a pair of positioning holes 8 are arranged in the middle of the seamless steel pipe 2 along the direction perpendicular to the length of the pipe as positioning points, which is convenient for iron wires to penetrate into the positioning plate 7 to determine the connected position. The position of the steel bar 1; the positioning plate 7 and the seamless steel pipe 2 are set relatively independently.

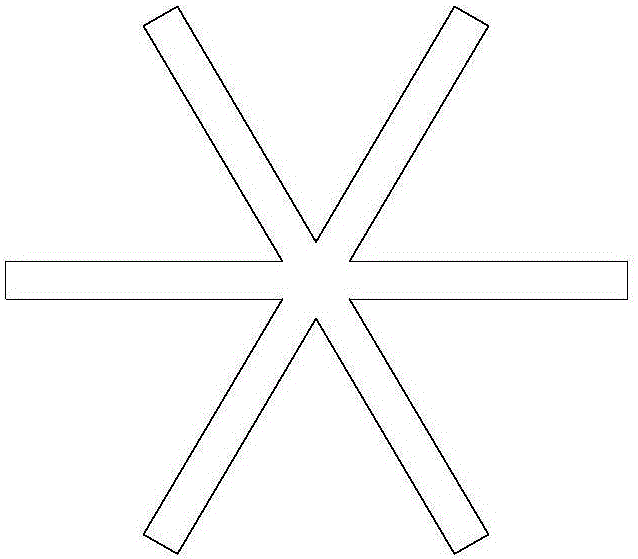

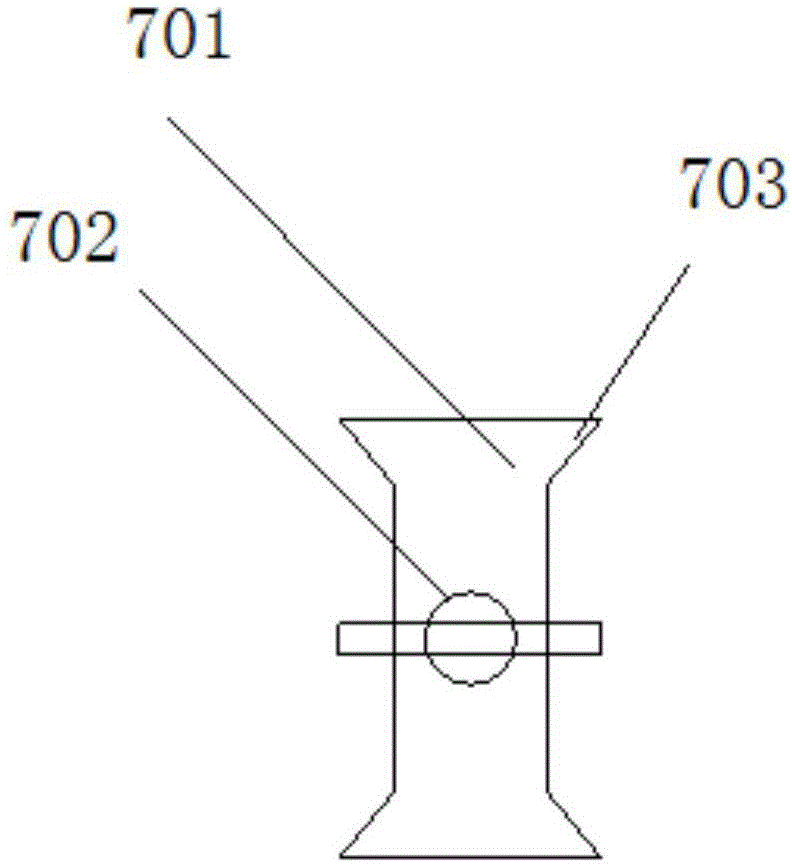

[0023] Positioning plate 7, such as Figures 2 to 4 As shown, the shape is snowflake-shaped, and it is a snowflake-shaped positioning plate composed of three equidis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com