Assembly type concrete wall board, assembly type building and assembly method

A concrete and prefabricated technology, which is applied in the direction of construction, building structure, and on-site preparation of building components, can solve the problems of weak seismic performance of buildings, poor stability of joints, and poor connection effect, etc., to achieve improved seismic performance, The effect of convenient construction and easy connection and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

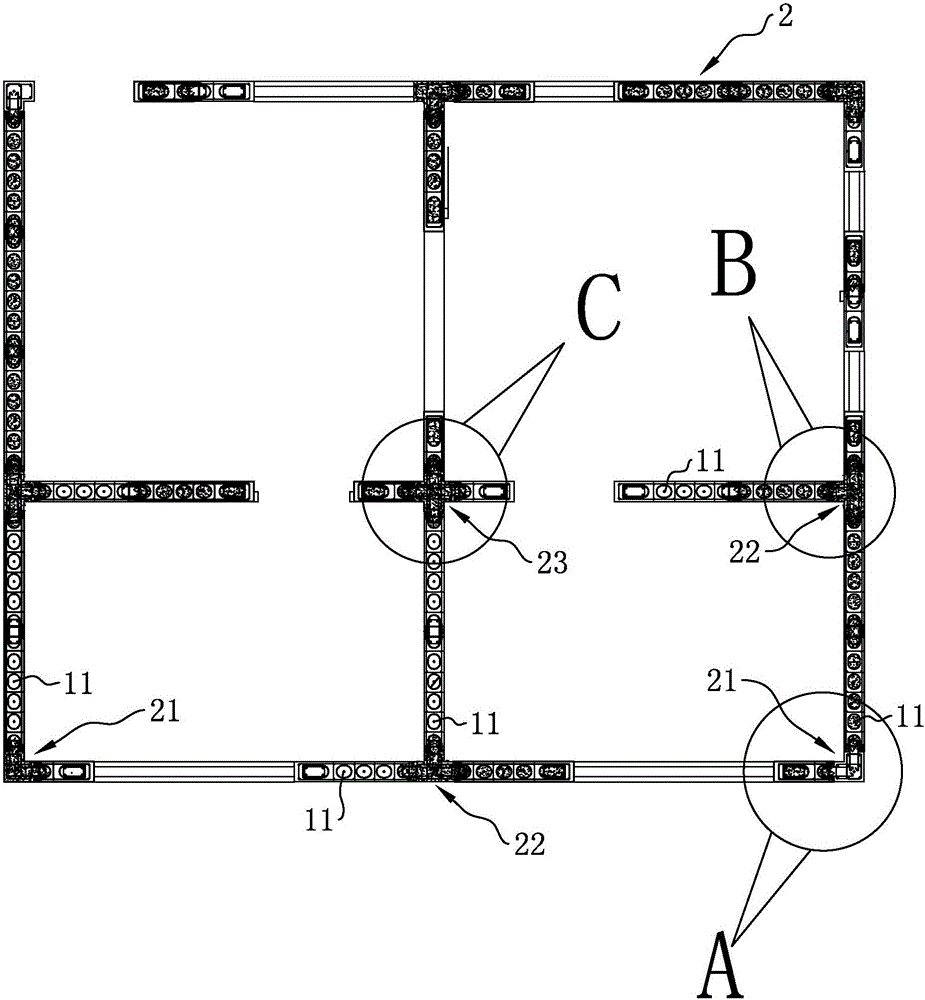

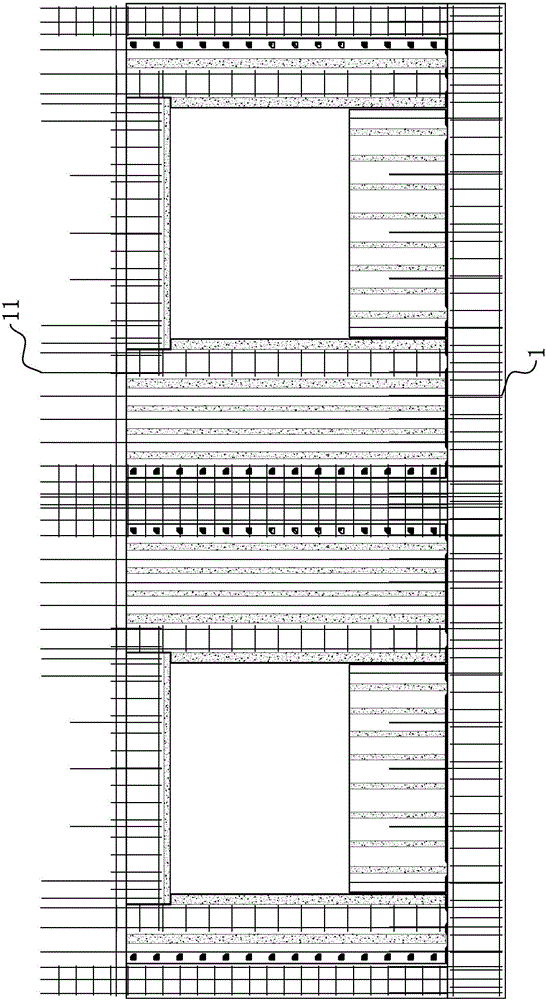

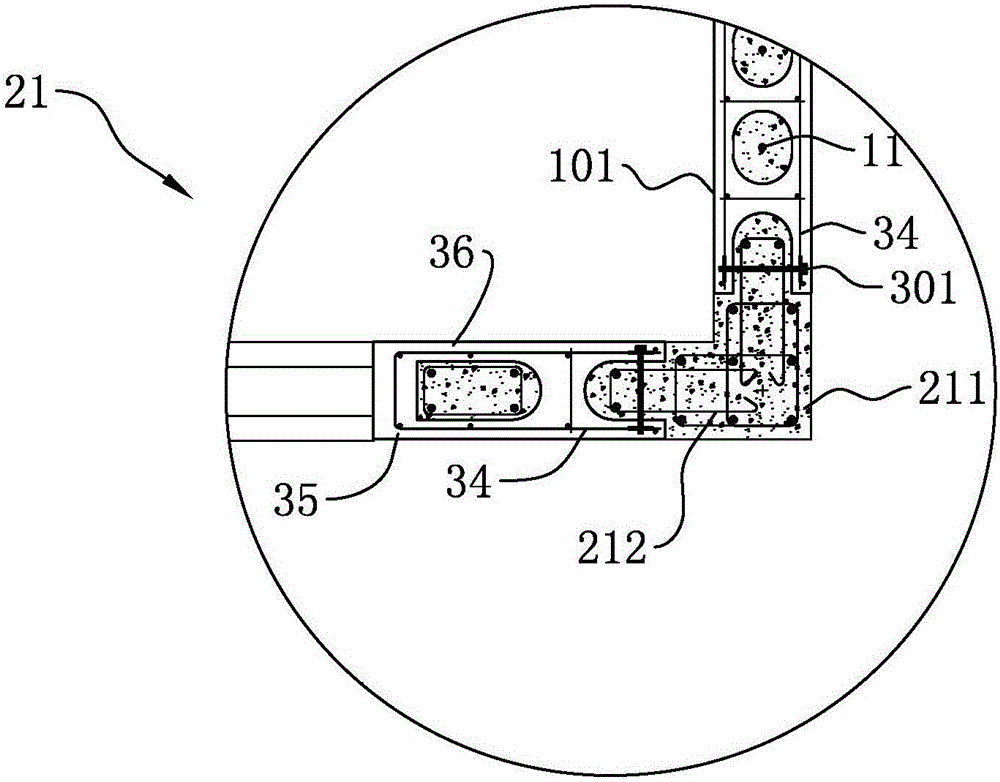

[0049] Such as figure 1 , figure 2 As shown, the prefabricated building of the present invention includes a foundation 1 (it can also be a lower wall, and this embodiment only takes the foundation as an example) and a wall panel 2 formed by butting and arranging a plurality of reinforced concrete prefabricated circular hole plate templates. . The corners of the wall panels 2 are connected by an "L"-shaped node connection part 21, the "T"-shaped intersection is connected by a "T"-shaped node connection part 22, and the "ten"-shaped intersection is connected by a "ten"-shaped node connection part 23 connect. Such as image 3 As shown, the "L"-shaped node connecting portion 21 includes an "L"-shaped column 211 that is cast-in-place at the corner and has an "L"-shaped reinforcement cage 212 inside. Such as Figure 4 As shown, the "T"-shaped node connection part 22 includes a "T"-shaped column 221 cast-in-place at the "T"-shaped intersection with a "T"-shaped steel cage 222 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com