Gas-liquid separator for oil field

A technology of gas-liquid separator and cyclone separator, which is applied in the chemical/physical/physical chemical process of energy application, production fluid, wellbore/well components, etc., which can solve equipment corrosion, sharp increase of gas content, and poor effect Obvious problems, to achieve the effect of accelerated desorption, increased desorption rate, and effective desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0024] Preferred embodiment:

[0025] This preferred embodiment provides a gas-liquid separator for oilfields, the gas-liquid separator includes a housing 1, and an ultrasonic system is arranged in the housing 1, and the desorption of carbon dioxide gas in the production fluid is improved by the ultrasonic waves generated by the ultrasonic system rate, solves for CO 2 A large amount of CO dissolved in the produced fluid after gas channeling in the oil flooding field 2 The problem of gas not desorbing quickly.

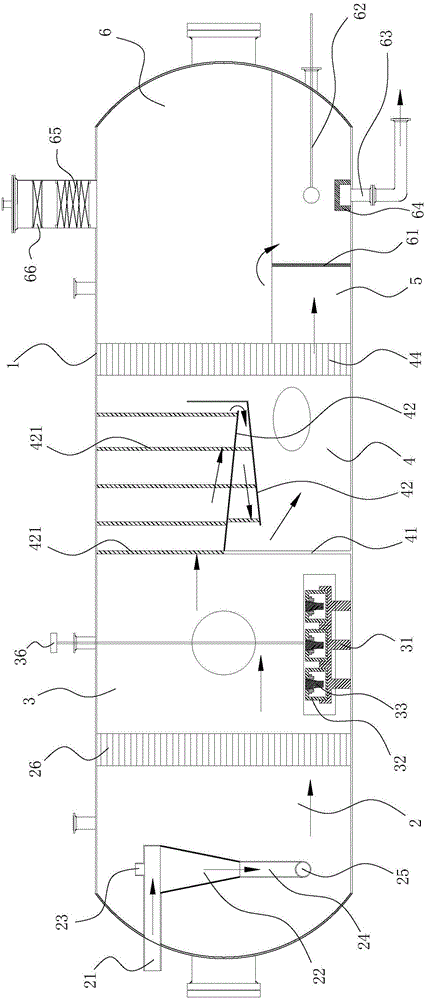

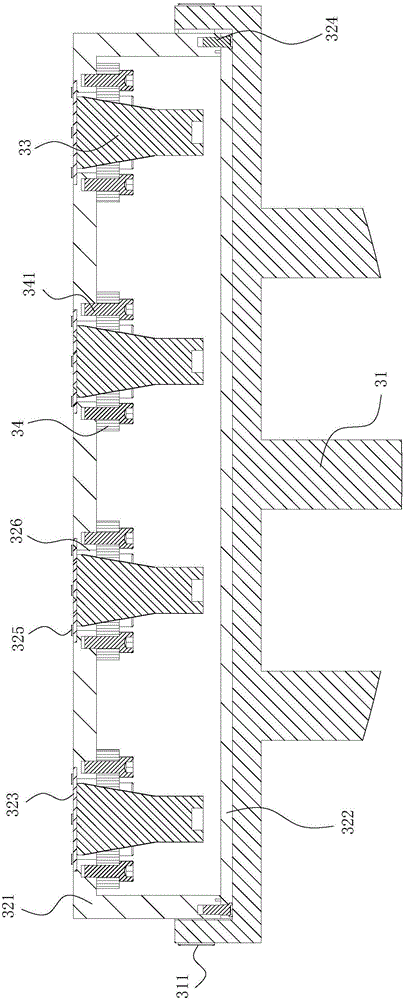

[0026] Such as figure 1 As shown, the preferred structure of the gas-liquid separator comprises a horizontal cross-section cylindrical housing 1, in which a primary separation chamber 2, a secondary separation chamber 3, a defoaming chamber 4, a settling chamber 5 and Oil chamber 6; the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com