Tripod universal joint and heavy load type transmission shaft assembly

A technology of three-ball pins and universal joints, which is applied in the direction of couplings, elastic couplings, clutches, etc., can solve the problems of small slippage of ball rings, damage of three-ball pins, and large slip resistance, and achieve assembly And the effect of easy disassembly, saving replacement cost, and large swing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

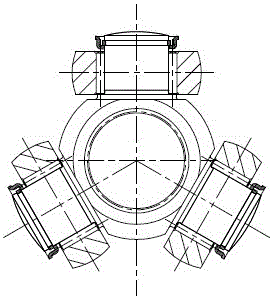

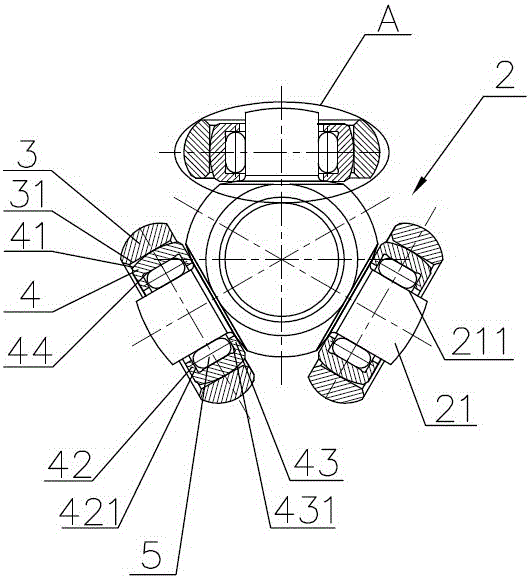

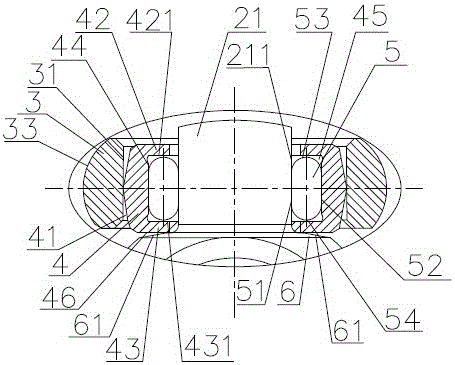

[0034] As shown in the figure, a three-ball pin type universal joint includes a universal joint housing 1, which is formed with three raceway grooves 12 having a double-ball ring unit guide surface 11 symmetrically arranged in the circumferential direction; pin member 2, which has three pin shafts 21 protruding radially; a double ball ring unit, which has an outer ball ring 3 and supports the outer ball ring 3 in a direction orthogonal to the axis and in parallel with the axis The inner ball ring 4 is freely rotatable in the direction of the inner ball ring. The outer peripheral surface 41 of the inner ball ring is in line contact with the inner peripheral surface 31 of the outer ball ring. A needle roller 5 is arranged between the ball rings 4 , and the inner peripheral surface 51 of the needle roller contacts the outer peripheral surface 211 of the pin sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com