Air-cooling-type cooler

A cooler and air-cooled technology, applied in the direction of indirect heat exchangers, heat exchanger fixation, heat sinks, etc., can solve the problem that the cooling pipes and fins are easily blocked by dust, the cooling fins have limited heat dissipation capacity, and increase maintenance Frequency and other issues, to achieve good insurance effect, convenient space collocation and layout, and optimize the installation plan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

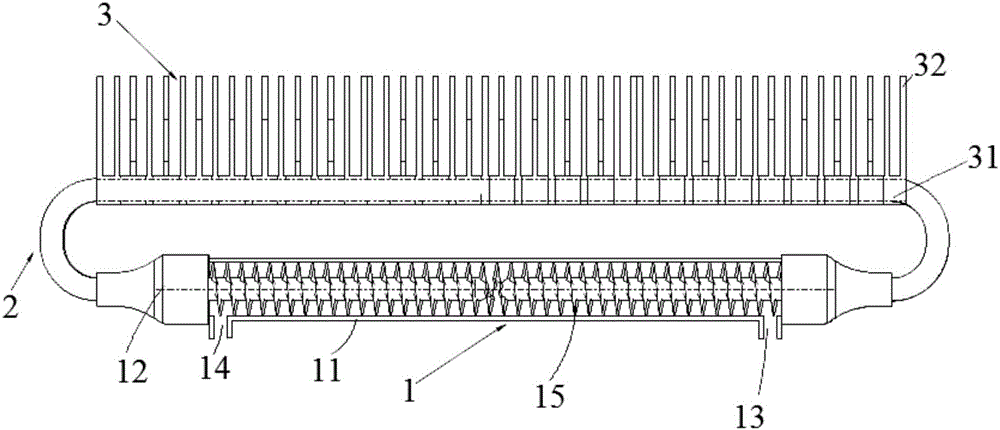

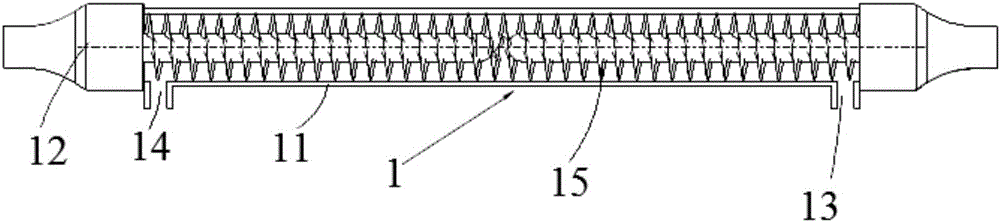

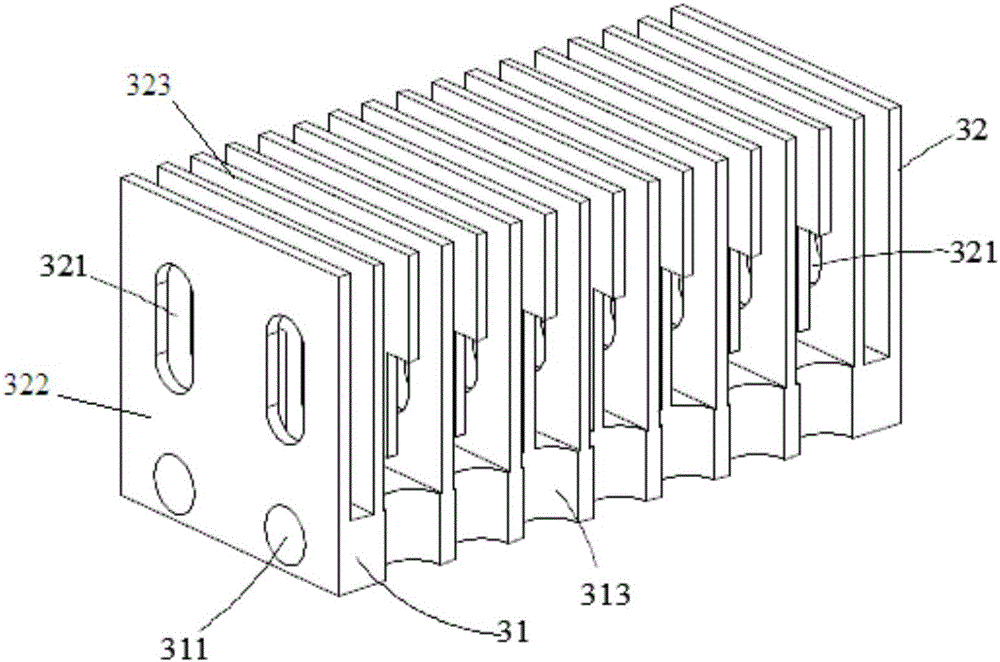

Embodiment 1

[0038] Such as Figure 1 to Figure 7 As shown, the air-cooled cooler provided in this embodiment includes an exchanger 1 , a conductor 2 and a heat dissipation group 3 , and the exchanger 1 is connected to the heat dissipation group 3 through the conductor 2 . The main feature of the present invention is to transfer energy, which can be simply understood as separating the exchanger from the heat dissipation group 3, no longer using the cooling pipe wall as the heat transfer object, but using superconducting heat pipes to separate the transfer, and then the heat dissipation group 3 dissipates heat , to achieve the purpose of cooling. During the cooling operation, the heat source fluid completes the energy exchange in the exchanger 1, and the conductor 2 transfers the energy to the heat dissipation group 3 for heat dissipation to achieve the cooling effect, thereby solving the defect of relying on the heat transfer of the tube wall, and then making the cooling tube do Relativel...

Embodiment 2

[0051] Such as Figure 8 As shown, the difference from Embodiment 1 is that the cooling group 3 is replaced by the exchanger 1 . In this embodiment, different functions can be obtained by expanding the heat dissipation end. When the heat dissipation group 3 is replaced by the exchanger 1, that is, two exchangers 1 are combined, one exchanger 1 is for cooling fluid, and the other is for heat source. The fluid thus achieves the cooling effect, and the cooling effect is superior. The biggest advantage of this structure is that the cooling section and the heat source section are completely separated, and the two different materials used in the system will not be connected to each other due to the rupture and damage of the conductor 2, which will cause the failure to expand. Because the heat source The relationship between the two substances and the cooling source are often different and incompatible or even very taboo. The coolers used by the traditional two-fluid all have the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com