Measurement and calculation method of turbine shaft system center

A steam turbine and shafting technology, which is applied in the field of measuring and calculating the center of steam turbine shafting, can solve the problems of reducing the efficiency of measuring and calculating the center of steam turbine shafting, reducing the speed of measuring and calculating the center of steam turbine shafting, and the direction of numerical value is prone to errors, so as to reduce the amount of measurement and calculation. Possibility of mistakes, fast calculation speed, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing.

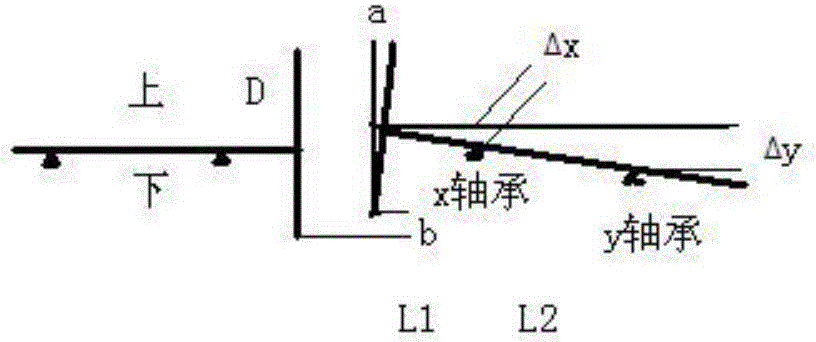

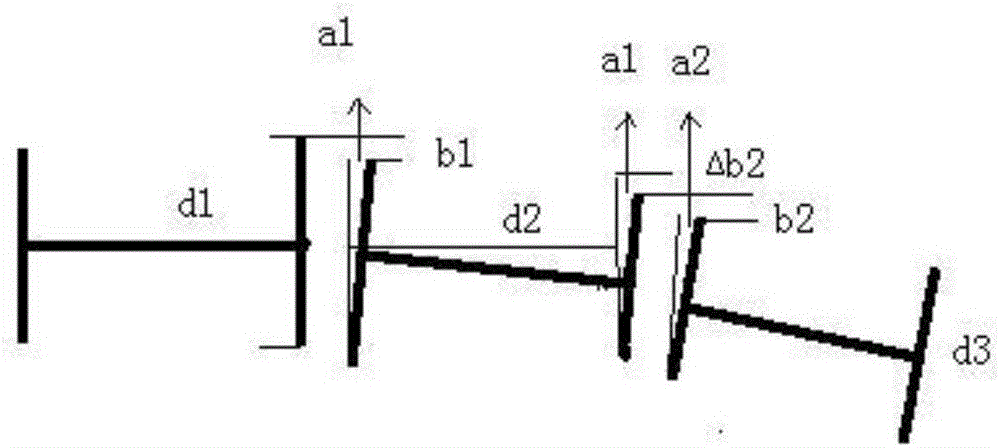

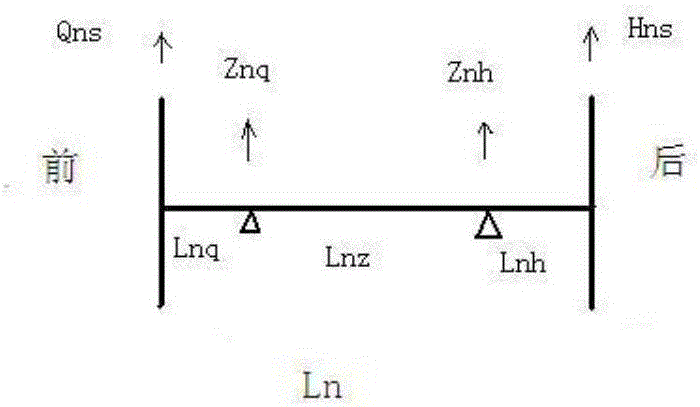

[0038] 1. Establish a measurement model

[0039] In the process of calculating and adjusting the center of the shaft system, there is a frequently used value, which is the adjustment amount of the backrest wheel during the adjustment process. For a certain rotor, the adjustments of the two bearings can be calculated under the condition that the adjustments of the back wheels at both ends of the rotor are determined. And the adjustment amount of the backrest wheel can be calculated simply and conveniently according to the circumference and opening of the backrest wheel.

[0040] For the convenience of calculation, first establish a calculation model:

[0041] (1) All rotors are rigid bodies, and there is no deformation due to gravity, rotation and other factors;

[0042] (2) The centerline of the rotor is a straight line, the cross-section of any part is a circle with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com