Power module structure and manufacture method thereof

A technology for power modules and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve problems such as joint damage, low power density of power modules, chip failure, etc., and saves layout. area, increase power density, and realize the effect of compactness and miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] As mentioned in the background technology section, in the prior art, the main switching device (such as IGBT or MOSFET) and the freewheeling diode (such as FRD or SiC SBD) are arranged side by side on the same plane in the existing power module, so that the power module The power density is too small.

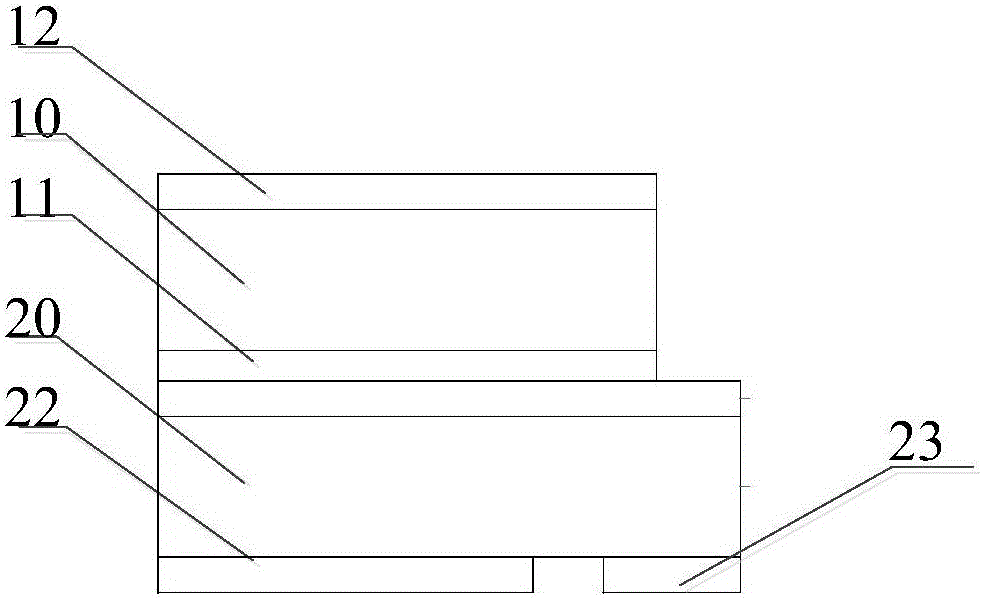

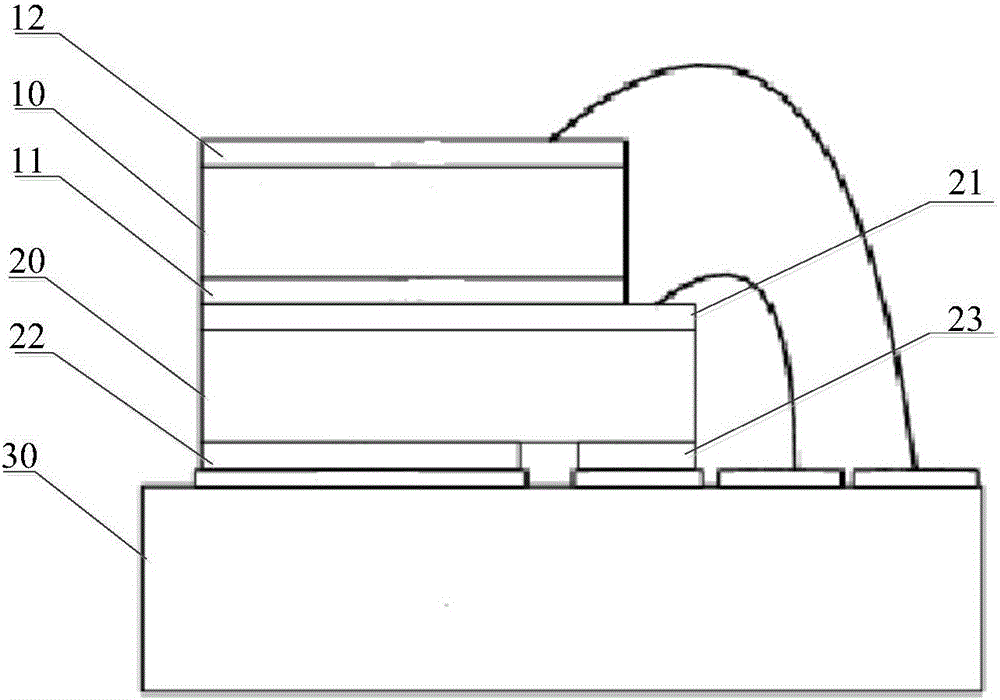

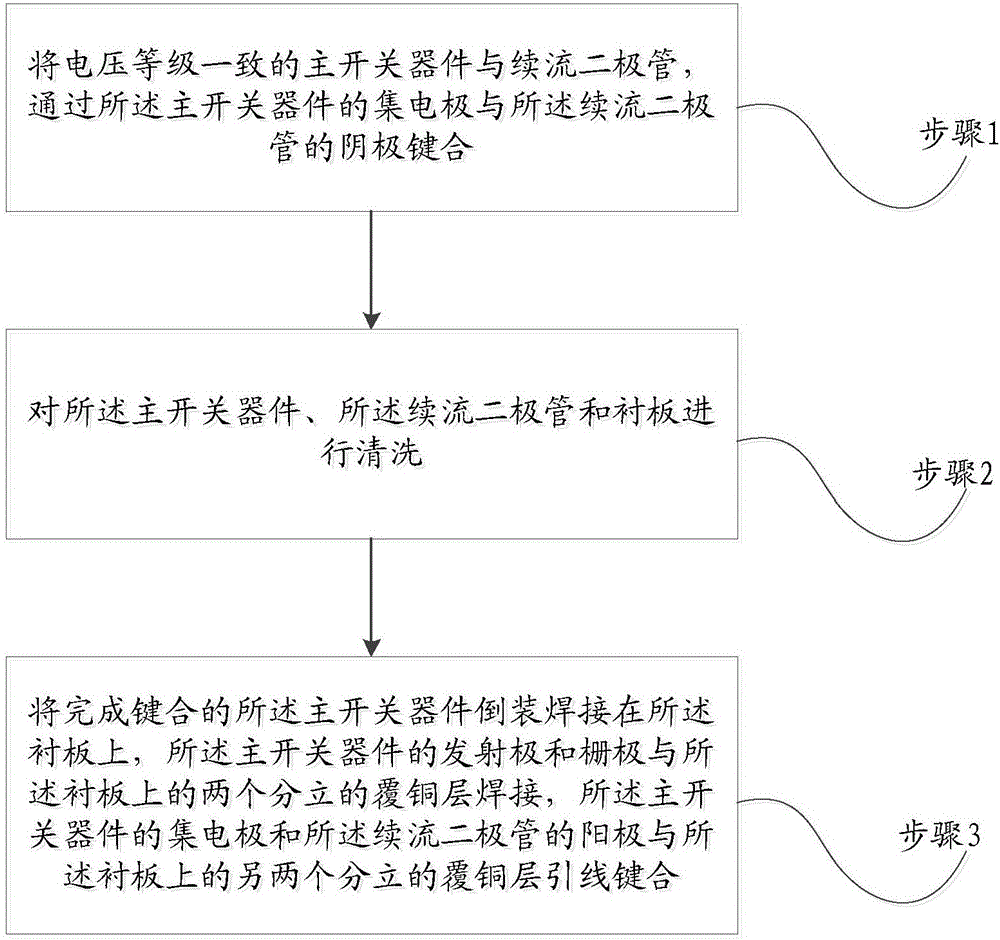

[0030] Based on this, an embodiment of the present invention provides a power module structure, including a main switching device, a freewheeling diode and a substrate, the voltage level of the main switching device and the freewheeling diode are consistent, and the current magnitude is the same. After the collector of the switching device is bonded to the cathode of the freewheeling diode, the main switching device is flip-chip welded on the backing board, and the backing board is provided with a plurality of discrete copper clad layers, wherein the The emitter of the main switching device is welded to the first copper clad layer on the lining board, the gate is welded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com