Water-cooling motor shell

A water-cooled motor and water channel technology, applied in the electrical field, can solve the problems of troublesome layout of the whole vehicle and can only be arranged on two adjacent water channels near one end of the casing, and achieves reliable structural design and is conducive to heat dissipation. , to meet the effect of lightweight design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A water-cooled motor case of the present invention will be further described in detail below in conjunction with the accompanying drawings.

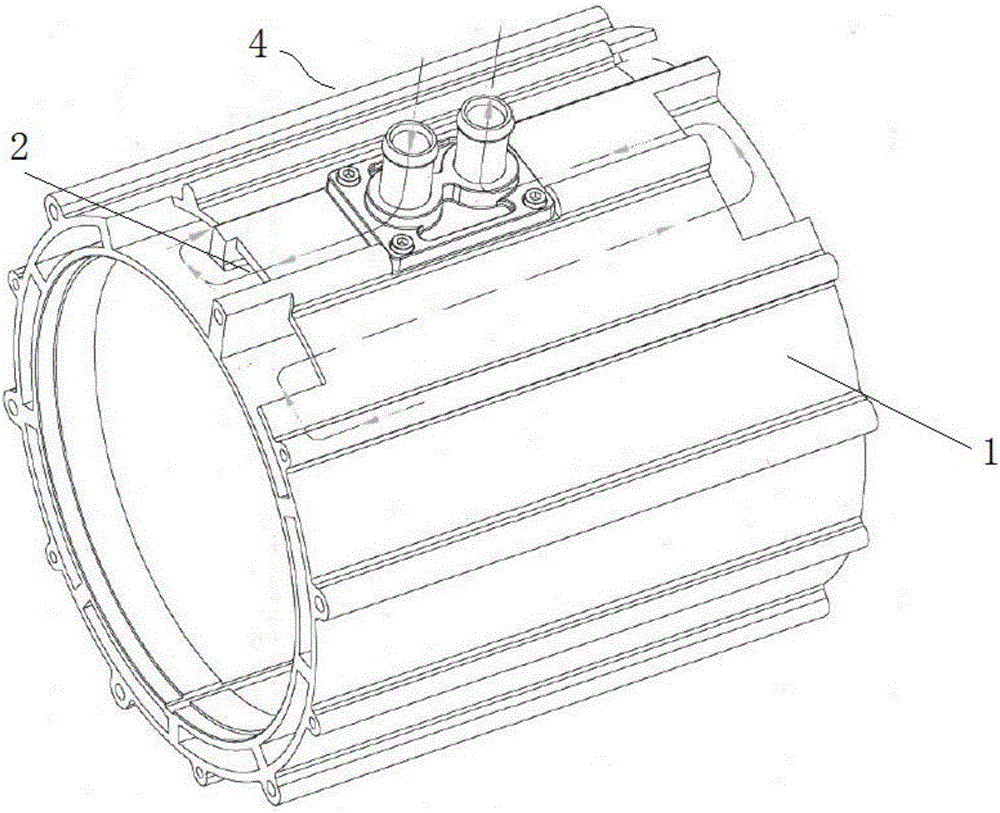

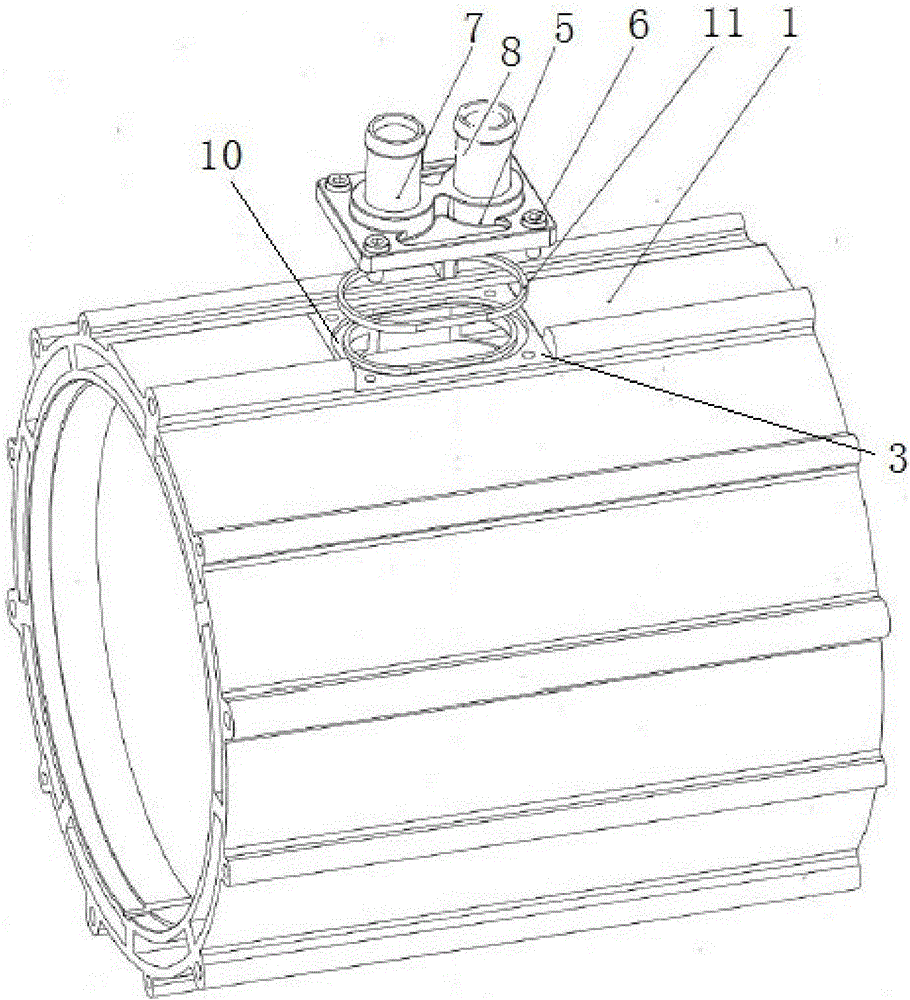

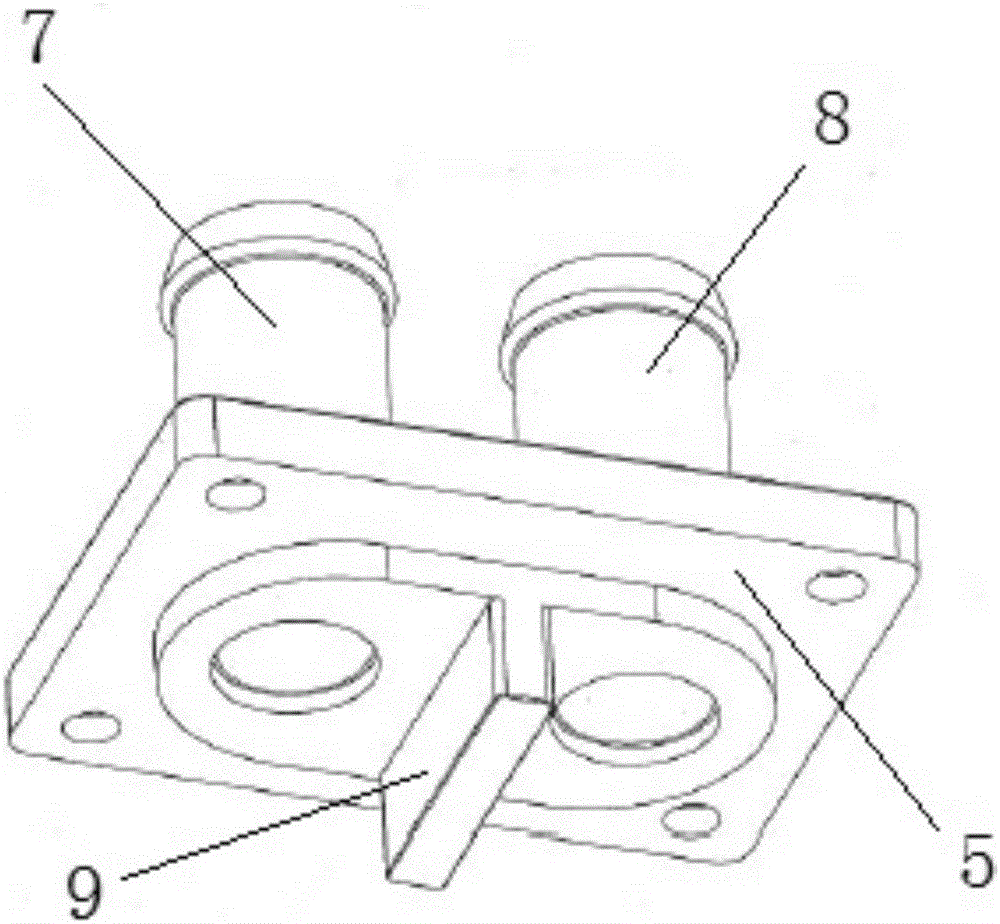

[0015] Such as Figure 1 to Figure 4 As shown, a water-cooled motor casing of the present invention integrates the water inlet pipe 7 and the water outlet pipe 8 into a flange 5, and a water retaining plate 9 is designed between the water inlet pipe 7 and the water outlet pipe 8, and the water retaining plate 9 The height and width dimensions are consistent with the cavity size of the water channel 2. The shell 1 is designed with a platform that matches the water inlet pipe 7 and the water outlet pipe 8. A mounting groove 3 that matches the water pipe flange 5 is processed on the shell 1. The groove 10 and the screw hole, after the assembly is completed, fit between the side wall and the bottom surface of the water channel 2, and separate the water inlet pipe 7 and the water outlet pipe 8 to form two cavities. The assembly relatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com