Composite ceramic membrane and preparing method thereof

A technology of composite ceramic membrane and support body, applied in the field of ceramic membrane, can solve the problems of system shutdown, easy rupture, unqualified water production, etc., and achieve the effect of reducing production loss, reducing dead volume, and reducing investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

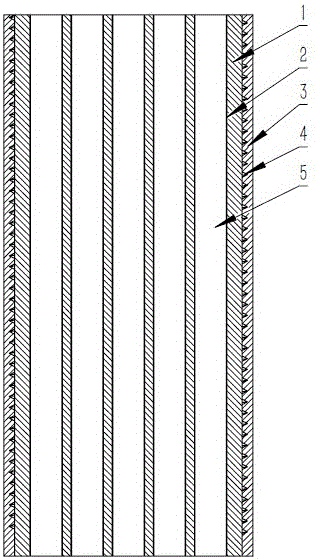

[0052] figure 1 Schematically provides a cross-sectional structure diagram of the composite ceramic membrane of Example 1 of the present invention, as figure 1 As shown, the composite ceramic membrane includes:

[0053] A honeycomb ceramic membrane support body 1 and a ceramic membrane 2 with a fluid channel 5, the ceramic membrane and its support body are prior art in the art, and will not be repeated here;

[0054] Reinforcement layer 3, the reinforcement layer is sleeved on the outside of the support body, the inner wall of the reinforcement layer has grooves 4 arranged from top to bottom, and the space between the grooves and the outer edge of the support body is formed as a permeation side channel, The permeate side channel forms a space between the groove and the outer edge of the support body.

Embodiment 2

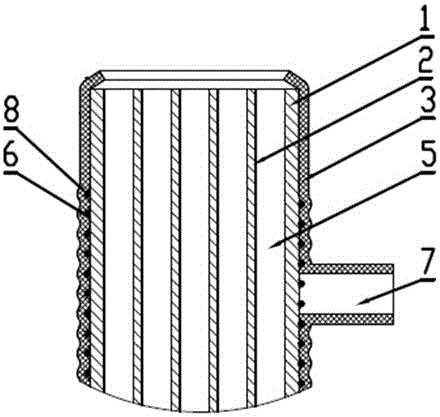

[0056] figure 2 Schematically provides the structure diagram of the composite ceramic membrane of the embodiment of the present invention 2, as figure 2 As shown, the composite ceramic membrane includes:

[0057] The ceramic membrane support body 1 and the ceramic membrane 2 having the fluid channel 5, the ceramic membrane and its support body are prior art in the art, and will not be repeated here;

[0058] A reinforcement layer 3, the reinforcement layer is sheathed on the outside of the support body;

[0059] The support 8 is arranged between the support and the reinforcement layer; the permeation side channel 6 forms a space between the support, the support and the reinforcement layer, and the permeation side channel 6 communicates with the outlet 7 .

Embodiment 3

[0061] An application example of the ceramic membrane according to Embodiment 1 of the present invention.

[0062] In this application example, the geometric dimensions: the external diameter of the ceramic membrane tube support is 41 mm, the channel diameter is 6 mm, the number of channels is 19, and the length is 1000 mm. The reinforcement layer is made of PFA plastic, in which the thickness of the PFA tube is 2mm and the inner diameter is 41mm, and the PFA tube is tightly sleeved on the ceramic membrane support. The inner wall of the PFA tube is provided with a helical top-down triangular groove with a depth of 0.5 mm to form a fluid channel on the permeate side of the ceramic membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com