Automatic welding device of coaxial cable outer conductor and adapter base and welding method

A coaxial cable, automatic welding technology, used in auxiliary devices, welding equipment, soldering irons, etc., can solve the problems of loss of base station antenna performance, unstable equipment temperature, unstable welding quality, etc., to overcome low work efficiency and welding quality. Good, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

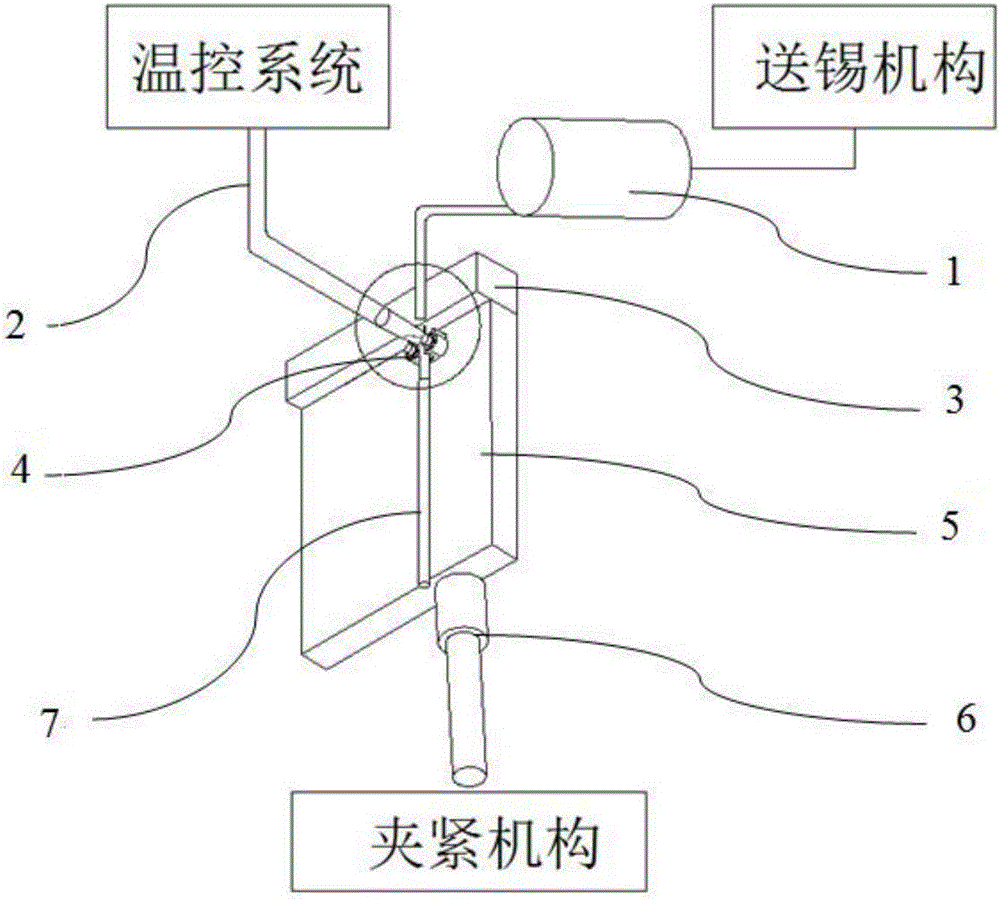

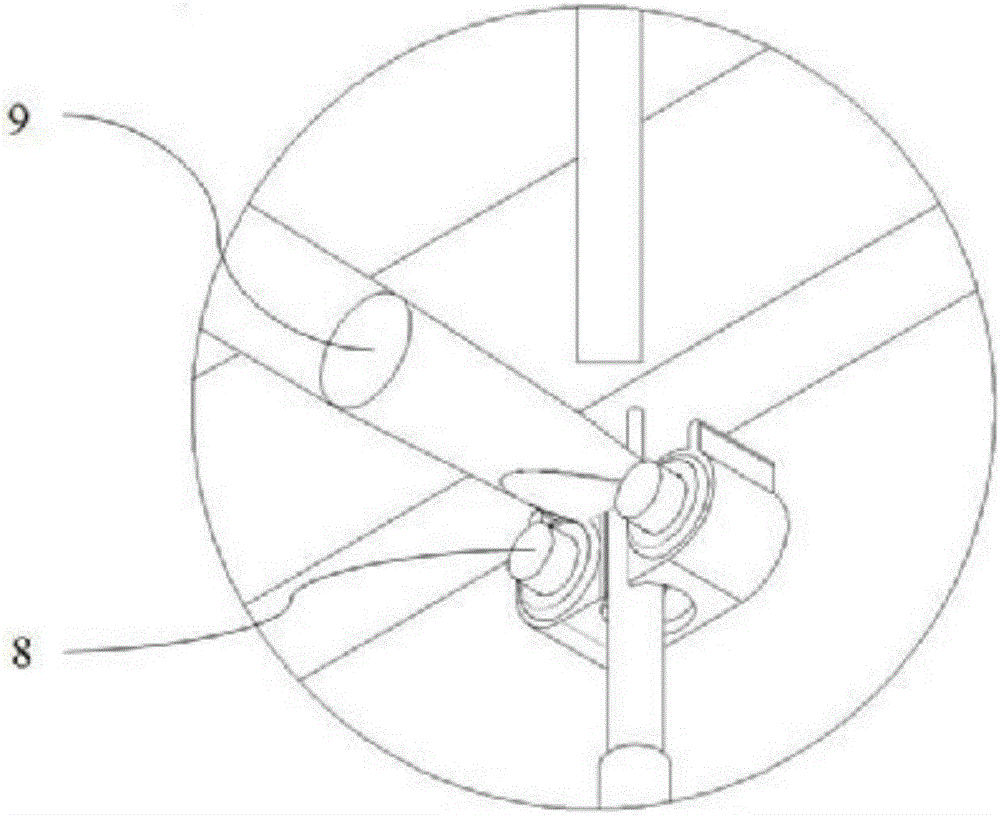

[0016] Such as figure 1 and figure 2 Shown, an automatic welding device for a coaxial cable outer conductor and an adapter seat of the present invention includes a special fixture, the special fixture includes a clamp body 5 and a clamping mechanism 6, and the clamp body 5 is composed of the clamping mechanism 6 and the limit fixing block 3 clamping and fixing; the clamp body 5 is provided with a fixed pin 8, the adapter base 4 is fixed by the fixation pin 8, and the coaxial cable 7 passes through the adapter base 4; a soldering iron tip 9 and a temperature control system are arranged above the adapter base 4 2 and the tin feeding mechanism 1, and the soldering iron tip 9 is connected with the temperature control system 2.

[0017] The welding method of the above-mentioned welding device is as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com