Heating device for bus-bar manufacturing

A heating device and busbar technology, which is applied in the field of busbar manufacturing heating devices, can solve the problems of low energy efficiency utilization, affecting the speed of finished products, and large energy consumption, so as to achieve smooth gas flow performance, cost saving, and good cooling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

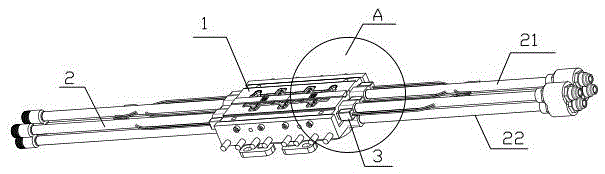

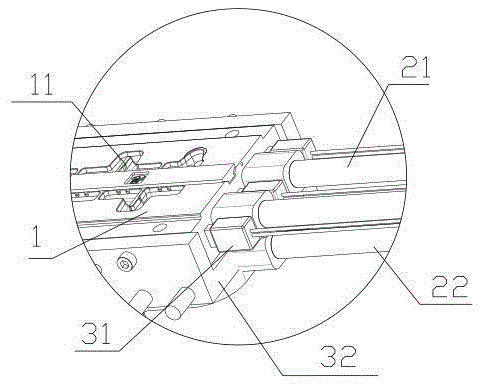

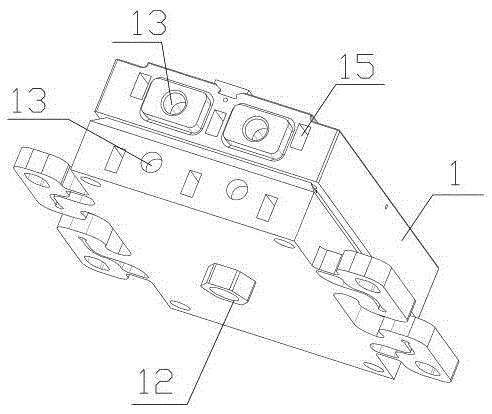

[0044] Example 1, such as figure 1 , figure 2 , Figure 8 , Figure 9 Shown: a busbar manufacturing heating device, including a mold 1, the mold 1 includes a molding groove 11, and also includes a heating component 3, and the heating component 3 includes a constant temperature heating component 32 for providing stable and continuous heat to the mold 1 and The rapid heating assembly 31 is used to heat up the mold 1 rapidly. The rapid heating assembly 31 is connected to the mold 1 through the heating channel 15 provided in the mold 1 .

[0045] The manufacturing process of the busbar is a complex process, and there are different requirements for temperature between multiple processes. In this technical solution, the mold 1 is placed outside the lead pot and placed outside the lead pot when heating. The liquid is introduced into the molding tank 11 in the mold 1. Before the introduction, the mold 1 is kept in a relatively high temperature range through the constant temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com