Traction device for seam welder

A technology of traction device and seam welding machine, applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of high production cost, high failure rate, complex structure, etc., and achieve the effect of compact structure and improved rotation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

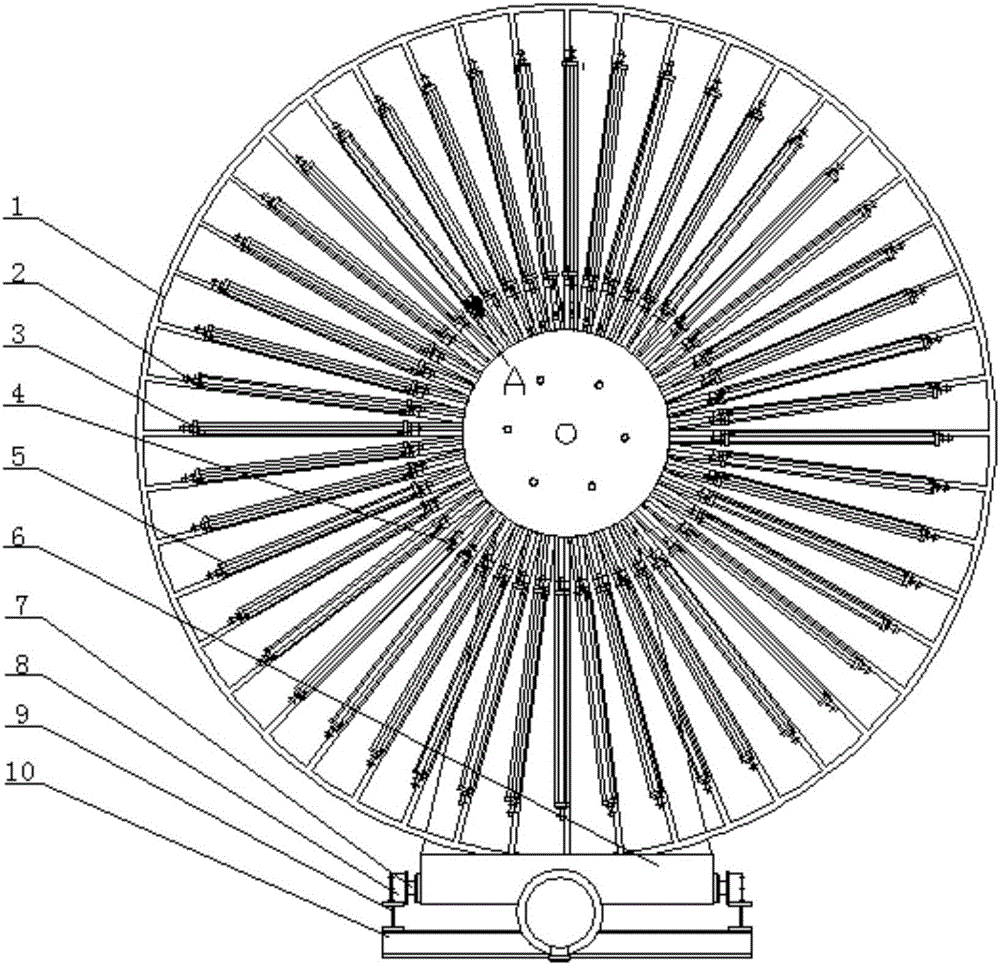

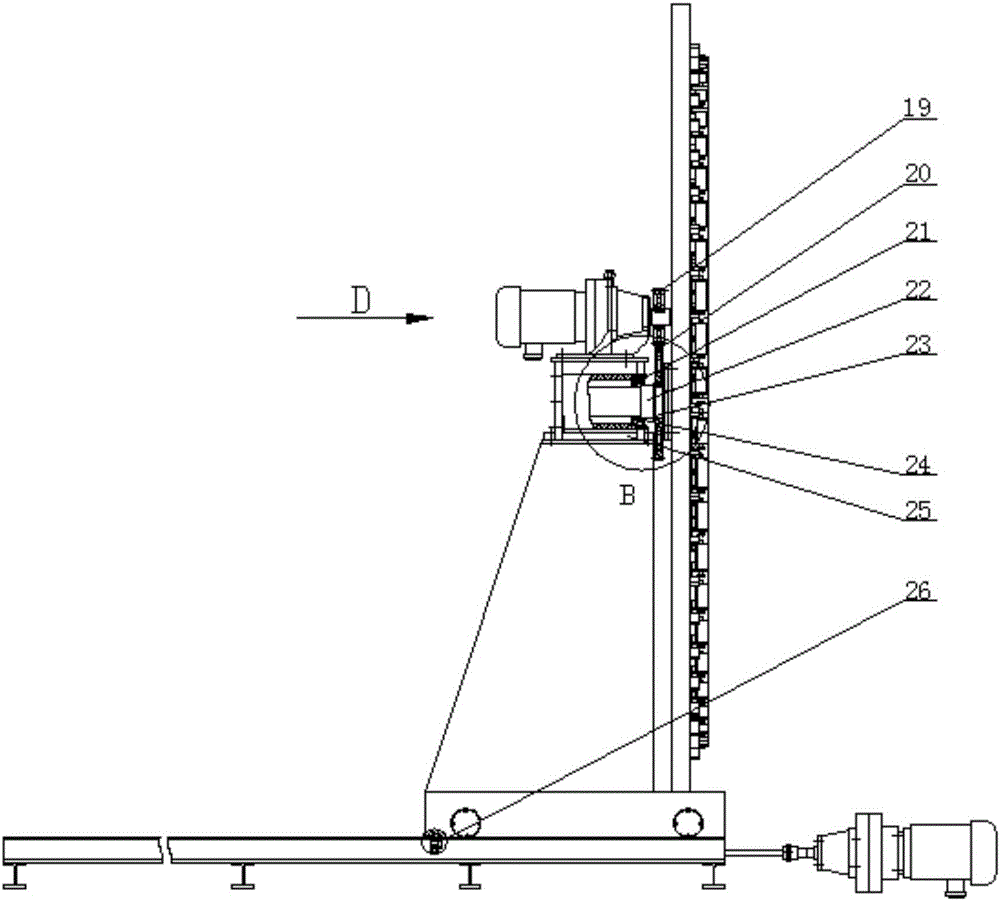

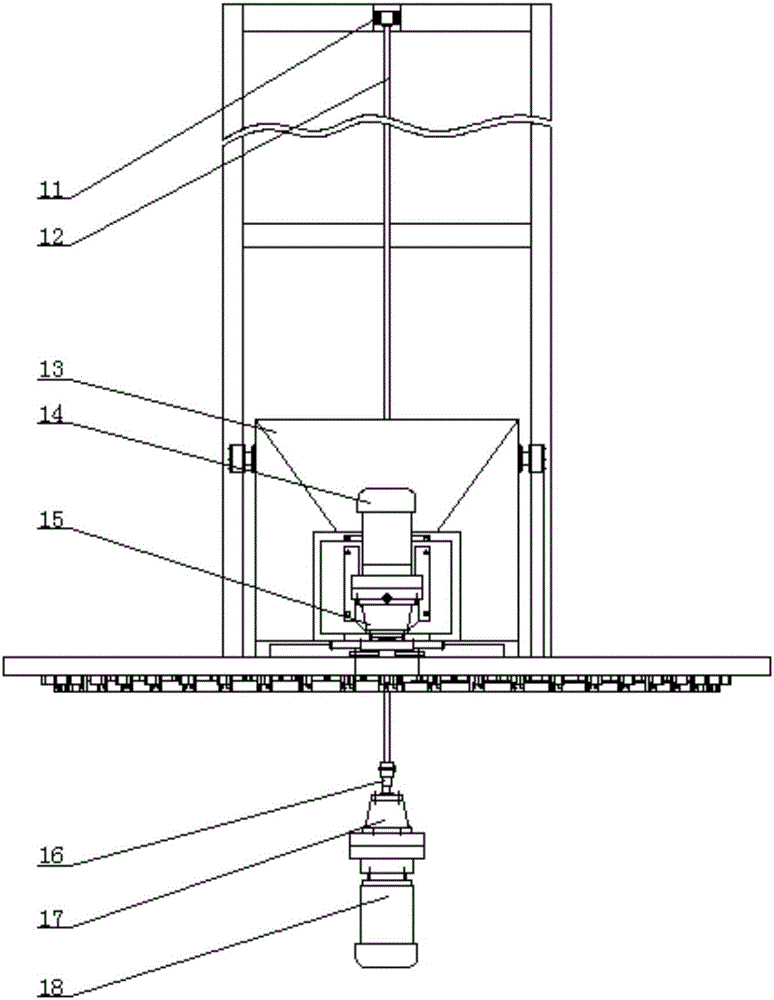

[0035] See Figure 1 to Figure 4 , The present invention provides a pulling device for a seam welding machine, comprising a pulling faceplate assembly, a pulling faceplate driving support assembly, a clamping assembly and a pulling faceplate dragging assembly. Among them, the traction faceplate assembly clamps the longitudinal reinforcement of the steel cage under the cooperation of the clamping assembly; the traction faceplate drive support assembly supports the traction faceplate assembly and drives the traction faceplate assembly to rotate; the traction faceplate dragging assembly drags the traction faceplate drive support Component longitudinal movement. The rotary cylinder of the clamping assembly drives the face gear to rotate. Through the face gear and bevel gear pair, multiple swing web axes can be rotated at the same time, so that multiple swing webs can rotate around their axes at the same time, and the distance between the fixed web and the fixed web can be changed....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com