Push-type foam pump and method for controlling spray volume thereof

A foam pump and push-type technology, which is applied in the field of push-type foam pump and its spray volume control, can solve the problems of inconvenient control of spray volume change, poor parts interference fit seal and movable fit seal structure design, etc., to achieve standardized production And automatic production efficiency, good sealing, good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

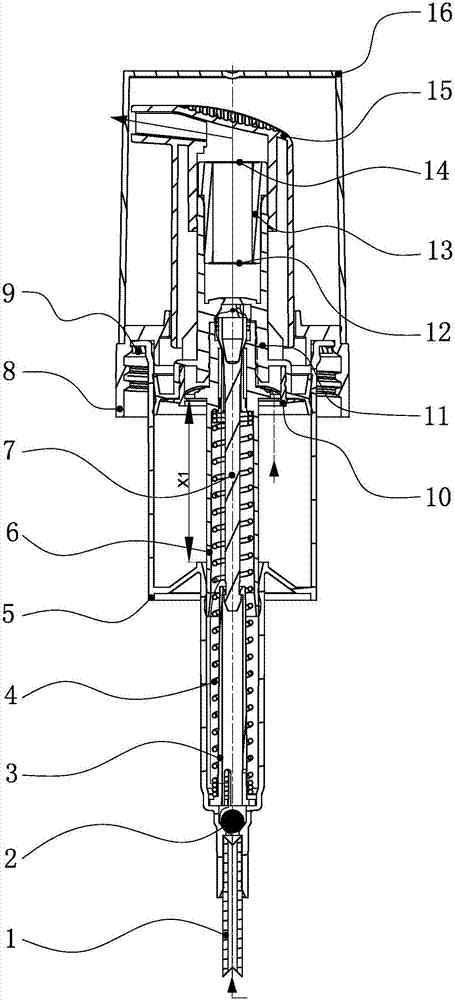

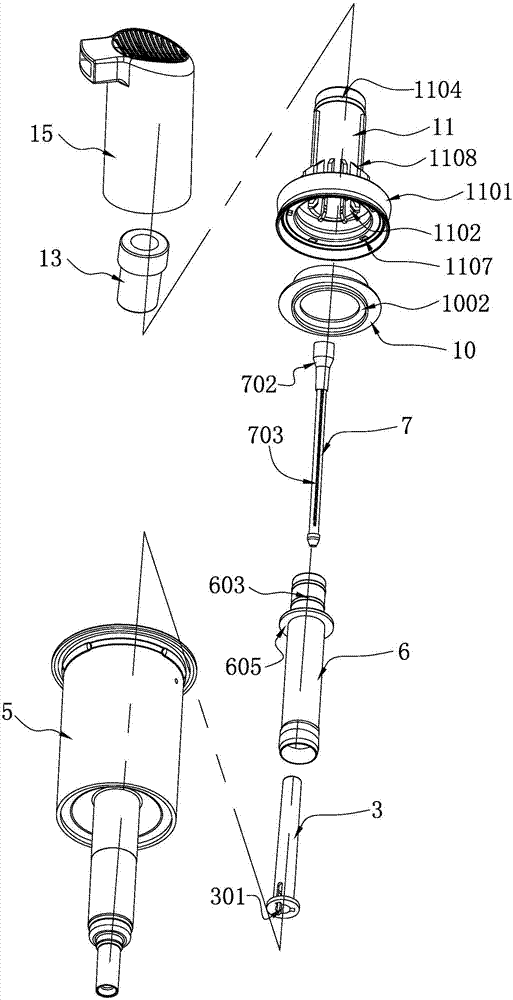

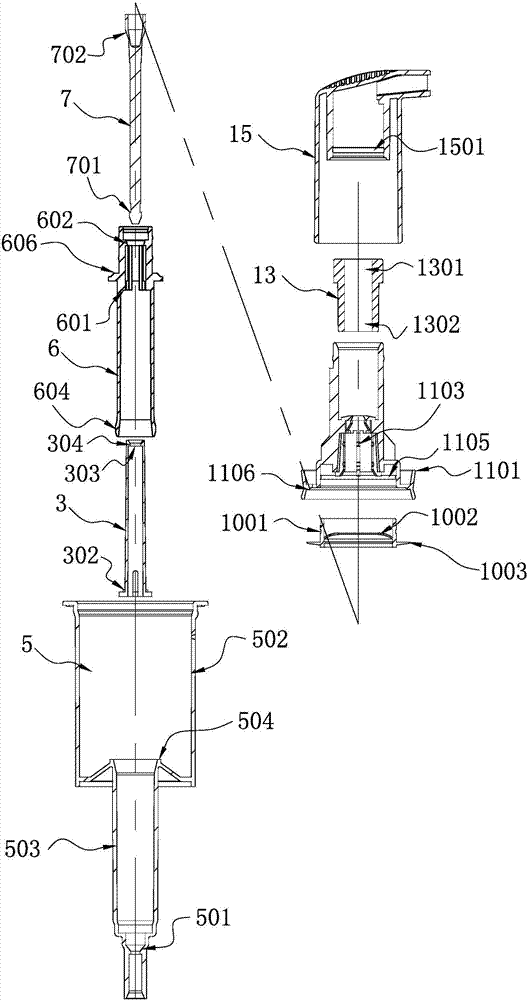

[0022] Now in conjunction with accompanying drawing, the present invention will be further described. Such as Figure 1 to Figure 8As shown, the foam pump includes a suction pipe 1, a glass ball 2, a spring sleeve 3, a spring 4, a pump body 5, a valve stem 6, a valve needle 7, a large ring 8, a gasket 9, a two-way valve 10, a piston 11, a thick wire Net 12, filter plug 13, fine wire mesh 14, duckbill 15, outer cover 16, the glass ball of this foam pump is placed in the suction pipe place in the pump body, and cooperates with the beating surface 501 of the pump body to move and seal, and is sealed by the bottom of the elastic sleeve. The lower sleeve hole 301 controls its beating stroke distance. The spring is inserted into the inner diameter of the valve stem and the outer diameter of the spring sleeve. The upper end of the spring stops at the valve hole rib 601 at the top of the inner diameter of the valve stem. The inner diameter of the spring passes through the valve needl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com