Liquid level display and automatic oil supply device for elevated oil tank

A liquid level display and oil supply device technology, which is applied to liquid distribution, transportation or transfer devices, distribution devices, special distribution devices, etc., can solve the problems of diesel engine parking, production and underground accidents, high risk factors, etc., to reduce labor Strength, improve reliability and stability, and ensure normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

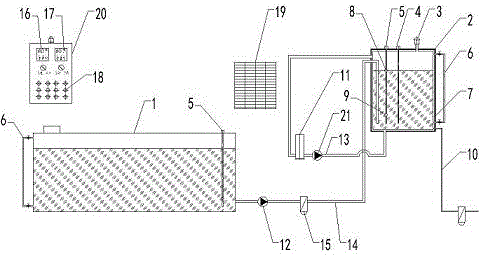

[0024] Examples such as figure 1 As shown, an elevated tank liquid level display and automatic oil supply device includes a floor oil tank 1 and an elevated oil tank 2, and the floor oil tank 1 and the elevated oil tank 2 are electrically connected at the same time for controlling the floor oil tank 1 to the elevated oil tank 2 Oil injection control system, the control system includes two parts of manual operation and automatic operation, the two parts can work at the same time, when the automatic operation part has an alarm fault that cannot be repaired, it can be controlled by the manual operation part.

[0025] The floor oil tank 1 and the elevated oil tank 2 are in sealed communication through the elevated oil tank oil supply pipeline 14, and one end of the elevated oil tank oil supply pipeline 14 communicated with the elevated oil tank 2 passes through the upper end of the elevated oil tank 2 position, and stretch into the position near the bottom in the elevated oil tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com