Self-sterilization plastic bag and preparation method thereof

A plastic bag, self-sterilization technology, applied in the field of plastic bag preparation, can solve the problems of poor antibacterial ability, easy to breed bacteria, rot, etc., and achieve the effects of strong mechanical strength, excellent sterilization ability and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

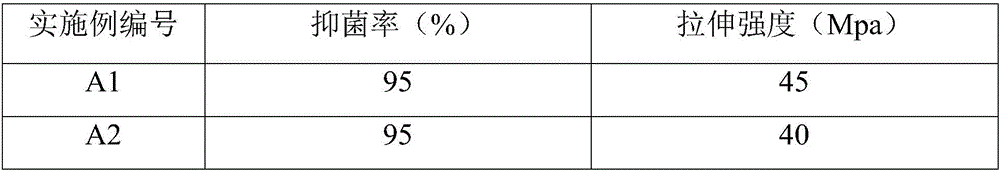

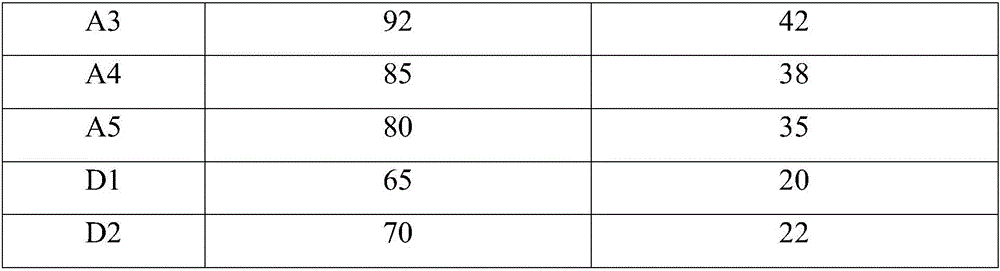

Examples

preparation example Construction

[0013] The invention provides a method for preparing a bactericidal plastic bag. The preparation method comprises: mixing polypropylene, acrylonitrile, phenolic resin, coupling agent and antioxidant, extruding and granulating to obtain a masterbatch M; Chitin, castor oil, horseradish and Prunella vulgaris are heated and mixed and then filtered to obtain the antibacterial agent N; blending the masterbatch M and the antibacterial agent N, and going through a film blowing process to obtain the bactericidal plastic bag; wherein, relative to 100 weight parts of polypropylene, the amount of the acrylonitrile is 20-40 parts by weight, the amount of the phenolic resin is 10-25 parts by weight, the amount of the coupling agent is 1-8 parts by weight, the antioxidant The consumption is 2-10 parts by weight, the consumption of said chitin is 2-10 parts by weight, the consumption of said castor oil is 5-10 parts by weight, the consumption of said horseradish is 1-8 parts by weight, the con...

Embodiment 1

[0022] After mixing 100g polypropylene (weight-average molecular weight is 6000), 25g acrylonitrile, 15g phenolic resin, 4g vinylsilane and 4g methylphenol, extrude and granulate to obtain masterbatch M; mix 4g chitin, 6g castor oil , 3g wasabi and 7g Prunella vulgaris were heated and mixed and then filtered (the temperature of heating and mixing was 60°C and the time was 20min) to obtain antibacterial agent N; masterbatch M and antibacterial agent N were blended, and the film blowing process was used to obtain antibacterial plastic Bag A1.

Embodiment 2

[0024] After mixing 100g polypropylene (weight-average molecular weight is 9000), 35g acrylonitrile, 20g phenolic resin, 6g aminosilane and 8g dimethylphenol, extrude and granulate to obtain masterbatch M; mix 8g chitin, 7g castor oil , 6g of horseradish and 9g of Prunella vulgaris were heated and mixed and then filtered (the temperature of heating and mixing was 75°C and the time was 25min) to obtain antibacterial agent N; the masterbatch M and antibacterial agent N were blended, and after the film blowing process, the antibacterial plastic was obtained Bag A2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com