Support material capable of being used for 3D printing and preparation method thereof

A supporting material and 3D printing technology, applied in the direction of additive processing, etc., can solve problems such as collapse, poor compatibility, product warping, etc., achieve good compatibility and bonding strength, and overcome the effect of product warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

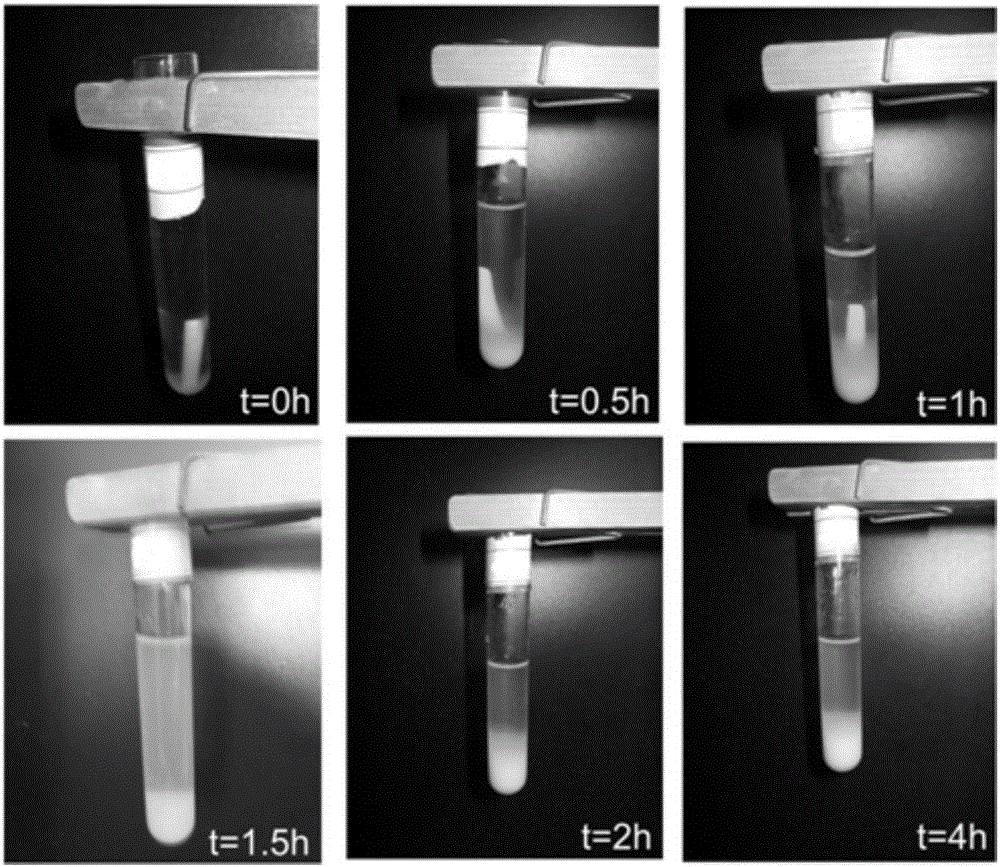

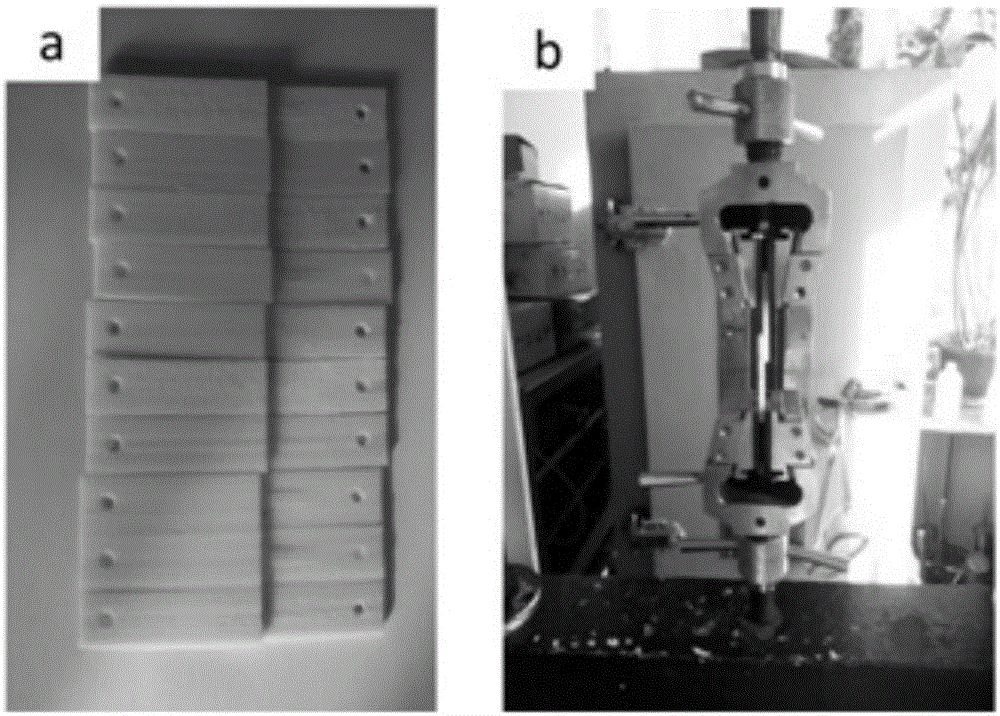

[0029] A support material that can be used for 3D printing. The support material is mainly composed of a matrix material with a content of 90 wt.% and a water-soluble material with a content of 10 wt.%. The matrix material mainly provides the strength required for the support material; the water-soluble material mainly provides the support material. water solubility.

[0030] Base materials are thermoplastic materials such as ABS, PLA, polyoxymethylene, polyethylene, polypropylene, polycarbonate, polymethyl methacrylate, nylon, polystyrene, polyvinyl chloride; water-soluble materials are polyvinyl alcohol, polyethylene oxide and other water-soluble polymers.

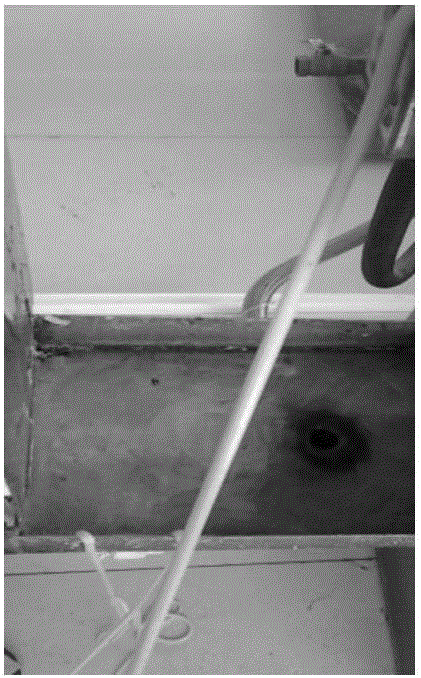

[0031] A kind of preparation method that can be used for the support material of 3D printing described above, its specific steps are as follows:

[0032] (1). Firstly, dry the base material and water-soluble material separately, the drying temperature is above 100°C, and the drying time is 2-12 hours;

[0033] (2). Twi...

Embodiment 2

[0037] A support material that can be used for 3D printing. The support material is mainly composed of four parts: matrix material, soluble material, compatibilizer and filler. The weight percentage of each component is: matrix material content 10 wt.%, water soluble The material content is 15 wt.%, the compatibilizer content is 25 wt.%, and the filler content is 50 wt.%. The matrix material mainly provides the strength required for the support material; the water-soluble material mainly provides the water solubility of the support material; the compatibilizer is mainly used for Improve the compatibility between the matrix material and the soluble material of the material, and improve the processability; the filler is mainly used to increase the overall strength and modulus of the support material while reducing the cost.

[0038] A kind of preparation method that can be used for the support material of 3D printing described above, its specific steps are as follows:

[0039] (...

Embodiment 3

[0044] A support material that can be used for 3D printing. The support material is mainly composed of four parts: matrix material, soluble material, compatibilizer and filler. The weight percentage of each component is: matrix material content 5 wt.%, water soluble The material content is 90 wt.%, the compatibilizer content is 3 wt.%, and the filler content is 2 wt.%. The matrix material mainly provides the strength required for the support material; the water-soluble material mainly provides the water solubility of the support material; the compatibilizer is mainly used for Improve the compatibility between the matrix material and the soluble material of the material, and improve the processability; the filler is mainly used to increase the overall strength and modulus of the support material while reducing the cost.

[0045] A kind of preparation method that can be used for the support material of 3D printing described above, its specific steps are as follows:

[0046] (1)....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com