Road shoulder and medial strip filling machine

A central divider and filler machine technology, which is applied to earth movers/excavators, construction, etc., can solve the problems of vehicles falling into the slope, pollution of asphalt pavement, time-consuming and labor-intensive problems, so as to speed up construction and reduce construction costs. The effect of cost, modification and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

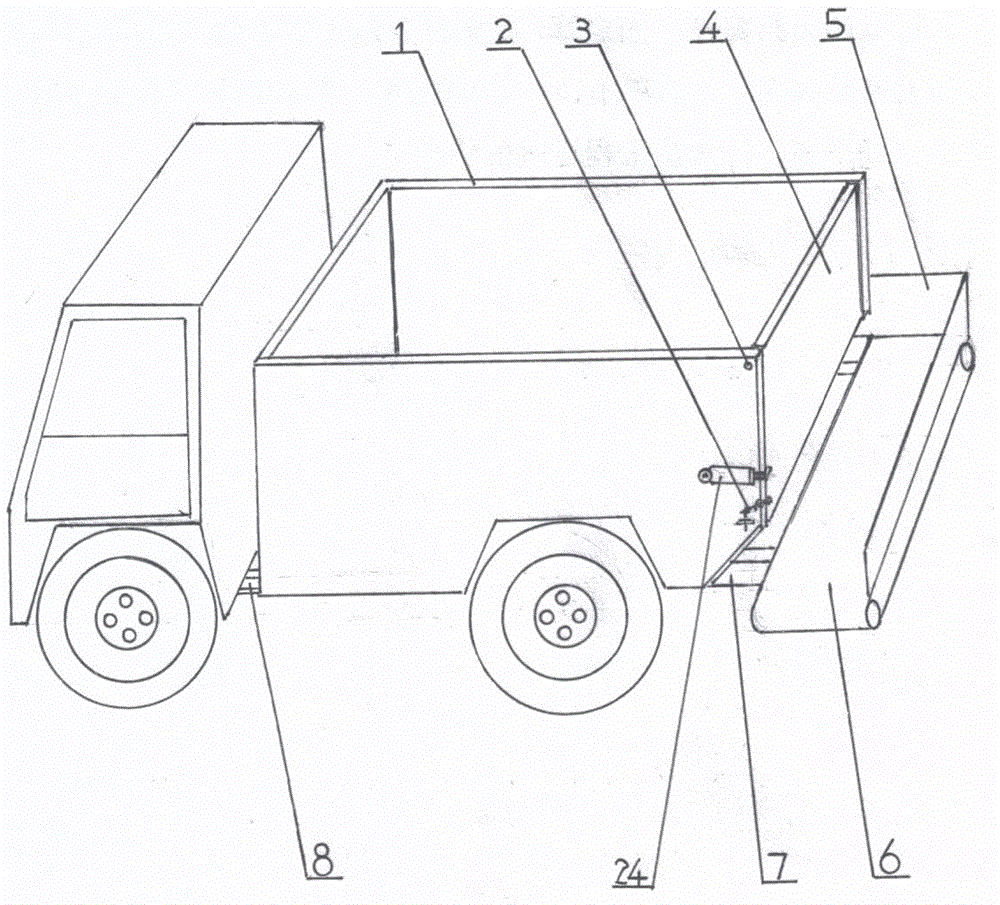

[0015] Such as Figure 1 to Figure 4 As shown, a road shoulder and central divider packing machine is composed of a dump truck and an engine. The dump truck is a traditional dump truck, including a compartment 1, wheels, an engine unit and a driver's cab, etc., so it will not be repeated. The rear end of the body frame 8 of the dump truck is connected with an extension frame 7, and the extension frame can be connected by bolts and integrated with the rear end of the body frame. The extension frame is provided with a conveyor belt device capable of transferring the loaded soil of the dump truck to the two sides of the truck. The conveyor belt 6 of the conveyor belt device is located at the lower end of the compartment tailgate 4 . The outer upper end of the conveyor belt of the conveyor belt device is provided with an L-shaped baffle plate 5 .

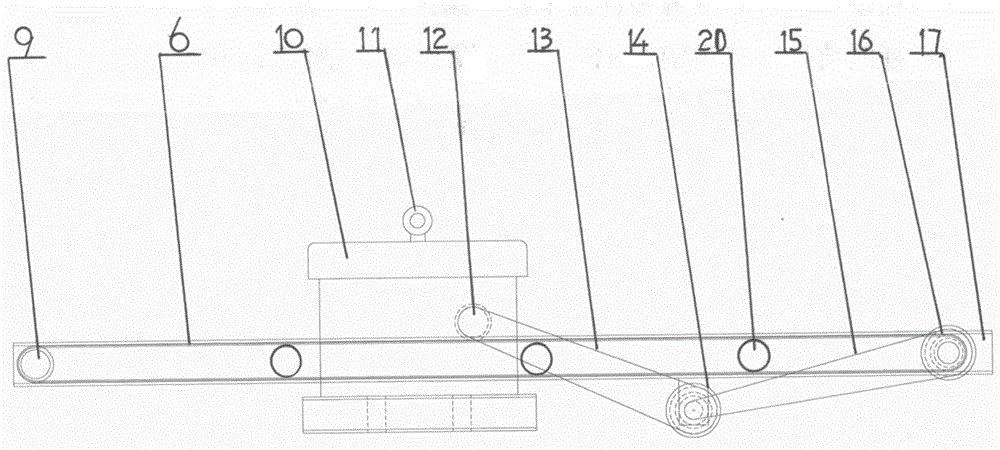

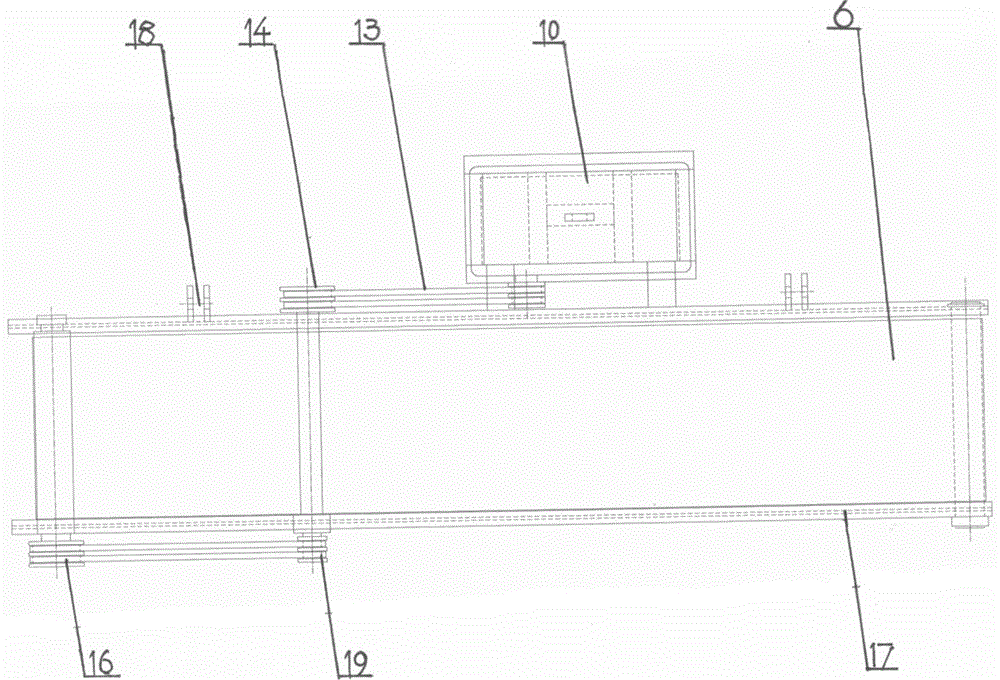

[0016] The transmission belt device includes: a transmission belt frame body 17, a motor 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com