Ribbed prestressed thin plate as well as casting mold and casting method thereof

A pouring mold and prestressing technology, applied in the direction of buildings, building components, building structures, etc., can solve problems such as insufficient strength, fracture, loss, etc., to avoid deformation or even fracture, improve project quality, and avoid losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

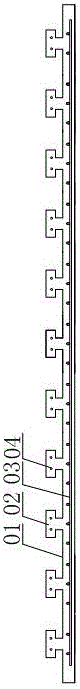

[0034] Please refer to figure 1 The ribbed prestressed sheet provided by the embodiment of the present invention includes a bottom plate 01 and a plurality of ribs 02 arranged on the bottom plate 01. The bottom plate 01 is provided with criss-crossing bottom plate reinforcement mesh 03, and the rib 02 is provided with ribs. Rebar 04.

[0035] The ribbed pre-stressed sheet provided by the embodiment of the present invention, because the bottom plate is provided with criss-crossed bottom plate steel bars, and the ribs are provided with ribbed steel bars, therefore, the strength at the ribs and the bottom plate can be strengthened to form The PK prestressed concrete composite slab has better strength, avoids deformation or even fracture, improves the quality of the project, and avoids unnecessary losses.

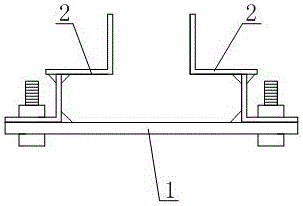

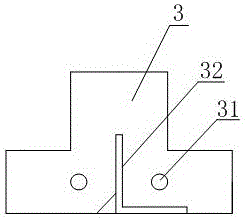

[0036] In a specific embodiment of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com