Speed raising tool for percussion drilling and method

A technology of percussion drilling and tools, which is applied to drilling equipment, driving devices for drilling in boreholes, earthwork drilling and production, etc. It can solve the problems of easy failure, fast seals, and wear of impact components, and achieves small length, simple structure, The effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

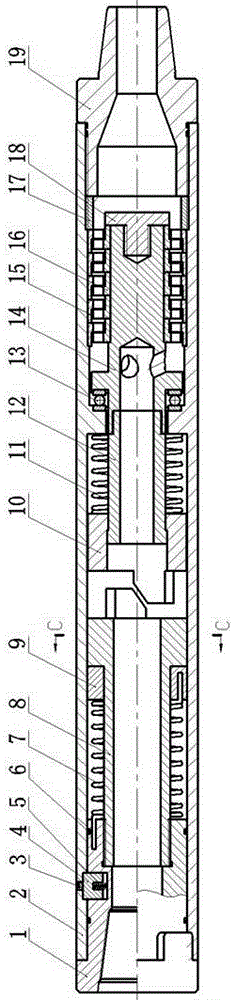

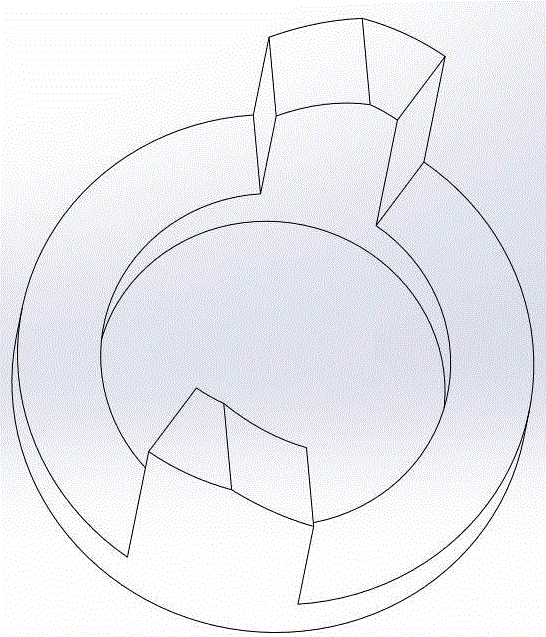

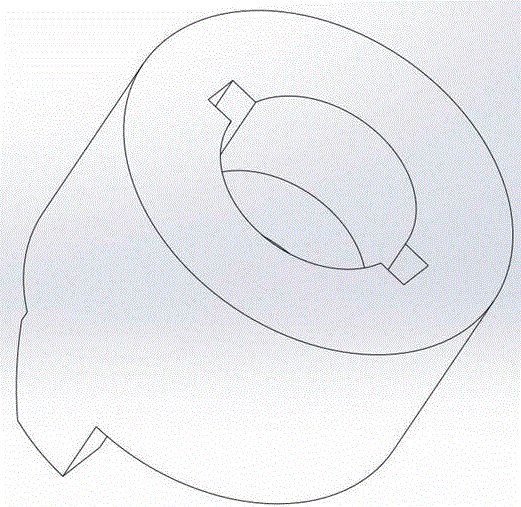

[0031] Such as Figure 1-Figure 4 As shown, an impact drilling speed-increasing tool is mainly composed of a transmission nipple 1, a housing 2, a nut 3, an anti-drop block 4, a radial spring 5, a sealing ring 6, a torsion spring 7, an impact shaft 8, and an impact hammer 9 , drive hammer 10, axial spring 11, drive shaft 12, thrust bearing 13, fixed shaft 14, turbine stator 15, turbine rotor 16, stator pressure cap 17, rotor pressure cap 18 and adapter 19, characterized in that The lower end of the impact shaft 8 is threadedly connected to the transmission pup joint 1, and the upper end of the impact shaft 8 is provided with two fan-shaped bumps; the impact hammer 9 is provided with two impact blocks and each impact block is provided with a The inclined surface subjected to the impact of the driving hammer 10, the lower end of the impact shaft 8 passes through the imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com