Lubricating grease paraffin and scale control oil production strip and application thereof

A technology of lubricating grease and oil production pipe, applied in drilling pipe, casing, earthwork drilling and other directions, can solve the problem of short service life of pipe and rod, affecting the normal production of oil well, and preventing wax or scale preventing device from both preventing wax at the same time. And anti-scaling and other issues, to achieve strong hydrophilic and oil repellency, prolong life and production efficiency, maintain the effect of normal production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

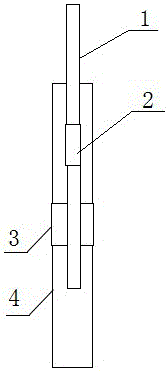

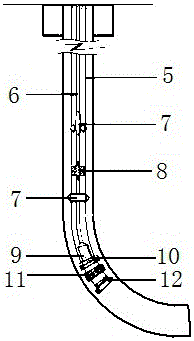

[0023] In order to solve the problem that most of the existing anti-wax or anti-scaling devices cannot simultaneously prevent wax and anti-scaling, resulting in a short service life of pipes and rods and affecting the normal production of oil wells, this embodiment provides such figure 1 The shown lubricating grease anti-wax and anti-scaling oil production string includes oil pipe 5 and oil sucker rod 6 in the oil pipe 5, and a oil pipe nipple 4 with a pipe medicine chamber 3 is installed under each oil pipe 5, The drug cavity 3 of the tube body is set on the short joint 4 of the tubing;

[0024] Below each sucker rod 6 is installed a sucker rod sub-section 1 with a rod drug cavity 2, and the rod drug cavity 2 is sleeved on the sucker rod sub-joint 1;

[0025] The tube drug cavity 3 and the rod drug cavity 2 have the same structure, both of which are annular cylinders closed at both ends, and the annular space is filled with solid grease. The inner wall of the tube drug cavity...

Embodiment 2

[0030] In order to solve the problem that most of the existing anti-wax or anti-scaling devices cannot simultaneously prevent wax and anti-scaling, resulting in a short service life of pipes and rods and affecting the normal production of oil wells, this embodiment provides such figure 1 The shown lubricating grease anti-wax and anti-scaling oil production string includes oil pipe 5 and oil sucker rod 6 in the oil pipe 5, and a oil pipe nipple 4 with a pipe medicine chamber 3 is installed under each oil pipe 5, The drug cavity 3 of the tube body is set on the short joint 4 of the tubing;

[0031] Below each sucker rod 6 is installed a sucker rod sub-section 1 with a rod drug cavity 2, and the rod drug cavity 2 is sleeved on the sucker rod sub-joint 1;

[0032] The tube drug cavity 3 and the rod drug cavity 2 have the same structure, both of which are annular cylinders closed at both ends, and the annular space is filled with solid grease. The inner wall of the tube drug cavity...

Embodiment 3

[0036] In order to solve the problem that most of the existing anti-wax or anti-scaling devices cannot simultaneously prevent wax and anti-scaling, resulting in a short service life of pipes and rods and affecting the normal production of oil wells, this embodiment provides such figure 1 The shown lubricating grease anti-wax and anti-scaling oil production string includes oil pipe 5 and oil sucker rod 6 in the oil pipe 5, and a oil pipe nipple 4 with a pipe medicine chamber 3 is installed under each oil pipe 5, The drug cavity 3 of the tube body is set on the short joint 4 of the tubing;

[0037] Below each sucker rod 6 is installed a sucker rod sub-section 1 with a rod drug cavity 2, and the rod drug cavity 2 is sleeved on the sucker rod sub-joint 1;

[0038] The tube drug cavity 3 and the rod drug cavity 2 have the same structure, both of which are annular cylinders closed at both ends, and the annular space is filled with solid grease. The inner wall of the tube drug cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com