A special thread gas-tight oil-casing joint for ultra-deep wells

A special thread and air-tight technology, applied in the direction of casing, drill pipe, drilling equipment, etc., can solve the problems of threaded joints that are prone to sticking, torque shoulder shear failure, uneven thread stress distribution, etc., so that it is not easy to trip , prevent yield failure, enhance the effect of fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

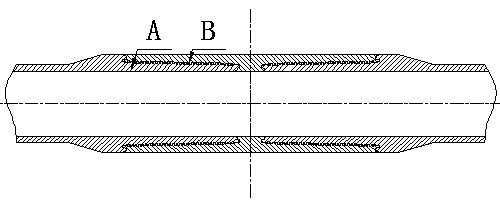

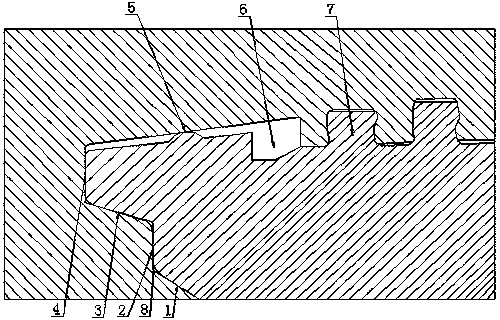

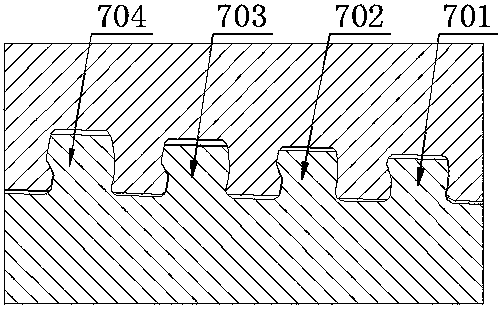

[0020] The oil-casing joint of the present invention is composed of a pipe body part A and a coupling part B, and the joint is composed of three-stage auxiliary sealing (-15° angle torque shoulder 1, right-angle torque shoulder 2, right-angle torque shoulder 4), two-stage The main seal (cone / cone seal structure 3, spherical / cone seal structure 5), relief groove 6, connecting thread 7, deformation release space 8 and so on. The spherical surface of the first main seal is on the male buckle, and the radius of the spherical surface is 40mm~60mm; the second main seal adopts a variable cone structure, and the taper of the female buckle is 1:10, and the taper of the male buckle is 1:8; deformation release The radius of the outer transition arc of the space is 1.2mm, and the radius of the inner transition arc is 0.6mm; the thread is a new type of thread structure designed on the basis of a partial trapezoidal thread, and its guide surface is based on a 5° partial trapezoidal thread gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com