Cyclic induction curtain grouting method for inclined shaft to penetrate through water-enriched compact quicksand stratum

A curtain grouting and inclined shaft technology is applied in the fields of support and reinforcement engineering and mine roadway excavation. Pore or crevice channels, the effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the accompanying drawings.

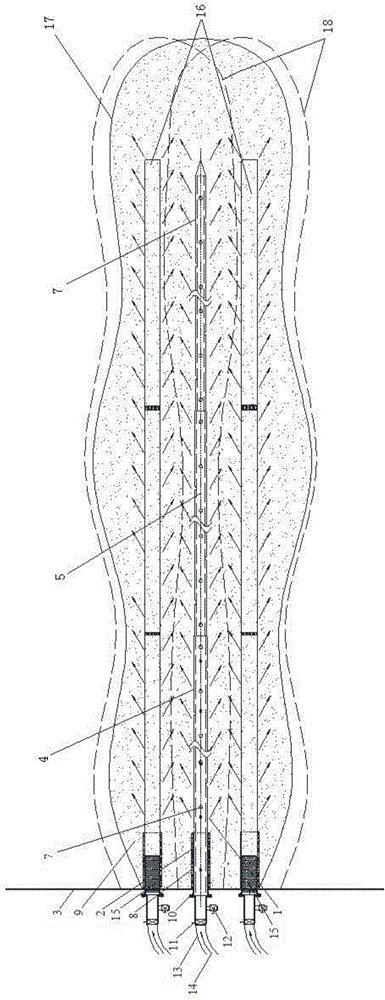

[0026] Such as figure 1 As shown, a kind of inclined well of the present invention passes through the water-rich tight flowing sand layer and circulates and induces curtain grouting method, comprises the following steps:

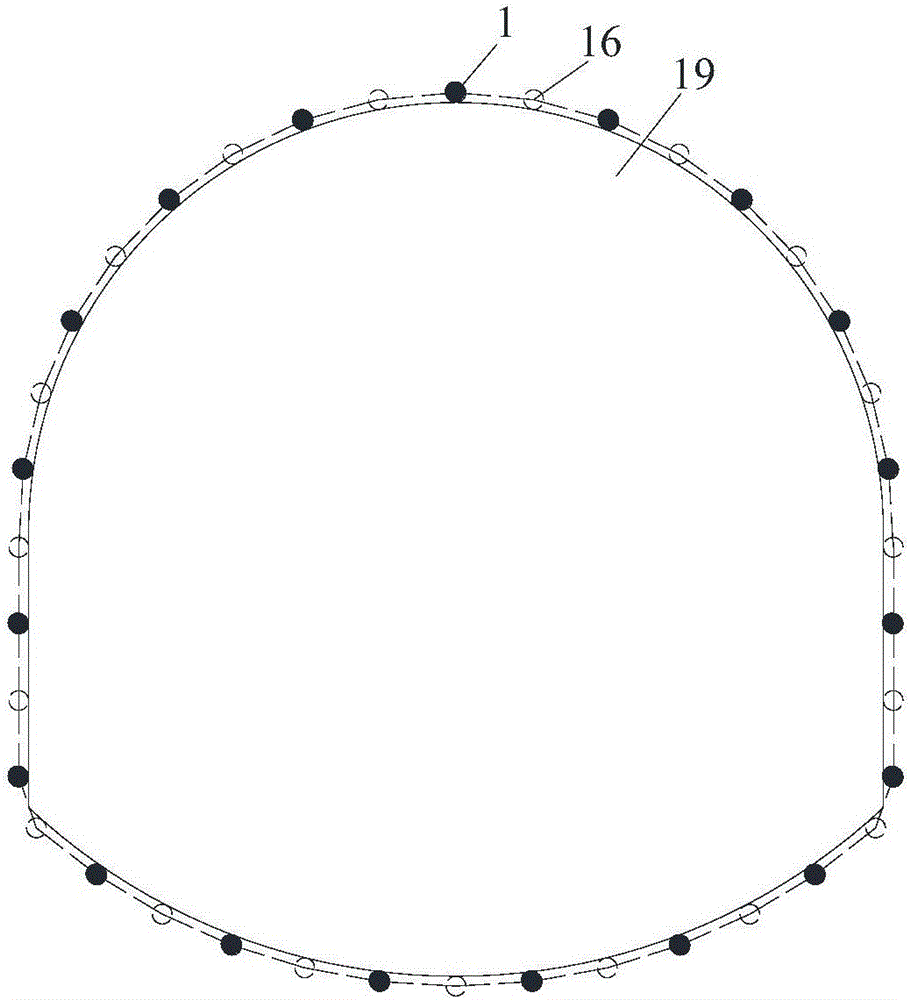

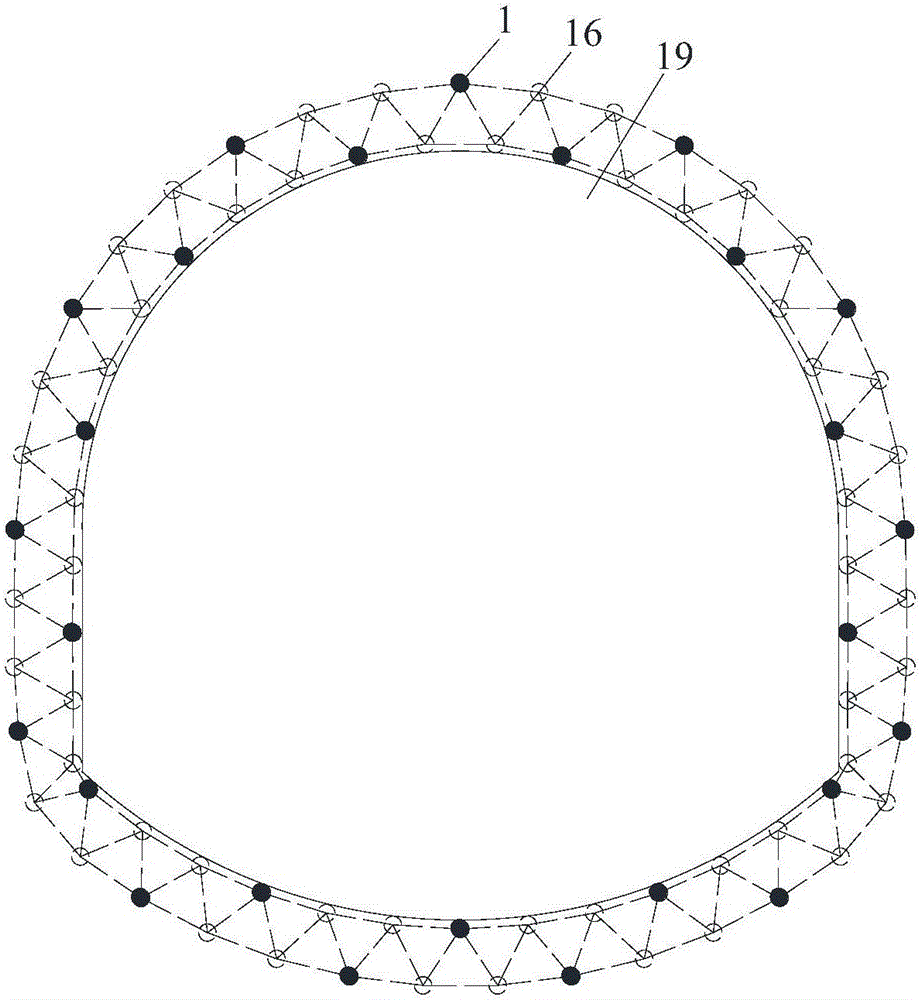

[0027] 1) Before the inclined shaft excavation face enters the quicksand layer, use shotcrete combined with metal mesh and steel brackets to seal the excavation face, and at the same time drive one or two laps into the front quicksand layer along the outer contour of the inclined shaft excavation face Or three circles of large-diameter orifice pipes, the orifice pipes are made of seamless steel pipes, the length is 2-3m, the diameter is 100-150mm, the wall thickness is 3-5mm, and the layout spacing is 0.5-0.8m. When the orifice tube is in one circle, it is arranged in a linear shape. When the orifice tube is in two circles, a triangle is formed betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com