Construction method for pouring tunnel second lining self-compacting concrete

A self-compacting concrete and construction method technology, applied in tunnel lining, tunnel, earthwork drilling and mining, etc., can solve the problems of uncompacted concrete filling, large concrete drop, concrete segregation, etc., to ensure the quality of the solid structure, high fluidity, Avoid the effect of exposed tendons and retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

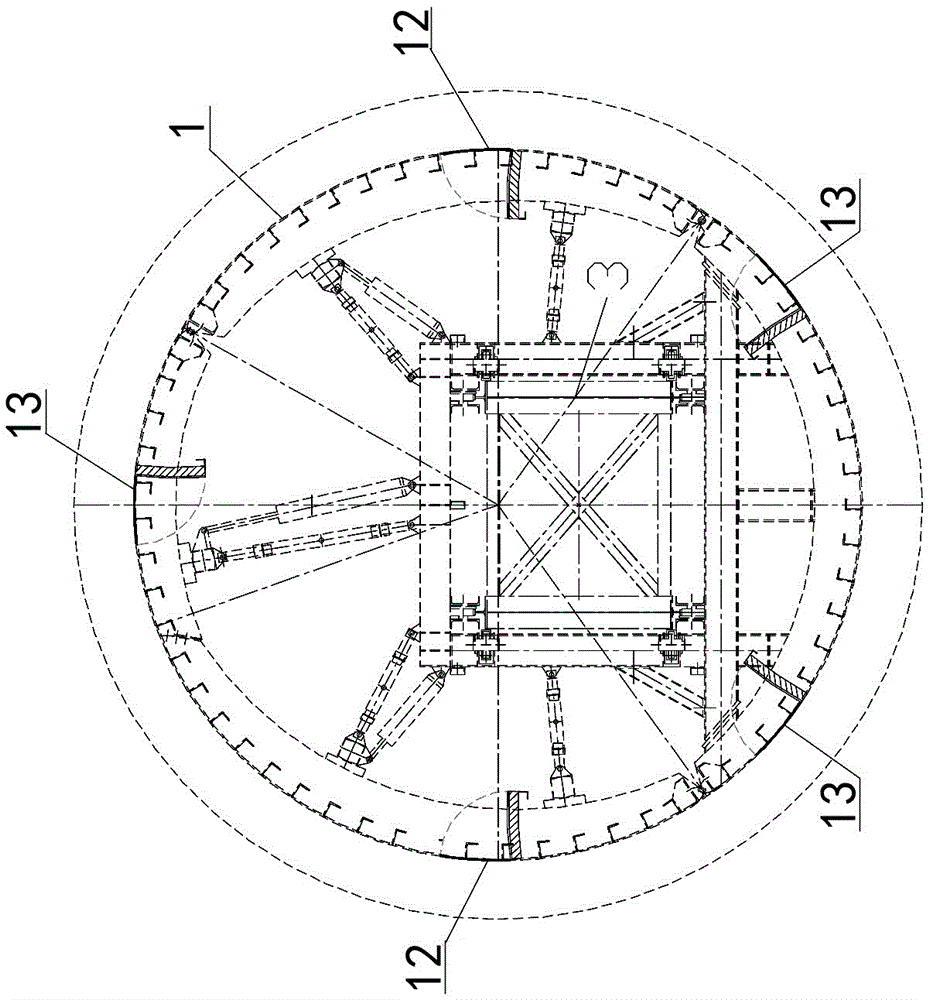

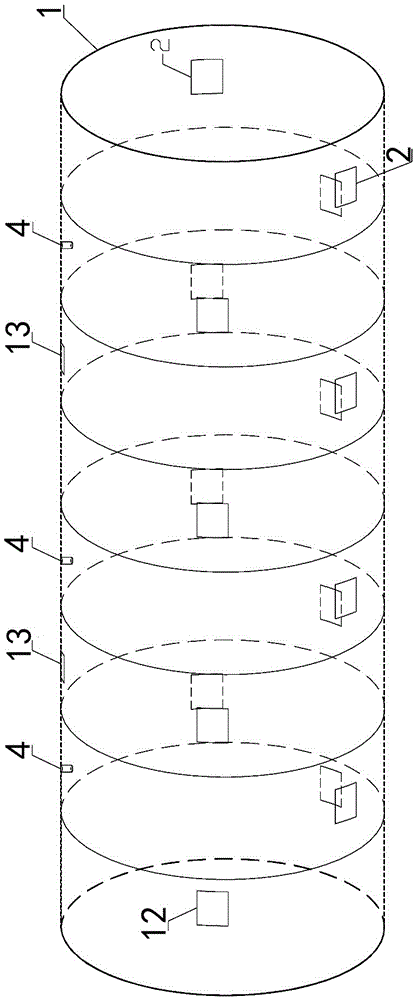

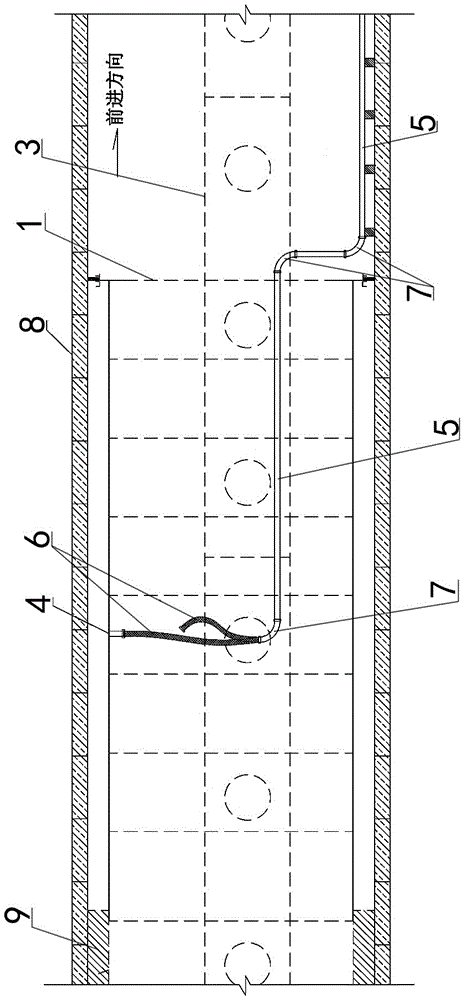

[0049] Examples see Figure 1-9 As shown, a construction method of pouring self-compacting concrete for the second lining of the tunnel is provided by taking the construction of self-compacting concrete for the second lining of the tunnel in the full-circle needle beam formwork trolley as an example. The second lining of the tunnel is a reinforced concrete lining structure with a certain thickness constructed on the base surface of the first lining of the tunnel after the construction of the first lining of the tunnel is completed. During the construction of the second lining of the tunnel, the formwork needs to be set up on the basis of the first lining of the tunnel. The use of full-circle needle beam formwork trolley formwork is currently the commonly used formwork method for circular tunnels. At the same time, it is difficult to vibrate the concrete in the circular formwork space. , using vibration-free self-compacting concrete for pouring.

[0050] The specific construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com