A Direct Energy Balance Coordinated Control System for Large Circulating Fluidized Bed Units

A technology of coordinated control system and circulating fluidized bed, which is applied in the direction of control system, fluidized bed combustion equipment, fuel burned in melting state, etc., can solve the unsatisfactory control effect of the coordinated control system of circulating fluidized bed unit The steam pressure fluctuates greatly, and the variable load rate of the unit is difficult to meet the assessment indicators, etc., to achieve the effect of solving the low load response rate, ensuring safe and stable operation, and solving the large fluctuation of the main steam pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

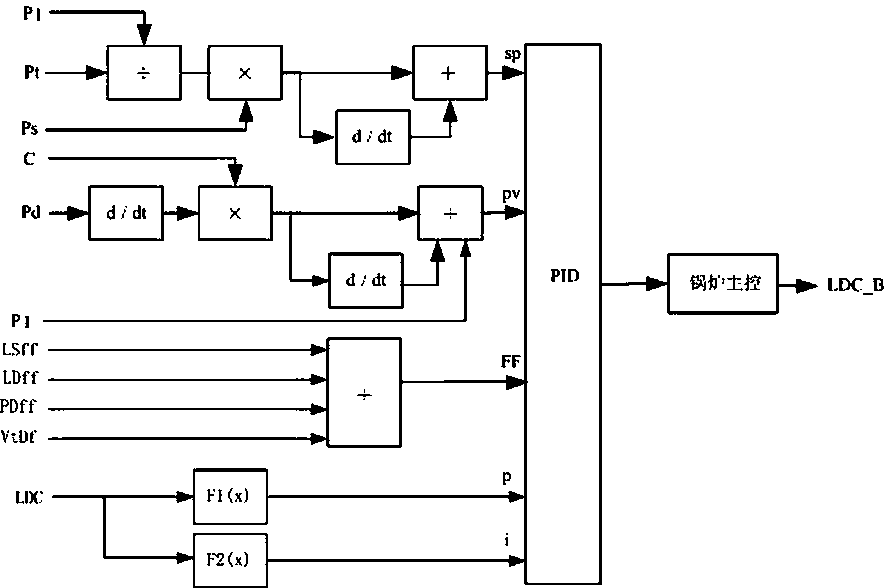

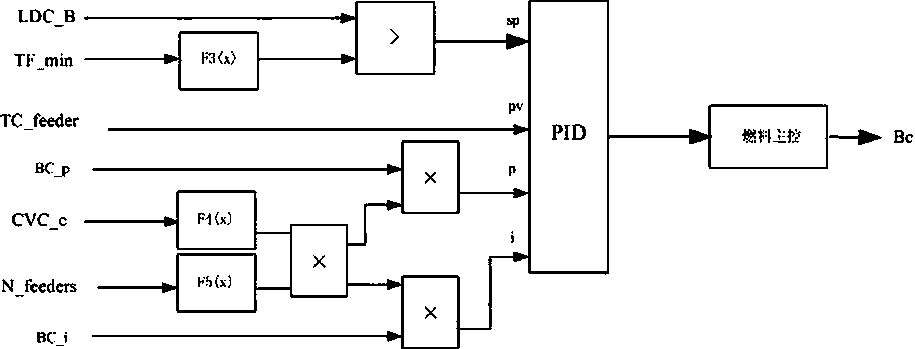

[0019] Combine below Figure 1~Figure 2 And embodiment the present invention is described further.

[0020] Such as Figure 1~Figure 2 As shown, this embodiment includes a boiler main control controller, a fuel main control controller and a steam turbine main control controller; the boiler main control controller adopts a steam drum heat signal with a second order differential and a dynamic and static feedforward signal . The heat signal of the second-order differential can more accurately represent the heat signal of the boiler drum than the heat signal of the first-order differential, which improves the adjustment quality of the main control controller of the boiler to a certain extent.

[0021] The dynamic and static feedforward signals include the static feedforward signal LSff of the unit load command to the boiler fuel, the dynamic feedforward signal LDff of the unit load command to the boiler fuel, the dynamic feedforward signal PDff of the unit pressure to the boiler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com