Application of solar-energy-phase-change heat storage technology and waste heat recovery technology to prefabricated concrete member maintenance process

A technology of prefabricated concrete and phase change heat storage, which is applied in solar thermal energy, solar thermal power generation, solar collectors, etc., can solve the problems of high energy consumption, achieve energy saving, reduce maintenance process energy consumption, and reduce carbon emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

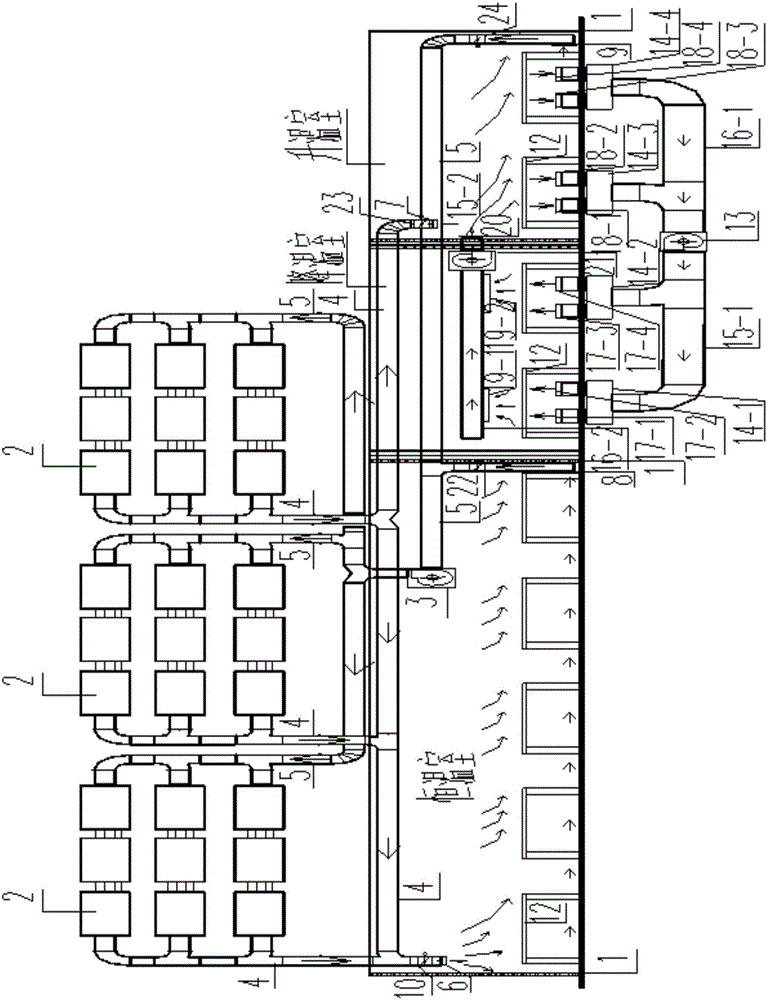

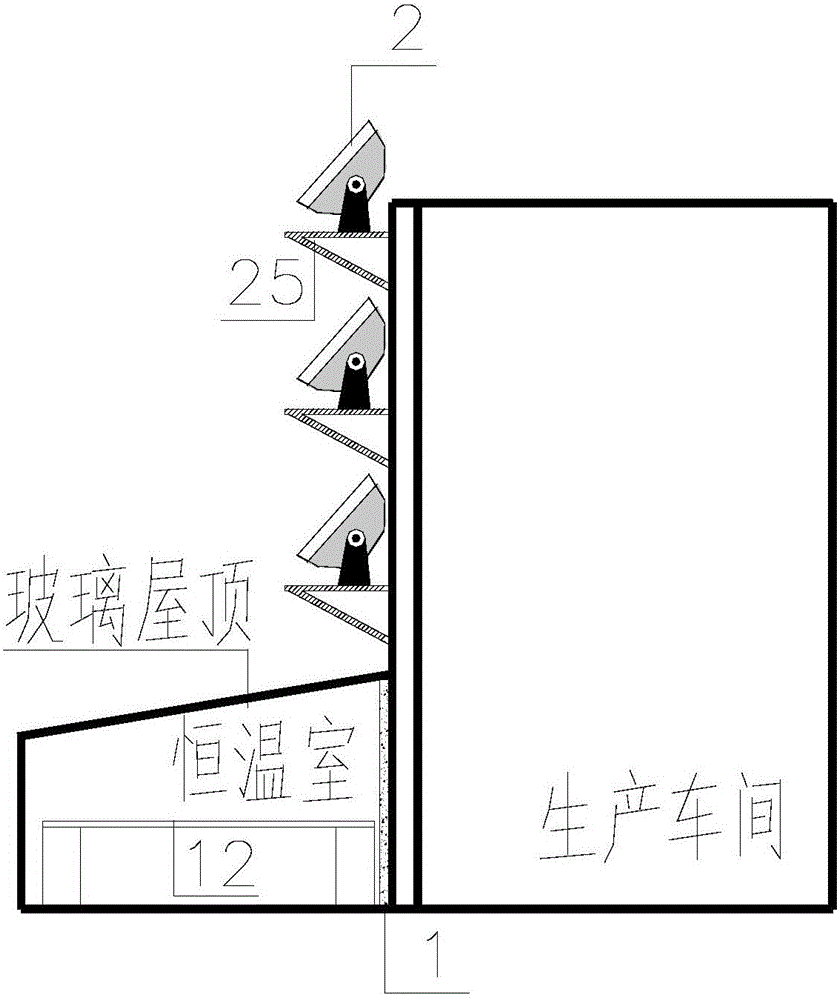

[0025] Based on the optimized maintenance process of precast concrete components, return air outlets, ventilation ducts and axial flow fans are set under the precast concrete component formwork in the heating room, and air supply outlets and ventilation ducts are set under the precast concrete component formwork in the cooling room. The construction area of the heating room and cooling room is 500 square meters, and the air volume of the fan is 18000m 3 / h, the size of each air outlet is 800mmx200mm, the wind speed is 2m / s, the distance between the air supply port and the bottom of the mold table is 150mm, and the wind speed in the air duct is 3m / s to 7m / s. The low-temperature air under the mold table of the heating room is sent to the mold table of the cooling room through the ventilation duct and the fan, and blows to the mold table. The low-temperature air is forced to exchange heat with the 50-60°C prefabricated concrete components that come out of the constant temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com