Variable-atmosphere pressure heat conductivity coefficient testing device based on transient plane source method

A transient plane, thermal conductivity technology, applied in the field of measurement, can solve the problems of discontinuous test results, low preparation requirements, large sample requirements, etc., to achieve the effect of low test sample requirements, simple system, and improved test upper limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

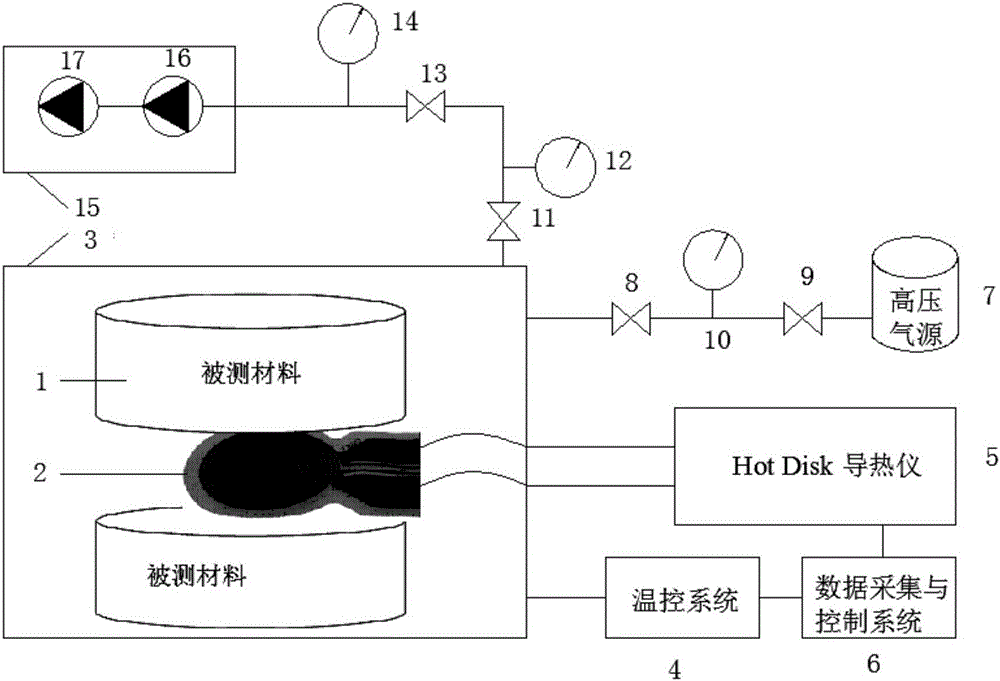

[0019] Such as figure 1 As shown, a variable atmosphere pressure thermal conductivity test device based on the transient plane heat source method of the present invention includes a material to be tested 1, a double-helix test probe 2, a tubular high-temperature furnace 3, a temperature control system 4, and a Hot Disk thermal conductivity instrument 5 , data acquisition and control system 6, high pressure gas source 7, first control valve 8, second control valve 9, pressure gauge 10, third control valve 11, first vacuum gauge 12, fourth control valve 13, second vacuum Meter 14 and molecular pump set 15, wherein the molecular pump set 15 includes a mechanical pump 16 and a molecular pump 17.

[0020] When using the Hot Disk thermal conductivity meter 5 based on the transient plane heat source method to test the thermal conductivity, the double-helix test pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com