Apparatus and method for reinforcing column by prestressed fiber sheet

A fiber sheet and prestressing technology, which is applied in building maintenance, construction, building construction, etc., can solve the problems that there are no prestressed fiberboard reinforcement columns, and the large-scale promotion of projects cannot be implemented, so as to facilitate popularization and use and improve strength Utilization, the effect of controlling the development of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

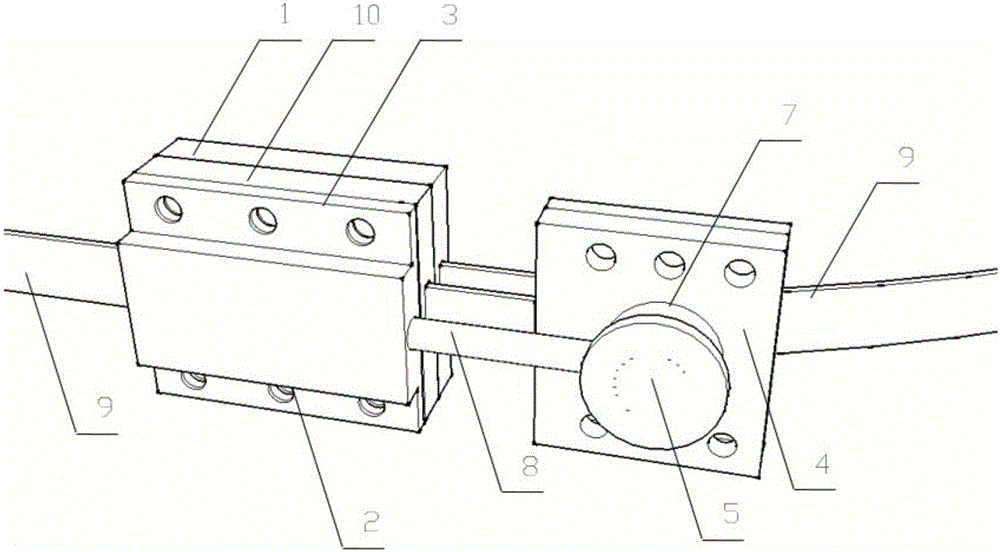

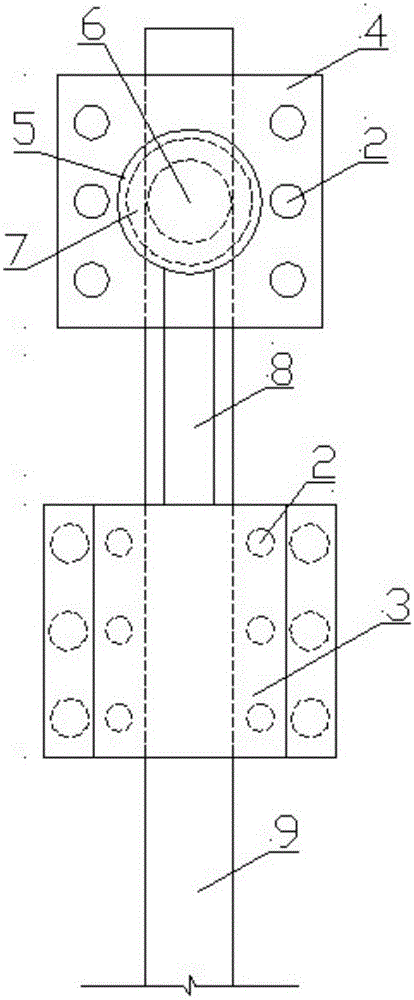

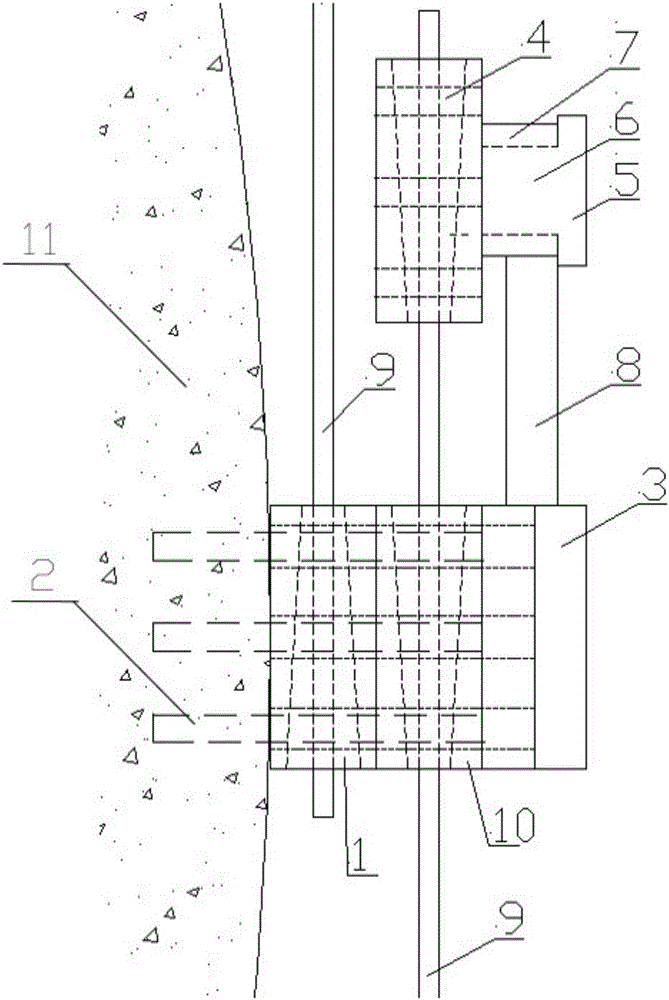

[0030] like figure 1 , figure 2 , image 3 As shown, a device for reinforcing a column with a prestressed fiber sheet of the present invention includes a fixed-end anchor 1 anchored on a concrete column 11, a tension-end anchor 10, and a fixed-end anchor 1 and a tension-end anchor. A convex hydraulic jack 3 connected with a tool 10; also includes a two-part clamp 4, a cylinder 6 with a column cap 5 is welded to the upper surface of the clamp 4, and the sleeve 7 nested outside the cylinder 6 is pressed The rod 8 is connected to the convex hydraulic jack 3; one end of the fiber sheet 9 is clamped by the clip-type clamp 4 at the tension end, and the other end is anchored to the fixed end anchor 1, the fixed end anchor 1, and the tension end anchor 10 It is composed of an anchor cup and a clip, and there are two sets of threaded holes on the anchor cup, one set of hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com