Horizontal well dragging type liquid producing section testing tubular column and testing method thereof

A liquid production profile and test tube technology, which is applied in the directions of measurement, earthwork drilling and production, wellbore/well components, etc., can solve the problems of test result distortion, low test response, and segmental test difficulties, etc., to reduce data errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

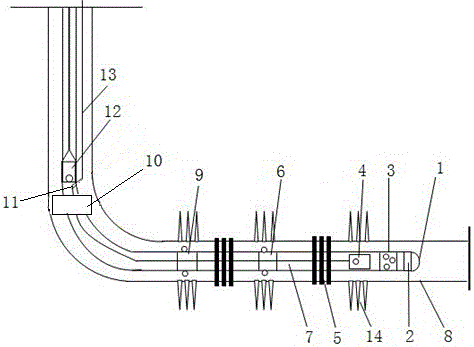

[0027] In order to overcome the deficiencies of the existing technology and provide a basis for the adjustment of water injection development of horizontal wells and the purpose of water plugging in the later stage, this embodiment provides a method such as figure 1 The shown horizontal well dragging liquid production profile test string includes tubing 7 and casing 8. The tubing 7 is located inside the casing 8 and includes a horizontal section and a vertical section. The horizontal section of the tubing 7 starts from the toe There are guide plug 1, eye pipes 3, 4, connecting pipe 1 6 and connecting pipe 2 9 in order from the bottom to the heel, oil well pump 12 is arranged in the vertical section of oil pipe 7, and the output profile tester 4 is connected with Cable 13, and the cable 13 is connected to the wellhead equipment through the three-way guide pipe 11 provided at the bottom of the oil well pump 12 in the vertical section of the tubing 7, and the horizontal section of...

Embodiment 2

[0037] On the basis of embodiment 1, this embodiment provides a kind of figure 1 The shown horizontal well dragging liquid production profile test string includes tubing 7 and casing 8. The tubing 7 is located inside the casing 8 and includes a horizontal section and a vertical section. The horizontal section of the tubing 7 starts from the toe There are guide plug 1, eye pipes 3, 4, connecting pipe 1 6 and connecting pipe 2 9 in order from the bottom to the heel, oil well pump 12 is arranged in the vertical section of oil pipe 7, and the output profile tester 4 is connected with Cable 13, and the cable 13 is connected to the wellhead equipment through the three-way guide pipe 11 provided at the bottom of the oil well pump 12 in the vertical section of the tubing 7, and the horizontal section of the casing 8 is provided with a plurality of perforation sections 14.

[0038] Further, a Y221 packer 10 is provided at the same position below the vertical section of the tubing 7 and...

Embodiment 3

[0041] On the basis of embodiment 2, this embodiment provides a kind of figure 1The shown horizontal well dragging liquid production profile test string includes tubing 7 and casing 8. The tubing 7 is located inside the casing 8 and includes a horizontal section and a vertical section. The horizontal section of the tubing 7 starts from the toe There are guide plug 1, eye pipes 3, 4, connecting pipe 1 6 and connecting pipe 2 9 in order from the bottom to the heel, oil well pump 12 is arranged in the vertical section of oil pipe 7, and the output profile tester 4 is connected with Cable 13, and the cable 13 is connected to the wellhead equipment through the three-way guide pipe 11 provided at the bottom of the oil well pump 12 in the vertical section of the tubing 7, and the horizontal section of the casing 8 is provided with a plurality of perforation sections 14.

[0042] Further, pins are provided at both ends of the connecting pipe 1 6 and the connecting pipe 2 9. When the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com