Small-diameter pipe inside weld surface defect identification device

A technology for weld surface and defect identification, applied in the field of non-destructive testing, can solve problems such as eye fatigue, missed inspection, and large subjective factors affecting inspectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Below in conjunction with concrete experiment the present invention will be further described:

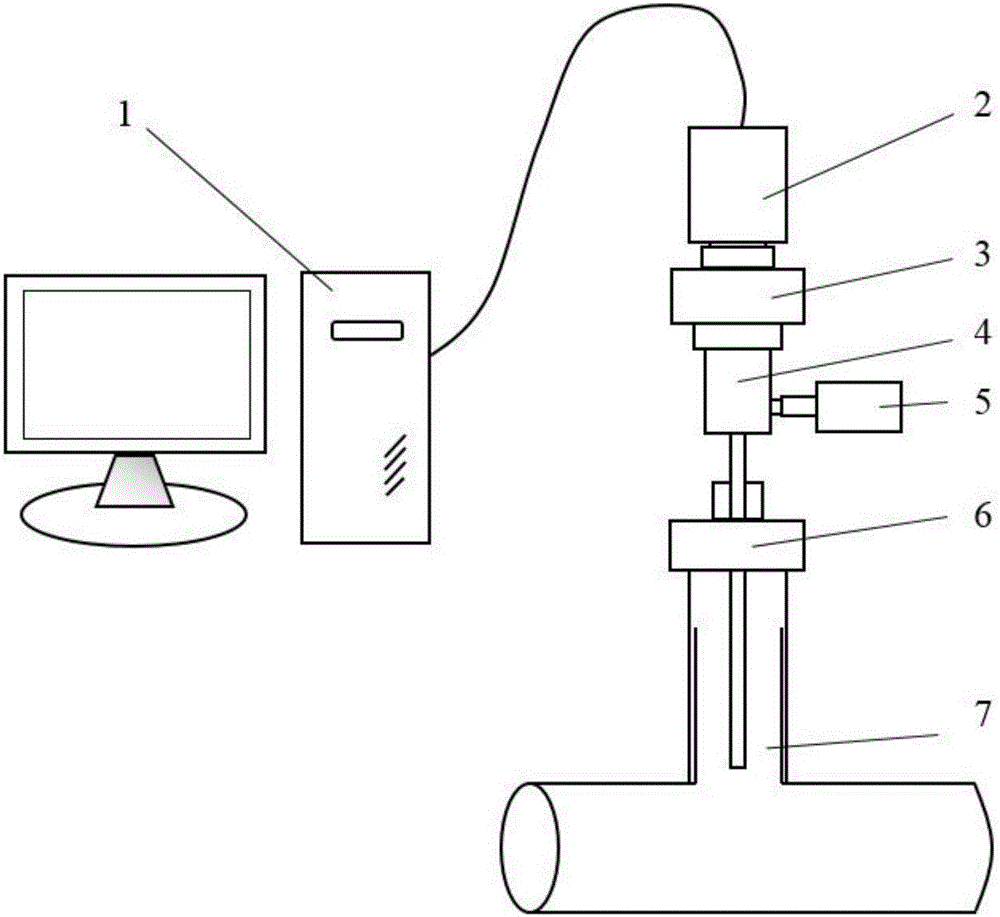

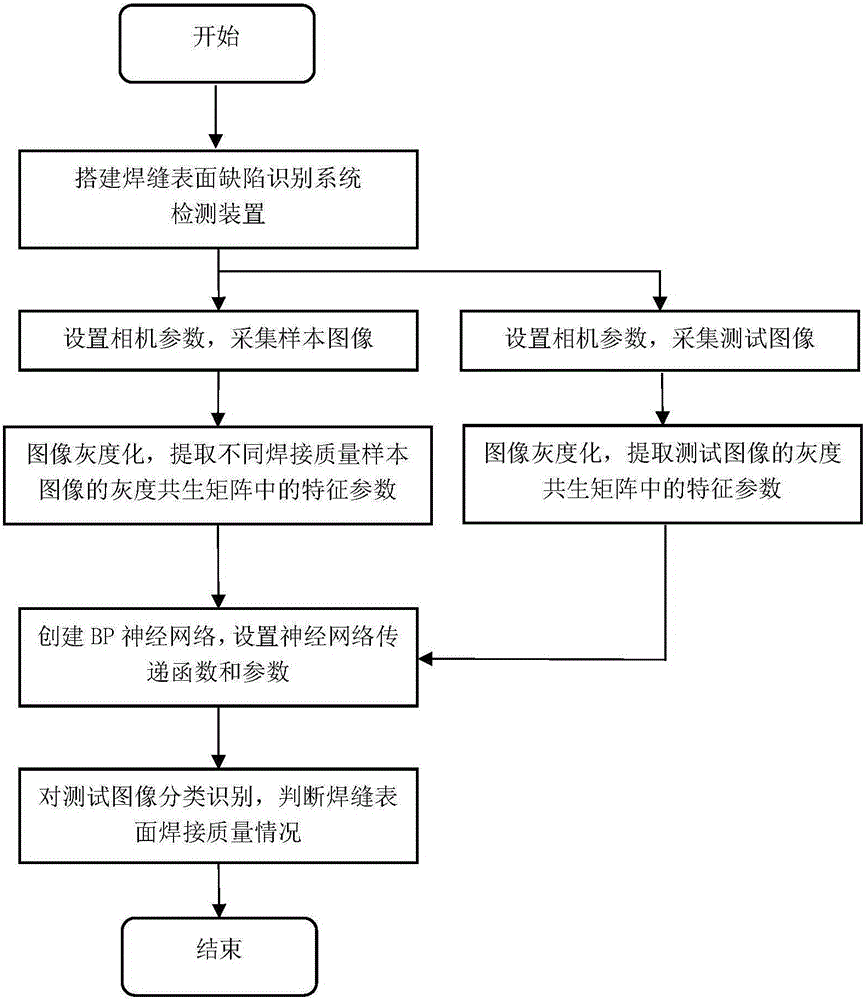

[0064] Step 1: Build the experimental system: according to figure 1 The system diagram of the detection device installation test system, the system includes a computer 1, an industrial camera 2 with a volume of 29mm×29mm×57mm, an F35 optical adapter 3, an industrial rigid endoscope with a diameter of 8mm 4, a mobile portable light source 5 and an endoscope Fixture 6. The industrial camera 2 is connected with the computer 1, one end of the adapter 3 is connected with the industrial camera 2, and the other end is connected with the industrial endoscope 4, which can be used for the collection of welding seam images. The mobile portable light source 5 is connected with the industrial endoscope 4 for providing illumination in the tube. The endoscope fixing fixture 6 is connected with the endoscope 4, and is used for central positioning and up and down adjustment and positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com