A variable stroke electromechanical actuator

An electromechanical actuator and stroke technology, which is applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of high cost, poor redundancy and poor reliability of electromechanical actuators, and improve the output accuracy of the system and reliability, improving system redundancy and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below by embodiment the present invention will be further described:

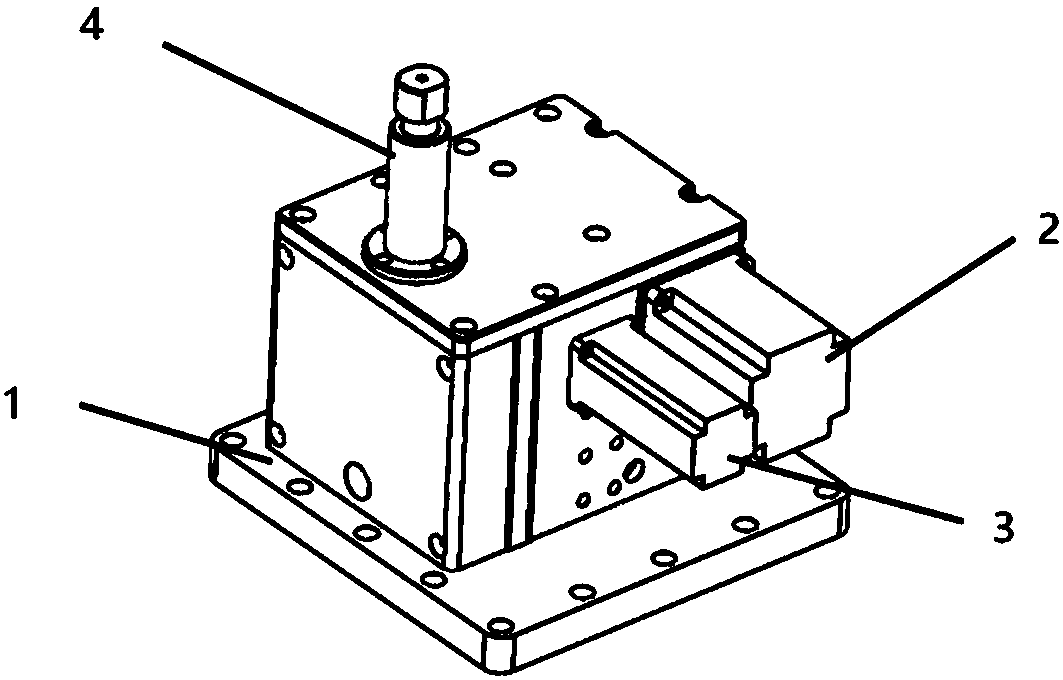

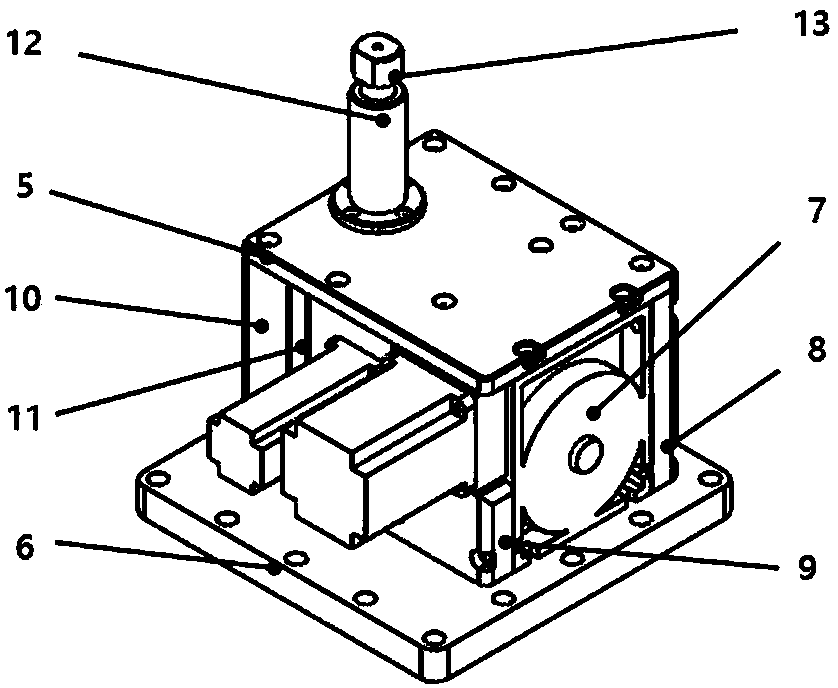

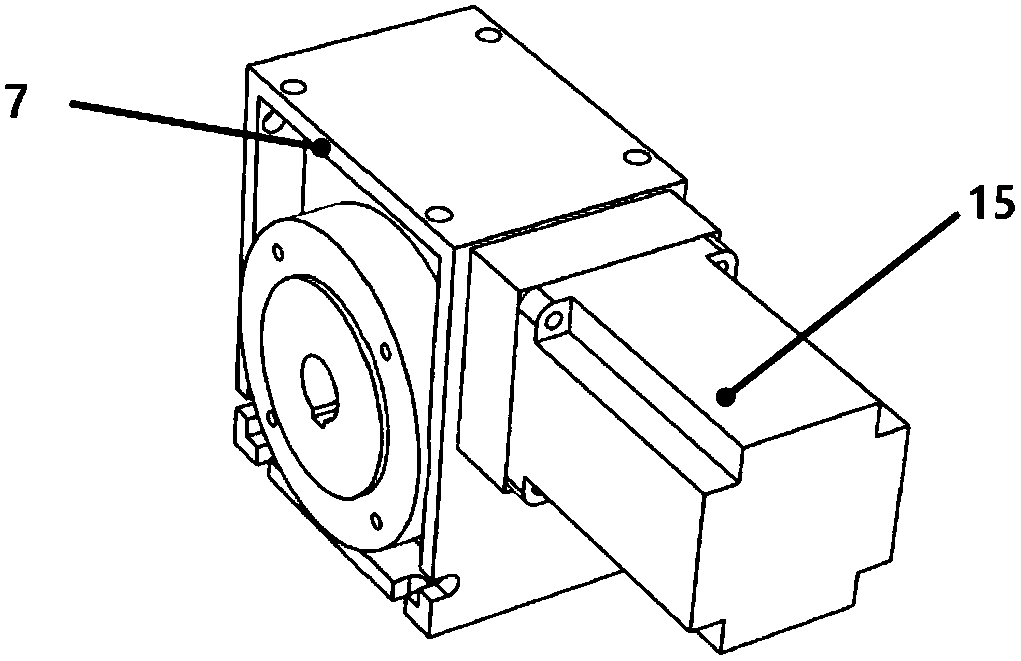

[0038] A variable-stroke electromechanical actuator of the present invention is composed of a frame unit 1, a drive unit 2, a variable-stroke unit 3, and an output unit 4. The schematic diagram of the installation structure is as follows figure 1 shown. Wherein the bottom surface of the speed reducer 7 of the drive unit 2 is fixed on the bottom surface of the frame unit 1 by fasteners, the speed reducer 7 of the drive unit 2 is connected with one end of the speed reducer output shaft 19 of the variable stroke unit 3 through a key, and the speed reducer The other end of the output shaft 19 is connected to the flywheel shaft connector 23 of the output unit 4 through the fixed threaded adjustment member 20 to realize transmission control, and the flywheel traveling connecting rod 29 of the variable stroke unit 3 is connected to the crank connecting rod 30 of the output unit 4 Connected to adjust the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com